A needle valve provides precise flow control by regulating the passage of liquids or gases through a small, tapered needle-shaped plunger. This valve is ideal for applications requiring fine adjustments, such as in instrumentation and hydraulic systems. Discover how needle valves enhance your system's efficiency and reliability by reading the full article.

Table of Comparison

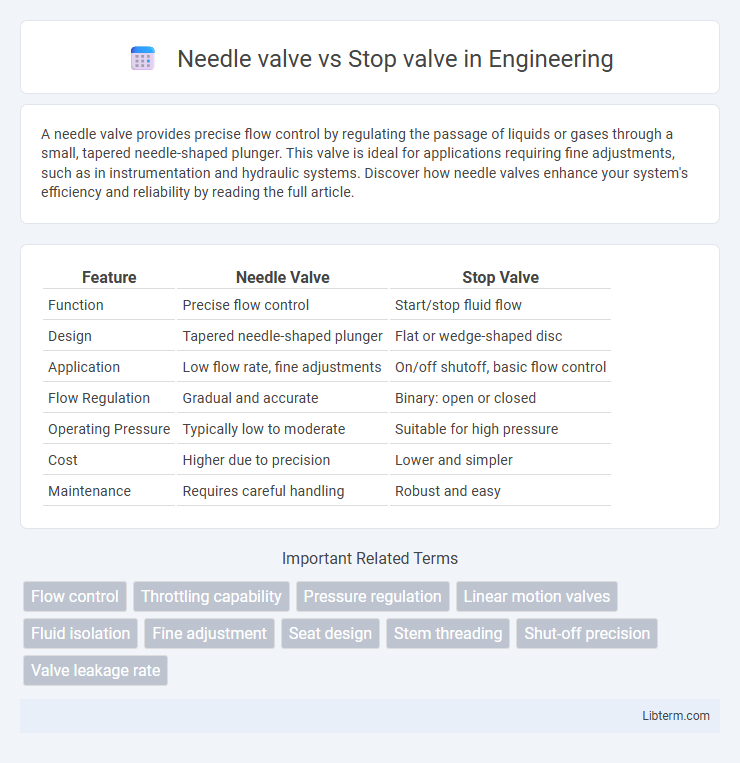

| Feature | Needle Valve | Stop Valve |

|---|---|---|

| Function | Precise flow control | Start/stop fluid flow |

| Design | Tapered needle-shaped plunger | Flat or wedge-shaped disc |

| Application | Low flow rate, fine adjustments | On/off shutoff, basic flow control |

| Flow Regulation | Gradual and accurate | Binary: open or closed |

| Operating Pressure | Typically low to moderate | Suitable for high pressure |

| Cost | Higher due to precision | Lower and simpler |

| Maintenance | Requires careful handling | Robust and easy |

Overview of Needle Valves and Stop Valves

Needle valves provide precise flow control through a slender, tapered needle that fits into a matching seat, enabling fine regulation in low-flow applications. Stop valves function primarily as on/off devices, utilizing a flat disc or plug to completely block or allow fluid flow in pipelines. While needle valves excel in accuracy and throttling capabilities, stop valves prioritize straightforward flow interruption and sealing efficiency.

Key Design Differences

Needle valves feature a slender, tapered needle-like plunger that allows precise flow control, making them ideal for low-flow and high-pressure applications. Stop valves utilize a flat or disc-shaped closure element that provides a quick shut-off but less fine-tuning capability. The key design difference lies in the needle valve's ability to regulate flow in small increments, whereas stop valves prioritize on/off functionality with straightforward operation.

Functionality and Working Principles

Needle valves provide precise flow control by using a slender, tapered needle that fits into a matching seat to finely adjust fluid flow, making them ideal for applications requiring accurate regulation. Stop valves function by fully opening or closing the flow path via a flat or wedge-shaped disc that moves perpendicular to the flow, primarily used for isolation rather than control. The working principle of needle valves relies on gradual throttling through needle positioning, while stop valves operate on a binary mechanism, ensuring complete stoppage or full passage of the fluid.

Common Applications

Needle valves are commonly used in precise flow control applications such as fuel regulation systems, hydraulic lines, and instrumentation panels where fine adjustment of fluid flow is critical. Stop valves find widespread use in residential plumbing, industrial piping, and gas supply systems for quick shut-off and isolation of fluid flow. Both valves serve important roles in controlling fluid dynamics, with needle valves excelling in accuracy and stop valves prioritizing on/off functionality.

Flow Control Precision Comparison

Needle valves offer superior flow control precision due to their fine-threaded stem, which allows for incremental adjustments and stable regulation of fluid flow, making them ideal for low-flow applications requiring exact settings. Stop valves provide more straightforward on/off control and are less effective for precise flow modulation, as their larger valve seats result in coarser adjustment increments. The inherent design differences make needle valves preferable where accurate flow rates and smooth throttling are critical, while stop valves suit applications prioritizing full shutoff or unrestricted flow.

Pressure Handling Capabilities

Needle valves offer precise control of fluid flow and are designed to handle high-pressure systems with minimal leakage due to their fine-threaded stem and tight seal. Stop valves, while suitable for on/off control applications, generally have lower pressure handling capabilities and are less effective in maintaining fine flow adjustments under high pressure. The robust construction of needle valves ensures superior performance in high-pressure environments compared to the simpler design of stop valves.

Installation and Maintenance Considerations

Needle valves require precise installation to ensure accurate flow control, often positioned where fine adjustment is critical, typically in instrumentation lines; maintenance involves regular inspection of the needle and seat for wear to prevent leaks and ensure smooth operation. Stop valves are generally installed for on/off control in pipelines and require straightforward placement with accessible handles for manual operation; maintenance focuses on checking the valve seat and packing for tight shutoff and ease of turning. Proper installation and routine maintenance of both valve types are essential to maintain system integrity and prevent operational failures.

Cost and Material Differences

Needle valves are typically made from corrosion-resistant materials like stainless steel or brass, which increase their cost compared to stop valves that often use cast iron or carbon steel. The precise control mechanism in needle valves requires tighter manufacturing tolerances, making them more expensive than the simpler design of stop valves. Stop valves generally offer a cost-effective solution for basic on/off control, while needle valves incur higher costs due to their material quality and precision engineering.

Advantages and Disadvantages

Needle valves provide precise flow control due to their fine threaded stem design, making them ideal for applications requiring accurate adjustments, but they are limited by lower flow capacity and higher pressure drops. Stop valves offer straightforward on/off functionality with minimal pressure loss, suitable for quick shut-off in pipeline systems, though they lack the capability for fine flow regulation. Choosing between the two depends on the need for precision control versus simple operation and flow capacity requirements.

How to Choose Between Needle Valve and Stop Valve

Choosing between a needle valve and a stop valve depends on the required precision and flow control in a system. Needle valves provide accurate regulation of flow rates with fine adjustments, ideal for low-flow applications or systems needing precise control. Stop valves are better suited for quickly shutting off or isolating flow in pipelines, especially in higher flow or pressure scenarios where simple on/off functionality is needed.

Needle valve Infographic

libterm.com

libterm.com