Spray drying is an efficient technique for transforming liquid substances into dry powders by rapidly drying with hot gas. This process preserves the quality and stability of heat-sensitive materials, making it ideal for pharmaceuticals, food products, and chemicals. Discover how spray drying can optimize your production workflow by reading the full article.

Table of Comparison

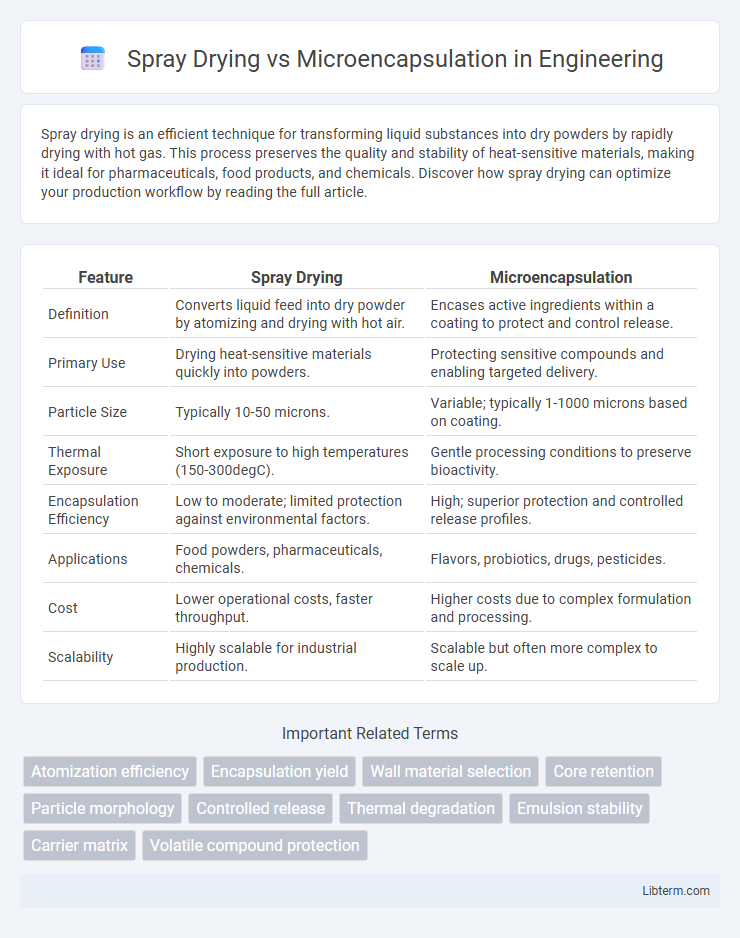

| Feature | Spray Drying | Microencapsulation |

|---|---|---|

| Definition | Converts liquid feed into dry powder by atomizing and drying with hot air. | Encases active ingredients within a coating to protect and control release. |

| Primary Use | Drying heat-sensitive materials quickly into powders. | Protecting sensitive compounds and enabling targeted delivery. |

| Particle Size | Typically 10-50 microns. | Variable; typically 1-1000 microns based on coating. |

| Thermal Exposure | Short exposure to high temperatures (150-300degC). | Gentle processing conditions to preserve bioactivity. |

| Encapsulation Efficiency | Low to moderate; limited protection against environmental factors. | High; superior protection and controlled release profiles. |

| Applications | Food powders, pharmaceuticals, chemicals. | Flavors, probiotics, drugs, pesticides. |

| Cost | Lower operational costs, faster throughput. | Higher costs due to complex formulation and processing. |

| Scalability | Highly scalable for industrial production. | Scalable but often more complex to scale up. |

Introduction to Spray Drying and Microencapsulation

Spray drying is a widely used technique that transforms liquid feed into dry powder by rapidly drying with a hot gas, preserving the material's properties and ensuring stability. Microencapsulation involves enclosing active ingredients within a protective coating to enhance controlled release, improve shelf life, and mask odors or flavors. Both technologies serve critical roles in pharmaceuticals, food, and chemical industries by improving product functionality and protecting sensitive compounds.

Core Principles and Processes

Spray drying involves converting liquid feed into dry powder by rapidly drying with a hot gas, optimizing particle size and moisture content for stability. Microencapsulation encloses active ingredients within a protective coating to enhance shelf life, control release, and improve handling. Both processes are essential in pharmaceuticals and food industries for preserving sensitive compounds and ensuring targeted delivery.

Materials Used in Each Technique

Spray drying utilizes a range of materials including carbohydrates like maltodextrin, proteins such as whey or casein, and gum derivatives like gum arabic to form stable powders by rapid solvent evaporation. Microencapsulation often employs polymers such as alginate, chitosan, or synthetic polymers like ethylcellulose to create protective coatings around core materials, enhancing controlled release and stability. Both techniques select encapsulating agents based on the desired functionality, compatibility with core substances, and environmental resistance required for specific applications.

Key Differences in Mechanisms

Spray drying transforms liquid feed into dry powder by atomizing the liquid into a hot air chamber, causing rapid solvent evaporation, while microencapsulation involves enclosing active ingredients within a protective coating to control release and enhance stability. Spray drying primarily relies on thermal and evaporative processes, whereas microencapsulation uses techniques like coacervation, interfacial polymerization, or liposomal entrapment to form a barrier around core materials. The key difference lies in spray drying producing a dry particulate form quickly, while microencapsulation focuses on encapsulating substances for targeted delivery and protection.

Advantages of Spray Drying

Spray drying offers rapid drying of heat-sensitive materials, preserving bioactive compounds and flavors effectively. Its scalability and cost-efficiency make it ideal for large-scale production in pharmaceuticals, food, and cosmetics industries. Spray drying also ensures uniform particle size distribution, enhancing product solubility and stability compared to other microencapsulation techniques.

Advantages of Microencapsulation

Microencapsulation offers enhanced protection of sensitive ingredients from environmental factors such as oxygen, moisture, and light, ensuring improved stability and extended shelf life compared to spray drying. It enables controlled release and targeted delivery of active compounds, optimizing efficacy in pharmaceuticals, food, and cosmetics. The technique also allows encapsulation of a broader range of materials, including liquids, gases, and solids, which spray drying may not effectively handle.

Limitations and Challenges

Spray drying faces challenges such as thermal degradation of heat-sensitive compounds, limited encapsulation efficiency, and powder stickiness that affects product yield. Microencapsulation, although providing better protection and controlled release, struggles with complex processing techniques, high production costs, and potential particle agglomeration. Both methods require optimization to balance stability, release profiles, and scalability for industrial applications.

Applications in Industry

Spray drying is widely used in the food, pharmaceutical, and chemical industries for converting liquid formulations into dry powders, enhancing product stability and ease of handling. Microencapsulation finds extensive applications in controlled release of active ingredients in sectors such as agriculture for pesticides, pharmaceuticals for drug delivery, and cosmetics for fragrance encapsulation. Both techniques improve product performance, with spray drying favoring bulk powder production and microencapsulation targeting protection and targeted release of sensitive compounds.

Cost and Efficiency Considerations

Spray drying offers a cost-effective and scalable method for encapsulating bioactive compounds, with rapid drying times and high throughput suitable for large-scale production. Microencapsulation through methods like coacervation or liposomal entrapment often incurs higher costs due to complex processes and materials but provides enhanced control over release profiles and protection of sensitive ingredients. Efficiency in spray drying is marked by lower energy consumption per unit product, whereas microencapsulation techniques can result in higher encapsulation efficiency and stability, justifying their premium in specialty applications.

Choosing the Optimal Method

Choosing the optimal method between spray drying and microencapsulation depends on the desired particle size, protection level, and release profile of the encapsulated material. Spray drying offers rapid processing and cost efficiency ideal for heat-stable compounds, while microencapsulation provides enhanced protection and controlled release for sensitive bioactives through specialized coating techniques. Evaluating factors like thermal sensitivity, encapsulation efficiency, and end-use application ensures selection of the most effective technology for powder formulation and product stability.

Spray Drying Infographic

libterm.com

libterm.com