British Standard Whitworth (BSW) is a screw thread standard widely recognized for its distinctive 55-degree thread angle and rounded crests and roots, offering reliable fastening solutions in mechanical engineering. This standard ensures compatibility and interchangeability in fasteners, making it essential for maintaining equipment with historical or legacy components. Explore the rest of the article to understand how BSW threads can be integrated into your projects and their key advantages.

Table of Comparison

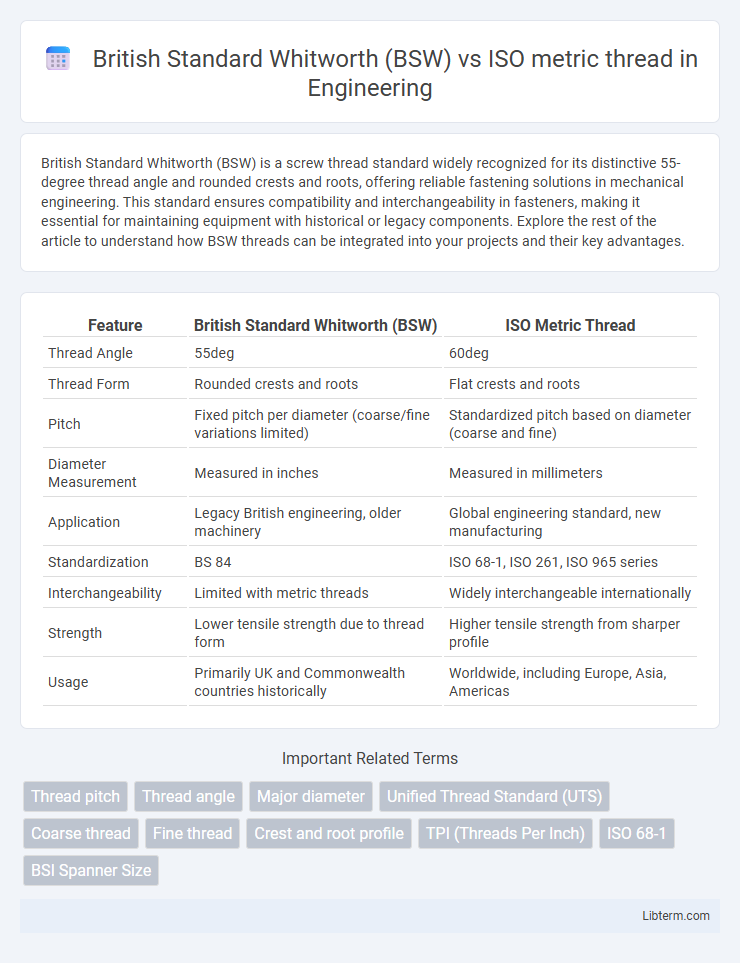

| Feature | British Standard Whitworth (BSW) | ISO Metric Thread |

|---|---|---|

| Thread Angle | 55deg | 60deg |

| Thread Form | Rounded crests and roots | Flat crests and roots |

| Pitch | Fixed pitch per diameter (coarse/fine variations limited) | Standardized pitch based on diameter (coarse and fine) |

| Diameter Measurement | Measured in inches | Measured in millimeters |

| Application | Legacy British engineering, older machinery | Global engineering standard, new manufacturing |

| Standardization | BS 84 | ISO 68-1, ISO 261, ISO 965 series |

| Interchangeability | Limited with metric threads | Widely interchangeable internationally |

| Strength | Lower tensile strength due to thread form | Higher tensile strength from sharper profile |

| Usage | Primarily UK and Commonwealth countries historically | Worldwide, including Europe, Asia, Americas |

Introduction to Thread Standards

British Standard Whitworth (BSW) threads are characterized by a 55-degree thread angle and rounded crests and roots, originally developed in 1841 for engineering applications in the UK. ISO metric threads, standardized by the International Organization for Standardization (ISO), feature a 60-degree thread angle with flat crests and roots, widely adopted globally for modern manufacturing. Both standards define thread pitch, diameter, and form, but ISO metric threads provide greater uniformity in international engineering and industrial contexts.

Historical Background of BSW and ISO Metric Threads

British Standard Whitworth (BSW) threads, introduced by Sir Joseph Whitworth in 1841, were the first standardized thread form, pioneering uniformity in screw threads during the Industrial Revolution. The ISO metric thread, established in 1947 by the International Organization for Standardization (ISO), was designed to replace diverse national standards, promoting global compatibility through a simplified, metric-based profile. The transition from BSW to ISO metric threads marked a shift from imperial measurements to a universally accepted metric system, facilitating international manufacturing and engineering collaboration.

Key Design Differences

British Standard Whitworth (BSW) threads feature a 55-degree thread angle with rounded crests and roots, providing a distinctive profile that reduces stress concentration and enhances fatigue resistance. In contrast, ISO metric threads use a 60-degree thread angle with flattened crest and root profiles, facilitating easier manufacturing and superior compatibility in global fastener applications. The pitch and dimension standards differ, with BSW threads following imperial measurements and ISO metric threads adhering to metric units, influencing interchangeability and tooling requirements.

Material and Application Suitability

British Standard Whitworth (BSW) threads, typically made from high-strength carbon steel or alloy steel, excel in heavy-duty applications requiring robust load-bearing capacity, such as automotive and machinery assemblies. ISO metric threads, produced from a variety of materials including stainless steel and brass, are designed for wide-ranging industrial use with superior corrosion resistance and precision fitting in electronics and aerospace sectors. Material compatibility and application environment dictate the choice, with BSW favored for mechanical robustness and ISO metric preferred for versatility and standardized global interchangeability.

Dimensional Chart Comparison

The British Standard Whitworth (BSW) thread features a 55-degree thread angle with rounded roots and crests, whereas the ISO metric thread utilizes a 60-degree angle with flattened roots and crests, optimizing strength and manufacturing consistency. Dimensional charts highlight BSW's use of pitches measured in threads per inch (TPI) and ISO metric's standardized pitch in millimeters, facilitating global interchangeability. Differences in major diameter, pitch diameter, and minor diameter measurements between BSW and ISO metric threads are critical for engineering applications requiring precise compatibility and mechanical performance.

Compatibility and Interchangeability

British Standard Whitworth (BSW) threads feature a 55-degree thread angle and a rounded profile, whereas ISO metric threads use a 60-degree thread angle with a flattened crest and root. Due to these fundamental differences in thread geometry and pitch standards, BSW and ISO metric threads are not compatible, preventing direct interchangeability between the two systems. Using a bolt and nut from different standards risks poor fit, reduced mechanical strength, and potential thread damage.

Performance and Strength Analysis

British Standard Whitworth (BSW) threads feature a 55-degree thread angle with rounded crests and roots, enhancing stress distribution and fatigue resistance, whereas ISO metric threads have a 60-degree thread angle with flattened crests and roots designed for ease of manufacturing and standardization. Performance-wise, BSW threads tend to exhibit superior shear strength and longevity in high-load, vibration-prone applications due to their shape, while ISO metric threads provide better versatility and compatibility across global engineering standards. Strength analysis reveals BSW's rounded profile leads to reduced stress concentration and improved resistance to stripping, but ISO metric threads benefit from tighter tolerance control, enabling consistent assembly and predictable mechanical behavior.

Global Usage and Industry Adoption

The British Standard Whitworth (BSW) thread, established in the 19th century, remains primarily used in the UK and former British colonies for maintenance and restoration of vintage machinery. In contrast, the ISO metric thread, developed by the International Organization for Standardization, is globally recognized and widely adopted across industries including automotive, aerospace, and manufacturing for new production due to its standardized profile and ease of interoperability. ISO metric threads have become the default choice in international trade and engineering, reflecting a universal standard that simplifies design and component compatibility worldwide.

Pros and Cons of BSW vs ISO Metric Threads

British Standard Whitworth (BSW) threads feature a 55-degree thread angle and coarse pitch, offering strong resistance to shear stress and easy manufacturing with older tooling, but are less precise and incompatible with modern metric systems. ISO metric threads have a 60-degree angle and a standardized pitch, delivering better mechanical performance, international compatibility, and scalability in various applications, though they may require more precise manufacturing processes. Choosing BSW supports legacy British equipment, while ISO metric threads are preferred for global interoperability and modern engineering standards.

Choosing the Right Thread Standard

Selecting the right thread standard between British Standard Whitworth (BSW) and ISO metric threads depends on application requirements, regional compatibility, and tooling availability. BSW threads feature a 55-degree thread angle and are commonly used in vintage British machinery, while ISO metric threads with a 60-degree angle are internationally standardized for general engineering and manufacturing. Ensuring compatibility with existing components and industry norms optimizes assembly efficiency and functional reliability.

British Standard Whitworth (BSW) Infographic

libterm.com

libterm.com