Mobile cranes offer unparalleled flexibility and efficiency for lifting heavy loads across various construction and industrial sites. Their ability to move easily and set up quickly makes them essential for projects requiring rapid repositioning and diverse lifting capabilities. Discover how choosing the right mobile crane can enhance your operations by reading the rest of this article.

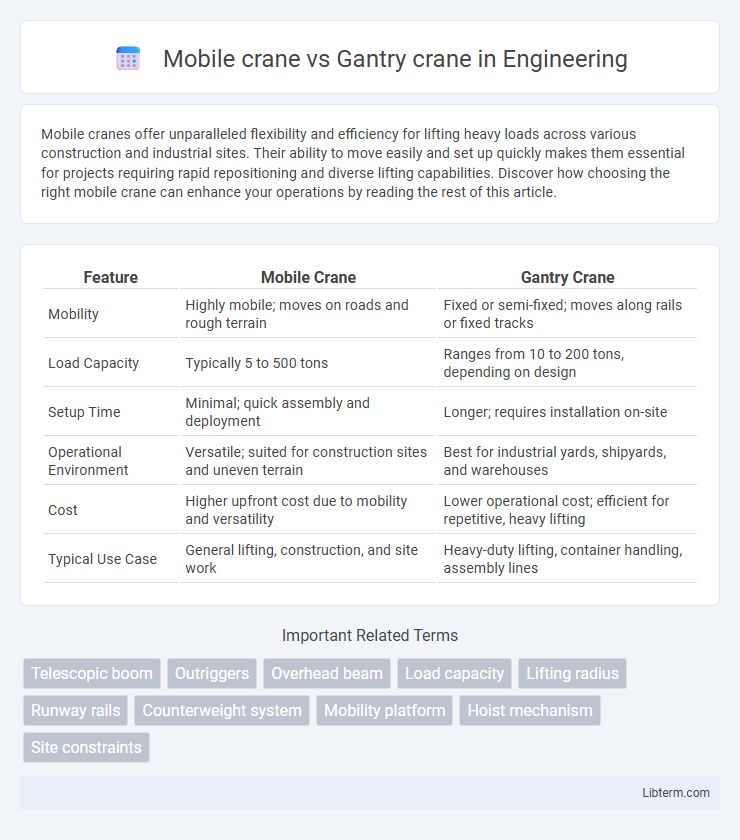

Table of Comparison

| Feature | Mobile Crane | Gantry Crane |

|---|---|---|

| Mobility | Highly mobile; moves on roads and rough terrain | Fixed or semi-fixed; moves along rails or fixed tracks |

| Load Capacity | Typically 5 to 500 tons | Ranges from 10 to 200 tons, depending on design |

| Setup Time | Minimal; quick assembly and deployment | Longer; requires installation on-site |

| Operational Environment | Versatile; suited for construction sites and uneven terrain | Best for industrial yards, shipyards, and warehouses |

| Cost | Higher upfront cost due to mobility and versatility | Lower operational cost; efficient for repetitive, heavy lifting |

| Typical Use Case | General lifting, construction, and site work | Heavy-duty lifting, container handling, assembly lines |

Introduction to Mobile Cranes and Gantry Cranes

Mobile cranes are versatile lifting machines equipped with a telescoping boom mounted on mobile platforms like trucks or crawlers, facilitating easy transportation and rapid setup on construction sites. Gantry cranes consist of a bridge supported by two or more legs that move on fixed rails, primarily used for heavy lifting in shipyards, warehouses, and industrial environments. Both cranes serve distinct purposes, with mobile cranes providing flexibility across various terrains and gantry cranes offering stability and capacity for large-scale, repetitive lifting tasks.

Key Differences Between Mobile and Gantry Cranes

Mobile cranes feature a flexible, wheeled or tracked chassis allowing easy transportation and quick setup across various job sites, making them ideal for short-term projects. Gantry cranes, characterized by their fixed or semi-fixed overhead structure supported by legs on wheels or rails, excel in lifting heavy loads within a defined operational area such as shipyards or warehouses. The primary distinctions lie in mobility--mobile cranes offer superior versatility, while gantry cranes provide increased lifting capacity and stability for repetitive, heavy-duty tasks.

Design and Structural Features

Mobile cranes feature a telescopic boom mounted on a movable carrier, allowing versatile lifting with adjustable length and height, supported by hydraulic systems for stability and maneuverability. Gantry cranes consist of a fixed or semi-fixed framework with a horizontal beam supported by vertical legs, designed for heavy-duty lifting over a fixed area, often equipped with rails for precise movement. The mobile crane's lightweight, compact design contrasts with the gantry crane's robust, large-scale structure optimized for industrial environments and heavy loads.

Mobility and Maneuverability Comparison

Mobile cranes offer superior mobility with their wheeled or tracked chassis, allowing easy transportation across various terrains and quick setup at multiple job sites. Gantry cranes, while highly efficient for lifting heavy loads within fixed areas such as shipyards or warehouses, lack the flexibility to move independently over long distances. The maneuverability of mobile cranes excels in confined or uneven spaces, whereas gantry cranes require pre-established rails or tracks for movement, limiting their operational range.

Load Capacity and Lifting Power

Mobile cranes typically offer load capacities ranging from 10 to 1,200 tons, making them suitable for versatile, on-site lifting tasks with high mobility. Gantry cranes, on the other hand, excel in heavy-duty lifting power, with capacities often exceeding 1,000 tons, optimized for stationary, continuous operations in industrial environments. The choice between mobile and gantry cranes hinges on the required lifting power and load capacity in relation to project mobility and operational context.

Typical Applications and Use Cases

Mobile cranes excel in construction, infrastructure projects, and emergency response due to their versatility and mobility, enabling lifting and moving heavy loads across diverse terrains. Gantry cranes are primarily used in shipyards, warehouses, and manufacturing plants for lifting heavy containers, large machinery, and structural components within fixed or semi-fixed areas. Specific use cases for mobile cranes include bridge construction and utility maintenance, while gantry cranes efficiently handle repetitive lifting tasks in container terminals and assembly lines.

Setup, Installation, and Operational Flexibility

Mobile cranes offer rapid setup and minimal installation, enabling swift deployment across various job sites with high operational flexibility due to their ability to move easily. Gantry cranes require a more extended installation period, often involving track alignment and structural assembly, limiting relocation ease but providing consistent, heavy-duty lifting within fixed areas. The choice between mobile and gantry cranes hinges on project mobility requirements and installation constraints, impacting site efficiency and operational adaptability.

Safety Considerations and Standards

Mobile cranes require stringent adherence to OSHA standards 29 CFR 1926.550, emphasizing proper setup on stable ground and load capacity limits to prevent accidents. Gantry cranes must comply with ANSI B30.17 standards, ensuring structural integrity and regular inspection to avoid structural failures during lifting operations. Both crane types demand certified operator training and routine maintenance checks to mitigate risks and enhance workplace safety.

Cost Analysis: Purchase, Maintenance, and Operation

Mobile cranes typically involve higher initial purchase costs due to their complex hydraulic systems and mobility features, whereas gantry cranes generally have lower upfront expenses as they are fixed and simpler in design. Maintenance costs for mobile cranes tend to be greater because of frequent wear from transportation and complex mechanical parts; gantry cranes require less intensive upkeep but demand regular track and structural inspections. Operational expenses for mobile cranes are elevated by fuel consumption and operator training, while gantry cranes benefit from lower energy use and simpler operation, reflecting a cost-effective option for consistent, heavy lifting tasks.

Choosing the Right Crane for Your Project

Selecting the right crane for your project depends on mobility requirements and load capacity; mobile cranes offer flexibility for various terrains and quick relocation, while gantry cranes provide high lifting power with stability for fixed locations such as shipyards or warehouses. Mobile cranes excel in short-term projects with diverse sites, whereas gantry cranes are ideal for heavy-duty lifting in structured environments. Evaluating site conditions, load weight, and project duration ensures the optimal crane choice for efficient and safe lifting operations.

Mobile crane Infographic

libterm.com

libterm.com