A needle valve provides precise control over fluid flow by allowing small adjustments in flow rate through a tapered needle-shaped plunger. Commonly used in applications requiring accurate regulation of gases or liquids, needle valves ensure smooth and stable operation in sensitive systems. Explore the article to learn how a needle valve can enhance the performance of your fluid control setup.

Table of Comparison

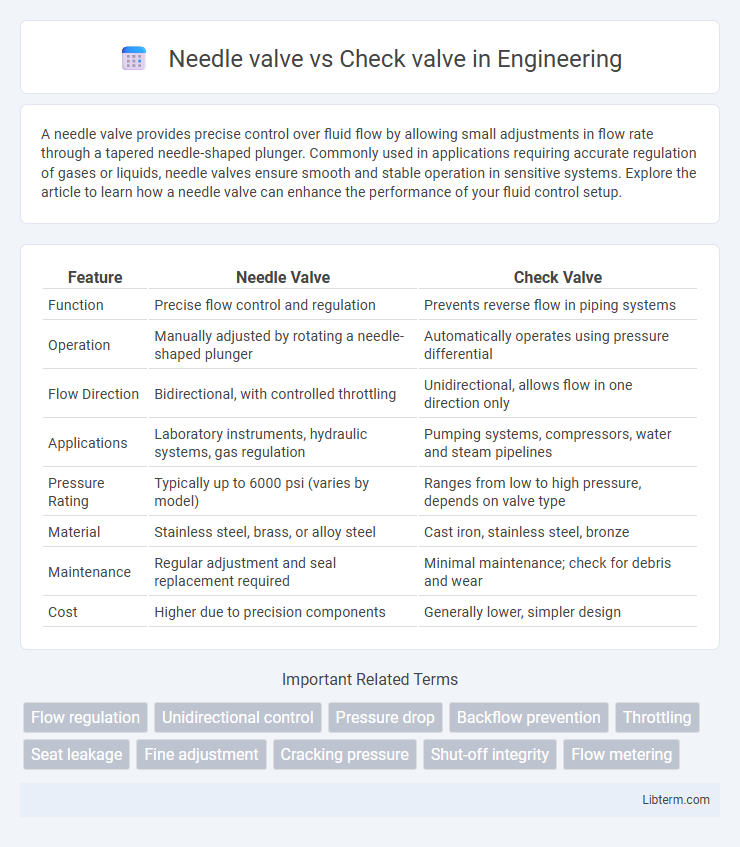

| Feature | Needle Valve | Check Valve |

|---|---|---|

| Function | Precise flow control and regulation | Prevents reverse flow in piping systems |

| Operation | Manually adjusted by rotating a needle-shaped plunger | Automatically operates using pressure differential |

| Flow Direction | Bidirectional, with controlled throttling | Unidirectional, allows flow in one direction only |

| Applications | Laboratory instruments, hydraulic systems, gas regulation | Pumping systems, compressors, water and steam pipelines |

| Pressure Rating | Typically up to 6000 psi (varies by model) | Ranges from low to high pressure, depends on valve type |

| Material | Stainless steel, brass, or alloy steel | Cast iron, stainless steel, bronze |

| Maintenance | Regular adjustment and seal replacement required | Minimal maintenance; check for debris and wear |

| Cost | Higher due to precision components | Generally lower, simpler design |

Introduction to Needle Valves and Check Valves

Needle valves provide precise flow control by allowing fine adjustment of fluid flow in piping systems, featuring a small, tapered needle-like plunger that fits into a seat. Check valves, designed to prevent backflow, automatically allow fluid to flow in one direction while blocking reverse flow, ensuring system protection and maintaining directional consistency. Both valves play crucial roles in fluid management but serve different operational functions based on flow control and prevention requirements.

Key Functions and Applications

Needle valves provide precise flow control by allowing fine adjustment of fluid flow rates, making them ideal for calibration systems and fuel regulation in engines. Check valves prevent backflow and ensure unidirectional fluid movement, crucial for protecting pumps and compressors in pipelines and water systems. Needle valves excel in low-flow, high-pressure environments, while check valves are essential in hydraulic and pneumatic circuits for safety and efficiency.

Design and Mechanism Differences

Needle valves feature a slender, needle-shaped plunger that precisely controls flow rate by adjusting the flow passage size, ideal for fine flow regulation. Check valves employ a one-way mechanism with a disc or ball that automatically prevents backflow, allowing fluid to flow in only one direction without manual intervention. The key design difference lies in the needle valve's manual, adjustable throttling capability versus the check valve's automatic, non-return function.

Flow Control Capabilities

Needle valves provide precise flow control through a fine-threaded stem that adjusts the flow rate incrementally, making them ideal for applications requiring accurate regulation of fluid. Check valves, on the other hand, allow unidirectional flow and prevent backflow but do not offer adjustable flow control, functioning primarily as safety components. The distinct flow control capabilities of needle valves enable fine-tuning in systems, whereas check valves ensure system integrity by maintaining proper flow direction.

Installation Requirements

Needle valves require precise alignment and clean piping due to their fine control mechanism, often installed in instrumentation or flow metering systems where accurate flow regulation is critical. Check valves, designed to prevent backflow, must be installed following flow direction indicators, with sufficient straight pipe length upstream to ensure proper sealing and avoid water hammer effects. Both valve types demand careful consideration of space constraints and material compatibility to ensure optimal performance and durability in their respective applications.

Material and Durability Comparison

Needle valves are typically constructed from stainless steel, brass, or bronze, offering high corrosion resistance and precision control, which ensures durability in high-pressure and high-temperature environments. Check valves are commonly made from cast iron, stainless steel, or PVC, designed to prevent backflow with robust seals and components that withstand varying fluids and pressures, enhancing longevity. The material choice directly impacts durability, with stainless steel providing superior resistance, while plastic materials in check valves suit less demanding applications.

Maintenance and Troubleshooting

Needle valves require regular inspection and cleaning of their fine-threaded stem and seat to prevent clogging and ensure precise flow control, with common maintenance involving lubrication and seal replacement. Check valves demand frequent checking for debris, wear, and spring tension issues to prevent backflow and leakage, with troubleshooting often focused on stuck or noisy valve discs. Both valves benefit from scheduled preventive maintenance to avoid operational failures and extend service life in fluid control systems.

Cost Considerations

Needle valves generally have a higher initial cost due to their precise flow control mechanisms and durable materials suited for fine adjustments. Check valves often cost less upfront because their simpler design primarily prevents backflow without requiring intricate parts. Long-term maintenance expenses might differ, with needle valves requiring more frequent servicing to maintain accuracy, while check valves tend to have lower upkeep costs due to fewer moving components.

Industry-Specific Use Cases

Needle valves provide precise flow control in industries like chemical processing and pharmaceuticals where accurate metering of fluids is critical. Check valves are essential in oil and gas pipelines and water treatment plants to prevent backflow and protect equipment from pressure surges. Both valves enhance system safety and efficiency by addressing specific operational needs unique to fluid dynamics in industrial applications.

Choosing the Right Valve: Needle vs Check

Needle valves offer precise flow control for low flow applications, making them ideal for calibration and fine-tuning systems, while check valves prevent backflow and protect equipment in pipelines by allowing fluid to flow in only one direction. Selecting the right valve depends on whether controlling flow rate or preventing reverse flow is the primary requirement. Consider system pressure, flow sensitivity, and operational safety when choosing between needle or check valves for optimal performance.

Needle valve Infographic

libterm.com

libterm.com