Cross-flow technology enhances heat exchange efficiency by allowing fluid streams to flow perpendicular to each other, optimizing temperature transfer without mixing. This method is widely used in HVAC systems, radiators, and industrial processes to improve energy conservation and system performance. Explore the following article to understand how cross-flow designs can benefit your applications.

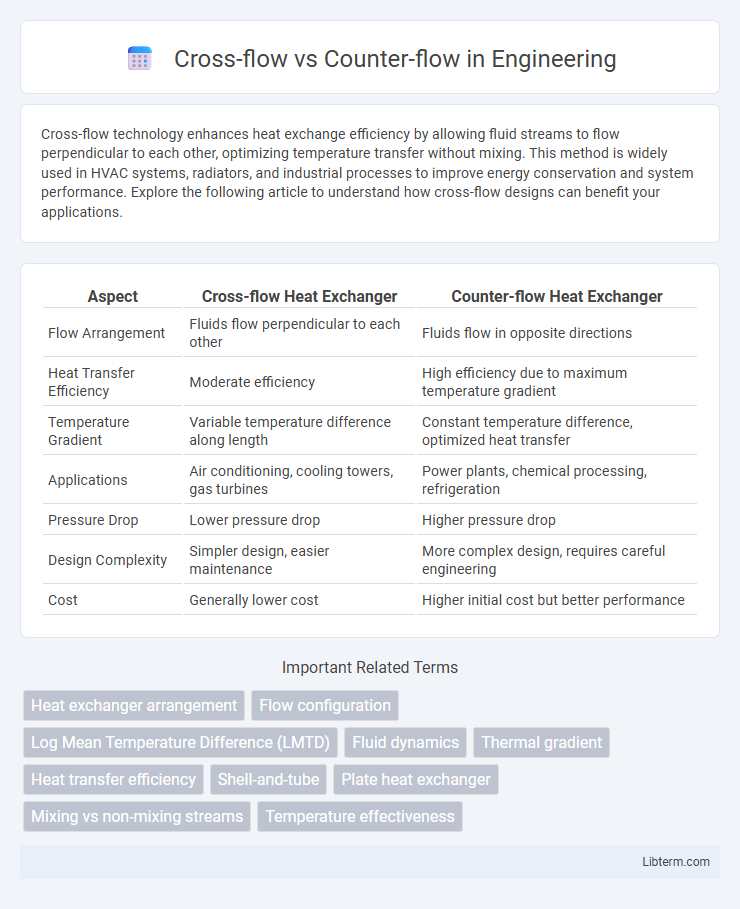

Table of Comparison

| Aspect | Cross-flow Heat Exchanger | Counter-flow Heat Exchanger |

|---|---|---|

| Flow Arrangement | Fluids flow perpendicular to each other | Fluids flow in opposite directions |

| Heat Transfer Efficiency | Moderate efficiency | High efficiency due to maximum temperature gradient |

| Temperature Gradient | Variable temperature difference along length | Constant temperature difference, optimized heat transfer |

| Applications | Air conditioning, cooling towers, gas turbines | Power plants, chemical processing, refrigeration |

| Pressure Drop | Lower pressure drop | Higher pressure drop |

| Design Complexity | Simpler design, easier maintenance | More complex design, requires careful engineering |

| Cost | Generally lower cost | Higher initial cost but better performance |

Introduction to Heat Exchanger Flow Arrangements

Cross-flow heat exchangers feature fluid streams that move perpendicular to each other, enhancing heat transfer through increased turbulence and surface area contact. Counter-flow arrangements align fluid streams in opposite directions, maximizing temperature gradients and improving thermal efficiency. These flow configurations directly impact the heat exchanger's performance, pressure drop, and suitability for specific industrial applications.

Understanding Cross-flow Configuration

Cross-flow heat exchangers feature two fluid streams flowing perpendicular to each other, enhancing heat transfer efficiency by maximizing the temperature difference between fluids at various points along the exchanger. This configuration enables a more uniform temperature gradient, making it ideal for applications requiring moderate heat transfer rates and compact design. Commonly used in air cooling and refrigeration systems, cross-flow exchangers balance performance with space constraints and maintenance ease.

Exploring Counter-flow Configuration

Counter-flow heat exchangers offer superior thermal efficiency by maximizing the temperature gradient between the hot and cold fluids throughout the length of the exchanger. This configuration allows the cold fluid to exit at a temperature closer to the hot fluid's inlet temperature, enhancing heat transfer rates. In contrast to cross-flow designs, counter-flow arrangements maintain a more uniform temperature difference, resulting in improved energy conservation and compact equipment size.

Key Differences Between Cross-flow and Counter-flow

Cross-flow heat exchangers feature fluid streams flowing perpendicular to each other, leading to moderate temperature gradients and efficient heat transfer for applications with differing thermal capacities. Counter-flow heat exchangers have fluid streams flowing in opposite directions, maximizing temperature difference along the exchanger length and achieving higher thermal efficiency. The key difference lies in flow arrangement, where counter-flow enables greater heat recovery and tighter temperature approach compared to the typically simpler design of cross-flow systems.

Thermal Efficiency Comparison

Counter-flow heat exchangers exhibit higher thermal efficiency compared to cross-flow designs due to the greater temperature gradient maintained along the flow path, allowing more effective heat transfer. In counter-flow arrangements, the fluid temperatures move in opposite directions, maximizing the average temperature difference and enhancing energy recovery. Cross-flow heat exchangers generally have lower thermal efficiency because the mixed flow reduces the temperature differential, resulting in less efficient heat exchange performance.

Pressure Drop Considerations

In cross-flow heat exchangers, pressure drop is generally lower due to the perpendicular flow paths of the fluids, which reduce frictional losses compared to counter-flow designs. Counter-flow arrangements often exhibit higher pressure drops because fluids flow in opposite directions along the same path, increasing velocity and turbulence. Careful design optimization is required to balance heat transfer efficiency against pressure drop to minimize pumping costs and maintain system performance.

Typical Applications of Cross-flow Systems

Cross-flow heat exchangers are commonly used in applications such as gas coolers, air conditioning systems, and automotive radiators due to their efficient heat transfer between fluids flowing perpendicular to each other. They offer advantages in situations where fluid flow arrangement and pressure drop control are critical, making them ideal for cooling gases and air streams. Typical industries utilizing cross-flow systems include HVAC, automotive, and power generation sectors where compact design and maintenance ease are necessary.

Common Uses of Counter-flow Systems

Counter-flow systems are widely used in heat exchangers, refrigeration, and engineering processes where efficient temperature gradients are crucial. Industrial applications include power plants, chemical reactors, and HVAC systems, leveraging the enhanced heat transfer capabilities of counter-flow designs. Medical devices and automotive radiators also commonly utilize counter-flow to maximize thermal performance and energy conservation.

Factors Influencing Flow Arrangement Selection

Flow arrangement selection depends on factors such as the temperature profiles required, heat exchanger efficiency, and pressure drop limitations. Cross-flow configurations typically suit applications needing moderate temperature changes and accommodate fluids with significant flow rate differences. Counter-flow arrangements maximize heat transfer efficiency and temperature gradients, favoring processes demanding close temperature approaches and higher thermal performance.

Conclusion: Choosing the Right Flow Type

Counter-flow heat exchangers offer superior thermal efficiency by maintaining a greater temperature gradient between fluids, making them ideal for applications requiring maximum heat transfer. Cross-flow heat exchangers provide flexibility and compact design advantages, suitable for processes with variable flow rates or space constraints. Selecting the right flow type depends on the specific operational goals, space availability, and fluid properties to optimize performance and cost-effectiveness.

Cross-flow Infographic

libterm.com

libterm.com