Induction hardening is a heat treatment process that enhances the surface hardness and wear resistance of steel components through rapid heating and rapid cooling. This technique improves the durability and fatigue strength of parts while maintaining their core toughness, making it ideal for automotive, aerospace, and industrial applications. Explore the article to learn how induction hardening can optimize your manufacturing processes and product performance.

Table of Comparison

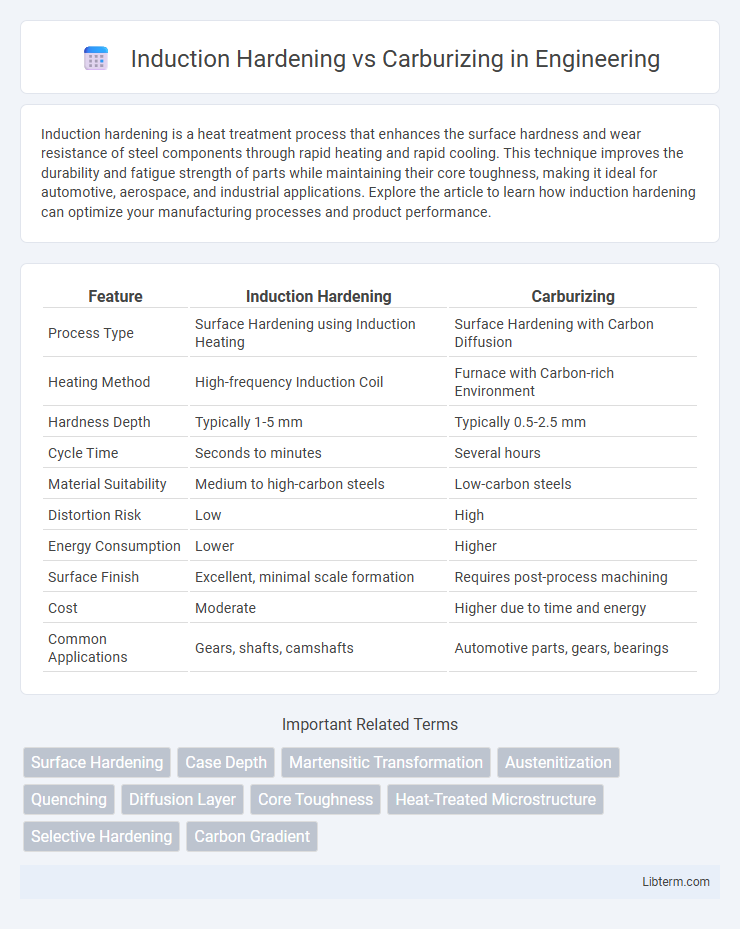

| Feature | Induction Hardening | Carburizing |

|---|---|---|

| Process Type | Surface Hardening using Induction Heating | Surface Hardening with Carbon Diffusion |

| Heating Method | High-frequency Induction Coil | Furnace with Carbon-rich Environment |

| Hardness Depth | Typically 1-5 mm | Typically 0.5-2.5 mm |

| Cycle Time | Seconds to minutes | Several hours |

| Material Suitability | Medium to high-carbon steels | Low-carbon steels |

| Distortion Risk | Low | High |

| Energy Consumption | Lower | Higher |

| Surface Finish | Excellent, minimal scale formation | Requires post-process machining |

| Cost | Moderate | Higher due to time and energy |

| Common Applications | Gears, shafts, camshafts | Automotive parts, gears, bearings |

Introduction to Induction Hardening and Carburizing

Induction hardening and carburizing are two advanced heat treatment processes used to enhance the surface hardness and wear resistance of steel components. Induction hardening rapidly heats the metal surface through electromagnetic induction, followed by immediate quenching, resulting in a hard, wear-resistant surface with minimal distortion. Carburizing introduces carbon into the steel surface at high temperatures in a controlled atmosphere, creating a hardened outer layer while maintaining a softer, tough core, ideal for components requiring high fatigue strength.

Basic Principles of Induction Hardening

Induction hardening uses electromagnetic induction to heat the surface of steel rapidly, followed by immediate quenching, creating a hardened martensitic layer without affecting the core's toughness. This process provides precise control over the hardened depth and minimizes dimensional changes, making it ideal for components requiring wear resistance and fatigue strength. Unlike carburizing, which diffuses carbon into the surface over a longer period, induction hardening alters only the microstructure through thermal transformation.

Fundamental Process of Carburizing

Carburizing is a heat treatment process where steel is heated in a carbon-rich environment, allowing carbon atoms to diffuse into the surface layer, significantly enhancing hardness and wear resistance. This diffusion hardens the case while maintaining a tough core, ideal for components subjected to high surface stresses and fatigue. Unlike induction hardening, which uses rapid heating and quenching, carburizing relies on prolonged exposure to carbon at elevated temperatures to achieve case depth and desired mechanical properties.

Key Differences Between Induction Hardening and Carburizing

Induction hardening rapidly heats the metal surface using electromagnetic induction, creating a hardened layer with precise control over depth and minimal distortion. Carburizing involves diffusing carbon into the metal at high temperatures over hours, producing a deeper hardened layer ideal for wear resistance but with potential dimensional changes. The key differences lie in process time, depth of the hardened layer, and the resulting mechanical properties such as surface hardness and core toughness.

Material Compatibility and Selection Criteria

Induction hardening is best suited for medium to high carbon steels such as AISI 1045 and 4140, providing localized surface hardening with minimal distortion, while carburizing is ideal for low-carbon steels like AISI 1018, allowing deep case hardening through carbon diffusion. Material compatibility depends on the steel's carbon content and alloy composition, with induction hardening favoring steels that harden through martensitic transformation and carburizing requiring low-carbon substrates to form a carbon-rich case. Selection criteria include component geometry, desired case depth, mechanical properties, and cost-effectiveness, where induction hardening offers rapid processing and precision, whereas carburizing provides deeper hardness layers suitable for high-wear resistance.

Surface Hardness and Case Depth Comparison

Induction hardening produces a shallow case depth typically ranging from 0.5 to 6 mm, offering high surface hardness between 55-65 HRC, ideal for localized wear resistance. Carburizing creates a deeper case depth of 0.5 to 2.5 mm or more, with surface hardness commonly between 58-62 HRC, providing improved fatigue strength over larger areas. Both processes enhance surface properties, but induction hardening is preferred for precision hardening, while carburizing suits components requiring uniform case depth and toughness.

Industrial Applications and Use Cases

Induction hardening offers rapid, localized surface hardening ideal for large-scale automotive and heavy machinery components requiring wear resistance without altering core properties. Carburizing suits complex-shaped parts like gears and crankshafts in aerospace and power generation, providing deep case hardening to enhance fatigue strength and durability. Both processes optimize performance and lifespan, with induction hardening favored for precise, energy-efficient treatment and carburizing chosen for heavy-duty, high-stress applications.

Advantages and Limitations of Induction Hardening

Induction hardening offers rapid, localized heating that results in a hardened surface layer with minimal distortion, making it ideal for high-volume production and complex geometries. It provides precise control over hardness depth and does not require post-heat treatment, reducing processing time and costs compared to carburizing. However, induction hardening is limited to ferromagnetic metals, generally treats only accessible surfaces, and achieves shallower case depths than carburizing, which may affect wear resistance in demanding applications.

Benefits and Drawbacks of Carburizing

Carburizing enhances surface hardness and wear resistance by infusing carbon into steel, making it ideal for complex shapes and low-carbon materials. It provides deep case depths and improved fatigue strength but involves longer processing times and potential dimensional distortion. Cost and energy consumption are higher compared to induction hardening, limiting its use in high-volume or time-sensitive applications.

Choosing the Right Heat Treatment Process

Choosing the right heat treatment process between induction hardening and carburizing depends on the component's required surface hardness, depth of hardening, and application. Induction hardening provides rapid, localized hardening with minimal distortion, ideal for parts needing a hard wear-resistant surface without altering the core properties. Carburizing, which diffuses carbon into the surface layer, is suitable for deeper case hardening with improved fatigue resistance on low-carbon steel components.

Induction Hardening Infographic

libterm.com

libterm.com