A notch is a small cut or indentation typically found on the edge of an object or surface, often serving as a functional or decorative feature. In technology, notches are commonly seen on smartphone screens to house cameras or sensors without compromising display area. Discover how notches influence design and usability in modern devices throughout this article.

Table of Comparison

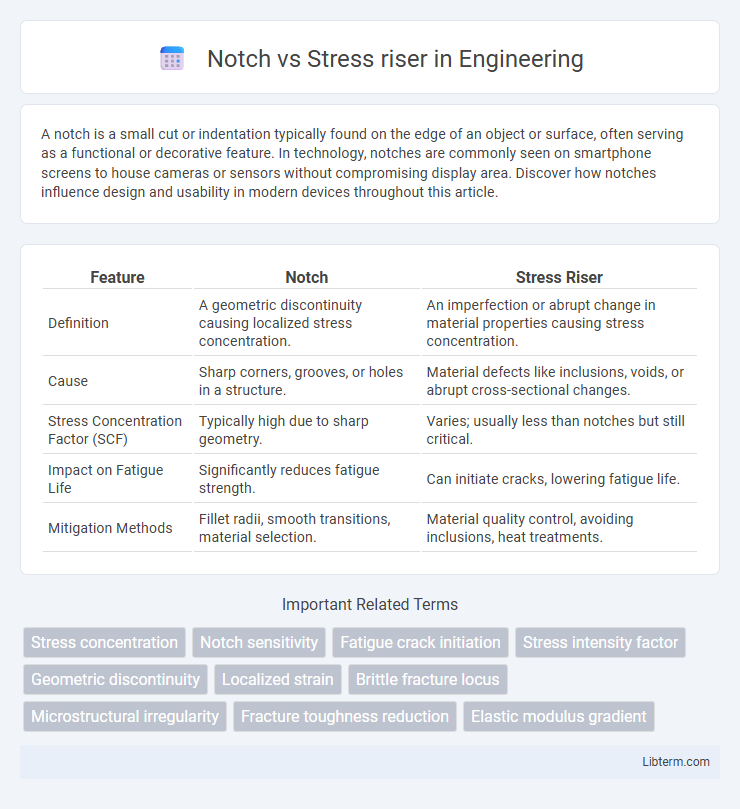

| Feature | Notch | Stress Riser |

|---|---|---|

| Definition | A geometric discontinuity causing localized stress concentration. | An imperfection or abrupt change in material properties causing stress concentration. |

| Cause | Sharp corners, grooves, or holes in a structure. | Material defects like inclusions, voids, or abrupt cross-sectional changes. |

| Stress Concentration Factor (SCF) | Typically high due to sharp geometry. | Varies; usually less than notches but still critical. |

| Impact on Fatigue Life | Significantly reduces fatigue strength. | Can initiate cracks, lowering fatigue life. |

| Mitigation Methods | Fillet radii, smooth transitions, material selection. | Material quality control, avoiding inclusions, heat treatments. |

Introduction to Notch and Stress Riser

A notch is a localized geometric discontinuity or indentation in a material that significantly affects its mechanical behavior by concentrating stress in a small area. Stress risers are specific points within a structure where stress is intensified due to the presence of notches, sharp corners, holes, or cracks, leading to potential failure under lower loads than the material's nominal strength. Understanding the difference between notches and stress risers is essential in material design and structural integrity to prevent unexpected fatigue and fracture.

Definitions: Notch vs Stress Riser

A notch is a deliberate geometric indentation or cut in a material designed to fit components or accommodate assemblies, often resulting in localized stress concentration. A stress riser refers to any irregularity, including notches, holes, grooves, or sharp corners, that causes an increase in localized stress within a material under load. Understanding the distinction between notches as specific designed features and stress risers as general stress-concentrating imperfections is critical for fracture mechanics and material failure analysis.

Causes of Notches and Stress Risers

Notches are caused by geometric discontinuities such as sharp corners, grooves, or holes that create localized reductions in cross-sectional area, leading to stress concentration. Stress risers arise from microscopic defects like cracks, inclusions, or material inconsistencies within a structure that amplify stress at specific points. Both notches and stress risers increase the likelihood of fatigue failure by intensifying stress in small regions, but their origins differ between macroscopic design features and microscopic material flaws.

Mechanical Effects on Materials

Notch introduces localized geometric discontinuities that concentrate stress, significantly reducing the fatigue strength of materials by promoting crack initiation. Stress risers amplify tensile stresses at specific points, exacerbating the risk of material failure under cyclic loading conditions. The interaction between notch geometry and stress risers critically influences the mechanical behavior, often leading to premature fracture and reduced durability in structural components.

Differences in Failure Mechanisms

Notch failure occurs due to localized stress concentration at geometric discontinuities, leading to crack initiation and propagation under cyclic loading. In contrast, stress riser failure results from abrupt changes in material or structural properties that amplify stress beyond design limits, causing premature material yielding or fracture. The primary difference lies in notches being physical indentations that concentrate stress, while stress risers are broader stress amplification effects from material heterogeneities or design flaws.

Impact on Fatigue Life

Notches create geometric discontinuities that concentrate stress locally, significantly reducing fatigue life by facilitating crack initiation under cyclic loading. Stress risers, often caused by surface imperfections or abrupt changes in material properties, amplify stress and accelerate micro-crack formation, thereby decreasing the number of cycles to failure. Both notches and stress risers act as focal points for stress concentration, but notches typically produce more pronounced reductions in fatigue life due to their defined shape and size.

Design Considerations for Engineers

Engineers must consider the impact of notch design on stress concentration to prevent premature material failure in structural components. Optimizing notch geometry by minimizing sharp corners and gradually transitioning cross-sectional areas reduces stress risers and enhances fatigue life. Material selection and advanced simulation tools are crucial for predicting and mitigating notch-induced stress concentrations in critical applications.

Methods to Minimize Notches and Stress Risers

Methods to minimize notches and stress risers include using smooth transitions with radii instead of sharp corners in design to reduce localized stress concentrations. Applying surface treatments such as shot peening and polishing helps to improve fatigue life by eliminating micro-cracks and surface irregularities. Careful material selection and precise machining processes further decrease the risk of stress risers, enhancing overall structural integrity and durability.

Case Studies and Real-World Examples

Case studies reveal how notches, such as geometric discontinuities in metal components, act as stress risers that concentrate stress and cause crack initiation. In aerospace engineering, fatigue failures often originate at notch-induced stress risers, demonstrated by the investigation of aircraft wing cracks linked to rivet holes. Real-world examples from bridge inspections also highlight stress riser effects at weld toes, where small notches accelerate corrosion fatigue and structural degradation.

Conclusion: Best Practices for Structural Integrity

Optimizing structural integrity requires minimizing notch effects and stress risers through precise geometric design and material selection to prevent localized stress concentrations. Employing smooth transitions, fillets, and consistent cross-sections reduces the likelihood of crack initiation and extending fatigue life. Regular inspection and advanced computational simulations support early detection and mitigation, ensuring long-term durability and safety in engineering applications.

Notch Infographic

libterm.com

libterm.com