Toughness measures a material's ability to absorb energy and resist fracture under stress, combining strength and ductility in a critical performance metric. Understanding toughness is essential for selecting materials in applications requiring durability and impact resistance to prevent catastrophic failures. Explore the rest of this article to learn how toughness influences material choice and practical engineering designs.

Table of Comparison

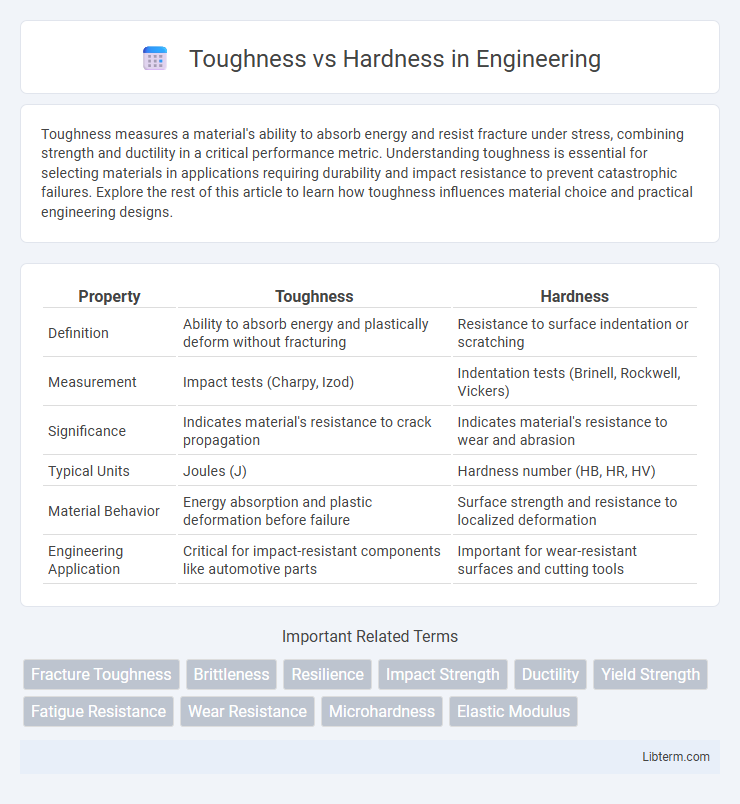

| Property | Toughness | Hardness |

|---|---|---|

| Definition | Ability to absorb energy and plastically deform without fracturing | Resistance to surface indentation or scratching |

| Measurement | Impact tests (Charpy, Izod) | Indentation tests (Brinell, Rockwell, Vickers) |

| Significance | Indicates material's resistance to crack propagation | Indicates material's resistance to wear and abrasion |

| Typical Units | Joules (J) | Hardness number (HB, HR, HV) |

| Material Behavior | Energy absorption and plastic deformation before failure | Surface strength and resistance to localized deformation |

| Engineering Application | Critical for impact-resistant components like automotive parts | Important for wear-resistant surfaces and cutting tools |

Understanding Toughness and Hardness

Toughness measures a material's ability to absorb energy and deform plastically before fracturing, reflecting its resistance to impact and shock. Hardness quantifies a material's resistance to permanent surface indentation or scratching, indicating surface durability. Understanding these properties enables engineers to select materials that balance resistance to wear and impact in diverse applications.

Defining Toughness in Materials

Toughness in materials is defined as the ability to absorb energy and plastically deform without fracturing, reflecting resistance to impact and sudden forces. It is quantitatively measured by the area under the stress-strain curve during a tensile test, indicating the material's capacity to endure both strength and ductility. Unlike hardness, which assesses surface resistance to indentation or scratching, toughness emphasizes a material's overall energy absorption before failure.

What is Hardness?

Hardness refers to a material's resistance to permanent surface deformation or scratching, often measured using tests like the Mohs scale, Rockwell, or Vickers hardness tests. It quantifies how well a material withstands localized plastic deformation under an applied force. Hardness is critical in applications requiring wear resistance and durability, such as cutting tools, coatings, and abrasion-resistant surfaces.

Key Differences Between Toughness and Hardness

Toughness measures a material's ability to absorb energy and deform plastically before fracturing, while hardness quantifies resistance to surface indentation or scratching. Toughness is often evaluated using impact tests such as the Charpy or Izod tests, whereas hardness is assessed with methods like Mohs, Rockwell, or Vickers scales. Unlike hardness, which primarily indicates surface durability, toughness reflects overall material durability by combining strength and ductility.

Applications of Tough Materials

Tough materials are essential in applications requiring resistance to impact and fracture, such as automotive components, aerospace structures, and protective gear. These materials absorb energy and deform plastically before failure, enhancing safety and durability in dynamic environments. Industries prioritize toughness in manufacturing equipment, construction materials, and military armor to ensure structural integrity under extreme conditions.

Where Hardness Matters Most

Hardness is crucial in applications involving surface wear resistance, such as cutting tools, bearings, and molds, where materials must resist scratching, abrasion, and indentation. It determines a material's ability to withstand localized plastic deformation under mechanical stress, ensuring durability and longevity in high-contact environments. Industries like automotive manufacturing, aerospace, and construction heavily rely on hardness to maintain component integrity under harsh operating conditions.

Testing Methods: Measuring Toughness vs Hardness

Toughness is measured using impact toughness tests such as Charpy or Izod, which evaluate a material's ability to absorb energy and resist fracture under sudden loads. Hardness testing methods like Rockwell, Brinell, and Vickers quantify resistance to surface indentation and scratching by applying a controlled force with a standardized indenter. These testing techniques provide complementary data, where toughness assesses energy absorption capacity and hardness indicates surface wear resistance.

Influence of Composition on Toughness and Hardness

The influence of composition on toughness and hardness is critical, with alloying elements such as carbon, manganese, and chromium playing key roles. Increased carbon content generally enhances hardness by promoting the formation of martensite but can reduce toughness by making the material more brittle. Elements like nickel improve toughness by increasing ductility, while chromium and molybdenum contribute to both hardness and toughness by refining grain structure and enhancing resistance to wear and impact.

Toughness and Hardness in Everyday Objects

Toughness measures a material's ability to absorb energy and plastically deform without fracturing, making it crucial in items like car bumpers and phone cases that need to withstand impact without breaking. Hardness refers to a material's resistance to surface deformation and scratching, commonly seen in knife blades and smartphone screens that must maintain a sharp edge or clear surface. Understanding the balance between toughness and hardness helps manufacturers design everyday objects that are both durable and resistant to wear.

Choosing Between Toughness and Hardness for Engineering Design

Choosing between toughness and hardness in engineering design depends on the specific application requirements; toughness measures a material's ability to absorb energy and resist fracture under impact, while hardness indicates resistance to surface deformation and wear. Components subjected to dynamic loads or shock benefit from materials with high toughness to prevent brittle failure, whereas parts experiencing abrasive conditions or surface contact require high hardness to maintain dimensional integrity. Balancing these properties often involves selecting alloys or composites that optimize impact resistance without compromising surface durability, ensuring reliability and longevity of engineering components.

Toughness Infographic

libterm.com

libterm.com