An FTA (Free Trade Agreement) eliminates tariffs and trade barriers between member countries, boosting economic growth and market access. It enhances your business opportunities by enabling smoother cross-border transactions and competitive pricing. Discover how FTAs can transform your trade strategies in the rest of this article.

Table of Comparison

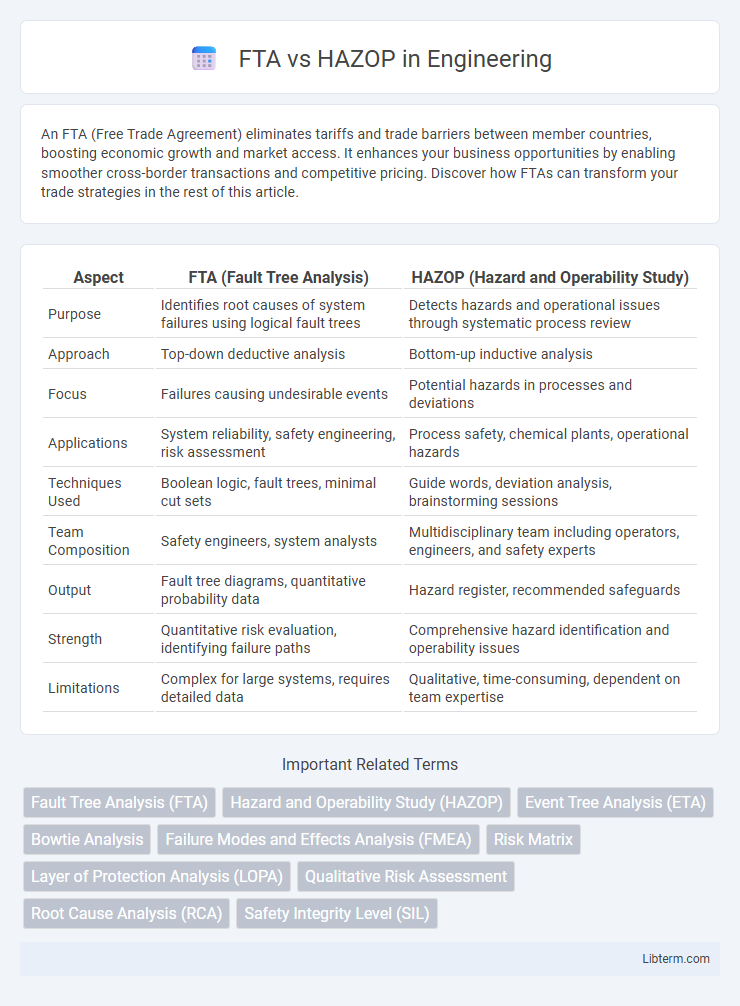

| Aspect | FTA (Fault Tree Analysis) | HAZOP (Hazard and Operability Study) |

|---|---|---|

| Purpose | Identifies root causes of system failures using logical fault trees | Detects hazards and operational issues through systematic process review |

| Approach | Top-down deductive analysis | Bottom-up inductive analysis |

| Focus | Failures causing undesirable events | Potential hazards in processes and deviations |

| Applications | System reliability, safety engineering, risk assessment | Process safety, chemical plants, operational hazards |

| Techniques Used | Boolean logic, fault trees, minimal cut sets | Guide words, deviation analysis, brainstorming sessions |

| Team Composition | Safety engineers, system analysts | Multidisciplinary team including operators, engineers, and safety experts |

| Output | Fault tree diagrams, quantitative probability data | Hazard register, recommended safeguards |

| Strength | Quantitative risk evaluation, identifying failure paths | Comprehensive hazard identification and operability issues |

| Limitations | Complex for large systems, requires detailed data | Qualitative, time-consuming, dependent on team expertise |

Introduction to FTA and HAZOP

Fault Tree Analysis (FTA) systematically identifies the root causes of system failures by using a top-down, deductive approach with Boolean logic. Hazard and Operability Study (HAZOP) employs a structured, qualitative technique to examine potential hazards and operational issues through guidewords and team brainstorming. Both methods enhance safety and reliability by analyzing failures and risks within complex industrial processes.

Defining Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a systematic, top-down approach used to identify and analyze the potential causes of system failures and hazards. It visually represents the logical relationships between various faults and their cumulative effect on system safety, enabling engineers to prioritize risk mitigation strategies. FTA is particularly effective in quantifying the probability of complex system failures by examining fault combinations through Boolean logic.

Defining Hazard and Operability Study (HAZOP)

Hazard and Operability Study (HAZOP) is a structured and systematic technique used to identify potential hazards and operability problems in industrial processes by analyzing deviations from design intentions. Unlike Fault Tree Analysis (FTA) which focuses on the logical relationship of faults leading to system failures, HAZOP emphasizes detailed examination of process parameters and guide words to uncover causes of deviations and their consequences. HAZOP's methodical approach helps improve safety and operational reliability by thoroughly assessing possible risks and ensuring early detection of issues in complex systems.

Key Objectives of FTA

Fault Tree Analysis (FTA) aims to systematically identify the root causes of system failures through a top-down, deductive approach, breaking down complex failure events into basic faults and their logical relationships. The primary objective of FTA is to quantify the probability of system failures and prioritize risk factors for effective mitigation strategies. This method enhances reliability engineering by highlighting critical failure paths and supporting decision-making for safety improvements.

Key Objectives of HAZOP

HAZOP (Hazard and Operability Study) primarily aims to identify and evaluate potential hazards and operability problems within industrial processes by systematically examining process deviations through guide words. Unlike FTA (Fault Tree Analysis), which focuses on tracing the root causes of system failures, HAZOP emphasizes preventing hazards by analyzing process parameters and their impact on safety and performance. Key objectives of HAZOP include improving process safety, ensuring compliance with regulatory standards, and enhancing operational reliability by detecting design weaknesses early in the project lifecycle.

Methodological Differences: FTA vs HAZOP

Fault Tree Analysis (FTA) employs a top-down, deductive approach to identify root causes of system failures by analyzing logical relationships between events, while Hazard and Operability Study (HAZOP) uses a bottom-up, inductive method focusing on process deviations and their potential hazards. FTA represents failures using Boolean logic to map cause-effect chains, whereas HAZOP relies on guide words to systematically examine process parameters for deviations. The methodological difference centers on FTA's failure-centric, event-driven structure versus HAZOP's emphasis on process conditions and operability through qualitative brainstorming.

Application Areas and Industry Use

FTA (Fault Tree Analysis) is widely applied in aerospace, nuclear power, and automotive industries for identifying potential causes of system failures and assessing risk hierarchically. HAZOP (Hazard and Operability Study) is extensively used in chemical processing, oil and gas, and pharmaceuticals to systematically evaluate process deviations and operational hazards. Both techniques complement safety management by addressing different phases: FTA focuses on failure cause analysis, while HAZOP emphasizes process safety and operability in complex systems.

Strengths and Limitations of FTA

Fault Tree Analysis (FTA) excels in systematically identifying the root causes of complex system failures through a top-down, deductive approach, offering clear visual representation of failure logic. Its strength lies in quantifying failure probabilities, aiding in risk assessment and decision-making processes for safety-critical systems. However, FTA can be time-consuming, relies heavily on complete and accurate data, and may not effectively capture dynamic interactions or human factors compared to more iterative methods like HAZOP.

Strengths and Limitations of HAZOP

HAZOP excels in systematically identifying potential hazards and operability problems through structured brainstorming and guide-word techniques, making it highly effective in process industries with complex chemical reactions. Its strengths include thorough qualitative analysis and the involvement of multidisciplinary teams, which enhances hazard recognition accuracy, though it can be time-consuming and less effective for systems lacking detailed process knowledge. Limitations of HAZOP involve difficulty in quantifying risk levels and dependency on team expertise, which may lead to inconsistent results compared to more quantitative methods like Fault Tree Analysis (FTA).

Choosing Between FTA and HAZOP: Factors to Consider

Choosing between Fault Tree Analysis (FTA) and Hazard and Operability Study (HAZOP) depends on the complexity and nature of the system under evaluation. FTA is ideal for pinpointing root causes in systems with known failure modes, emphasizing logical relationships, while HAZOP excels in identifying potential deviations and operability issues in process systems through detailed guide-word analysis. Consider factors such as project phase, system complexity, data availability, and specific safety or reliability goals when selecting the most effective methodology.

FTA Infographic

libterm.com

libterm.com