A condenser plays a crucial role in various industrial and HVAC systems by efficiently converting vapor into liquid through heat exchange, enhancing energy conservation and system performance. Its design and choice impact the overall efficiency, making it essential to select the right type for your specific application. Explore the rest of this article to understand how condensers work and how to optimize their use in your system.

Table of Comparison

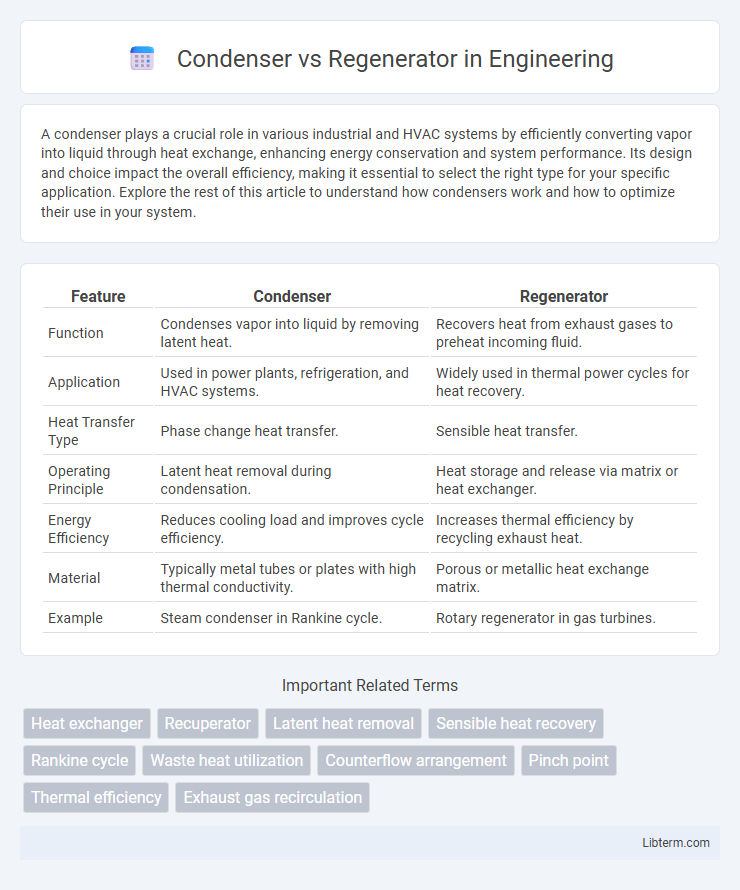

| Feature | Condenser | Regenerator |

|---|---|---|

| Function | Condenses vapor into liquid by removing latent heat. | Recovers heat from exhaust gases to preheat incoming fluid. |

| Application | Used in power plants, refrigeration, and HVAC systems. | Widely used in thermal power cycles for heat recovery. |

| Heat Transfer Type | Phase change heat transfer. | Sensible heat transfer. |

| Operating Principle | Latent heat removal during condensation. | Heat storage and release via matrix or heat exchanger. |

| Energy Efficiency | Reduces cooling load and improves cycle efficiency. | Increases thermal efficiency by recycling exhaust heat. |

| Material | Typically metal tubes or plates with high thermal conductivity. | Porous or metallic heat exchange matrix. |

| Example | Steam condenser in Rankine cycle. | Rotary regenerator in gas turbines. |

Overview of Condenser and Regenerator

A condenser is a heat exchanger that cools and condenses vapor into liquid by removing latent heat, commonly used in power plants and refrigeration systems to improve efficiency. A regenerator is a heat recovery device that temporarily stores heat from hot fluids and transfers it back to incoming cold fluids, enhancing energy conservation in thermal cycles. Both components optimize energy use but serve distinct functions in managing heat transfer within industrial and mechanical processes.

Key Functions and Applications

A condenser primarily functions to convert vapor into liquid by removing heat, playing a crucial role in power plants and refrigeration systems to improve efficiency and energy recovery. A regenerator captures waste heat from exhaust gases to preheat incoming fluid, widely applied in industrial furnaces and gas turbines to enhance thermal efficiency. Both devices optimize energy use but serve different stages within thermal cycles; condensers handle phase change heat transfer, while regenerators focus on heat recovery and reuse.

Working Principles Explained

A condenser operates by transferring heat from a vapor to a cooling medium, causing the vapor to condense into a liquid through latent heat removal. In contrast, a regenerator cyclically stores heat from a hot fluid in a thermal storage medium and then transfers that heat to a cooler fluid, enabling energy recovery and reuse. These working principles highlight the condenser's role in phase change and cooling, while the regenerator emphasizes heat exchange and thermal energy conservation.

Design Differences

Condensers and regenerators both manage heat transfer but differ significantly in design and operation. Condensers are designed as heat exchangers that cool vapor into liquid phase using a cooling medium, typically featuring shell-and-tube or plate configurations optimized for phase change efficiency. Regenerators incorporate a thermal storage medium, such as ceramic or metal matrix, to cyclically absorb and release heat, emphasizing transient heat transfer and periodic airflow reversal for energy recovery.

Performance Comparison

A condenser efficiently removes heat by converting vapor into liquid, maintaining system pressure and improving overall thermal efficiency, especially in power plants and refrigeration cycles. Regenerators, used predominantly in gas turbines and heat recovery systems, store and transfer heat between fluid streams, reducing fuel consumption and enhancing cycle efficiency by reclaiming waste heat. Performance comparison highlights condensers excel in phase change heat transfer for latent heat removal, while regenerators optimize sensible heat recovery, with both critical for maximizing energy efficiency in thermal systems.

Efficiency and Energy Considerations

Condensers typically achieve high thermal efficiency by transferring latent heat from vapor to a cooling medium, minimizing energy loss during phase change processes. Regenerators enhance energy efficiency by temporarily storing heat from exhaust gases and reusing it to preheat incoming fluids, reducing fuel consumption. The choice between condensers and regenerators depends on system design, with regenerators often preferred in applications requiring heat recovery for improved overall energy utilization.

Common Uses in Industry

Condensers are widely used in power plants, chemical processing, and HVAC systems to convert vapor into liquid, enhancing energy efficiency and facilitating heat recovery. Regenerators find common application in glass manufacturing, metal processing, and industrial furnaces, where they capture and reuse heat from exhaust gases to improve fuel efficiency. Both devices play crucial roles in thermal management, optimizing energy consumption across various industrial processes.

Advantages and Disadvantages

A condenser efficiently converts vapor into liquid by removing latent heat, offering advantages such as high thermal efficiency and compact design, but it can struggle with fouling and requires a continuous cooling medium. Regenerators store heat temporarily and transfer it between fluid streams, enhancing energy recovery and reducing fuel consumption, though they often have complex designs and higher maintenance demands. While condensers excel in simple phase change processes, regenerators are better suited for cyclical heat exchange in applications like gas turbines.

Maintenance Requirements

Condensers require regular inspection to prevent fouling and corrosion, ensuring efficient heat transfer and prolonged operational life. Regenerators demand frequent cleaning to remove particulate buildup and periodic evaluation of heat exchange surfaces to maintain optimal thermal recovery. Both systems benefit from scheduled maintenance to avoid performance degradation and costly downtime.

Choosing the Right Option

Selecting between a condenser and a regenerator depends on the specific thermal management needs and efficiency goals of the system. Condensers excel in systems requiring effective phase change heat transfer for cooling or condensation, while regenerators are optimal for recovering and reusing thermal energy in cyclic processes, enhancing overall energy efficiency. Evaluating factors such as operational temperature ranges, heat recovery requirements, and system integration constraints ensures choosing the right heat exchanger type to maximize performance and reduce energy consumption.

Condenser Infographic

libterm.com

libterm.com