Submerged arc welding is a highly efficient process that uses a continuously fed consumable electrode and a blanket of granular flux to protect the weld zone from atmospheric contamination. This method provides deep weld penetration, exceptional mechanical properties, and is widely used in heavy fabrication industries. Explore the rest of the article to discover how submerged arc welding can enhance your welding projects.

Table of Comparison

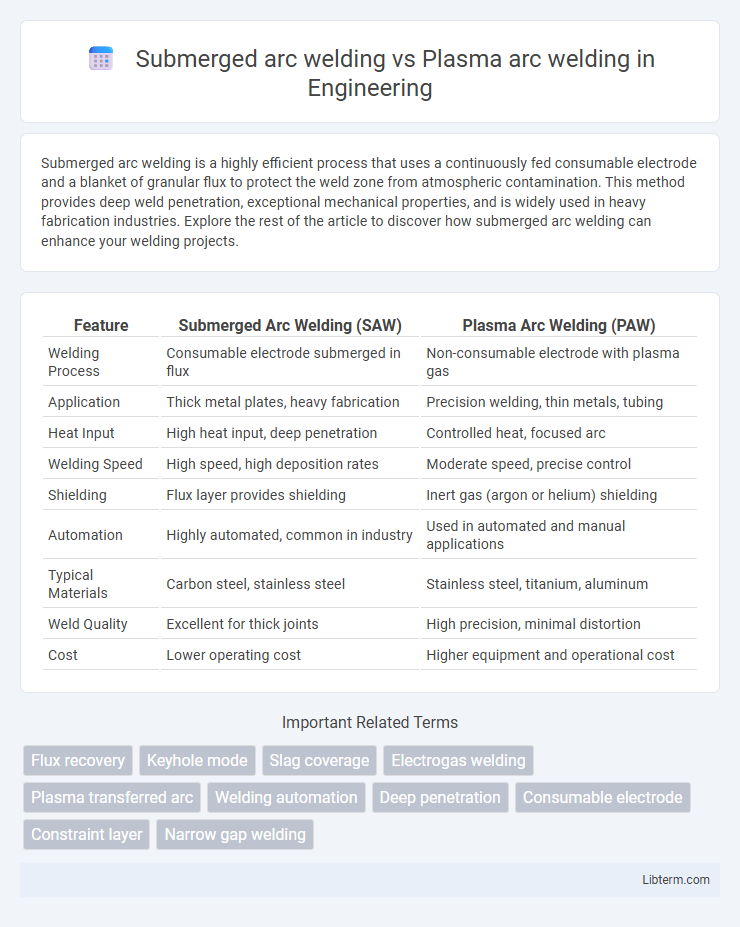

| Feature | Submerged Arc Welding (SAW) | Plasma Arc Welding (PAW) |

|---|---|---|

| Welding Process | Consumable electrode submerged in flux | Non-consumable electrode with plasma gas |

| Application | Thick metal plates, heavy fabrication | Precision welding, thin metals, tubing |

| Heat Input | High heat input, deep penetration | Controlled heat, focused arc |

| Welding Speed | High speed, high deposition rates | Moderate speed, precise control |

| Shielding | Flux layer provides shielding | Inert gas (argon or helium) shielding |

| Automation | Highly automated, common in industry | Used in automated and manual applications |

| Typical Materials | Carbon steel, stainless steel | Stainless steel, titanium, aluminum |

| Weld Quality | Excellent for thick joints | High precision, minimal distortion |

| Cost | Lower operating cost | Higher equipment and operational cost |

Introduction to Submerged Arc Welding and Plasma Arc Welding

Submerged Arc Welding (SAW) utilizes a continuously fed consumable electrode and a granular flux to create high-quality, deep welds with excellent mechanical properties, primarily in thick steel plates for heavy industrial applications. Plasma Arc Welding (PAW) employs a constricted plasma arc to achieve precise, high-temperature welds with superior control over heat input, suitable for thin materials and intricate joints across aerospace and electronic industries. Both processes offer distinct advantages in welding efficiency, penetration, and application range, making them integral in modern manufacturing and fabrication tasks.

Fundamental Principles of Each Welding Process

Submerged arc welding (SAW) operates by creating an arc between a continuously fed electrode and the workpiece beneath a layer of flux, which melts to form a protective slag and ensures deep weld penetration. Plasma arc welding (PAW) utilizes a plasma torch to generate a highly concentrated arc plasma jet that ionizes gas and melts the base metal with precise control and minimal heat-affected zone. The fundamental principle of SAW is flux-mediated arc stabilization and weld pool protection, while PAW relies on plasma jet constriction and high energy density for precise and controlled welding.

Equipment and Setup Comparison

Submerged arc welding (SAW) utilizes a granular flux to protect the weld zone, requiring a heavy-duty wire feeder, flux hopper, and a power source capable of high currents, whereas plasma arc welding (PAW) involves a plasma torch with a fine tungsten electrode and a precise gas delivery system for shielding and plasma formation. SAW equipment is bulkier and designed for long, continuous welds in heavy materials, whereas PAW setups are more compact, allowing for detailed, high-precision welding tasks. The setup time and complexity for plasma arc welding are generally higher due to the need for gas flow control and precise torch positioning compared to the relatively straightforward SAW flux and wire management system.

Material Compatibility and Thickness Range

Submerged arc welding (SAW) excels in welding thick carbon steel and low alloy materials, typically ranging from 3 mm to over 50 mm, offering deep penetration and high deposition rates suitable for heavy fabrication. Plasma arc welding (PAW) supports welding a broader variety of metals, including stainless steel, aluminum, and titanium, with precise control ideal for thinner materials generally between 0.2 mm and 20 mm. The material compatibility of PAW makes it preferable for specialized applications requiring fine weld quality on thin sections, while SAW dominates in high-volume production of thick steel components.

Welding Speed and Efficiency

Submerged arc welding (SAW) offers higher welding speed due to its continuous wire feed and deep penetration capabilities, making it ideal for thick materials and long welds. Plasma arc welding (PAW) provides precise control with faster travel speeds on thinner materials, enhancing efficiency in detailed or complex welds. SAW generally achieves greater deposition rates, contributing to overall higher welding efficiency in heavy fabrication compared to PAW.

Weld Quality and Appearance

Submerged arc welding (SAW) produces deep, high-quality welds with excellent penetration and minimal spatter, resulting in smooth, uniform weld beads ideal for thick materials. Plasma arc welding (PAW) offers precise control and produces clean, visually appealing welds with narrow, consistent beads and superior weld clarity, suitable for thin materials and detailed work. Weld quality in SAW excels in structural strength and toughness, while PAW provides enhanced surface finish and minimal distortion.

Heat Input and Penetration Characteristics

Submerged arc welding (SAW) delivers higher heat input due to its continuous and high-amperage arc, enabling deep penetration suited for thick materials. Plasma arc welding (PAW) offers a more concentrated arc with lower heat input, resulting in precise, controlled penetration ideal for thin or intricate components. The controlled heat input in PAW minimizes distortion and heat-affected zone size, while SAW's intense heat promotes faster welding speed and greater material fusion depth.

Safety Considerations in Both Methods

Submerged arc welding (SAW) offers enhanced safety by minimizing arc exposure and containing fumes under a granular flux layer, significantly reducing operator risk from radiation and spatter. Plasma arc welding (PAW), while providing precise control and lower heat input, requires strict protective measures against intense ultraviolet radiation and high-velocity plasma jets that can cause serious burns or eye injury. Both processes demand adequate ventilation systems and personal protective equipment to safeguard operators from hazardous fumes and arc flash hazards.

Typical Applications and Industry Usage

Submerged arc welding (SAW) is predominantly used in heavy industries like shipbuilding, structural steel fabrication, and pipeline construction due to its high deposition rates and deep weld penetration. Plasma arc welding (PAW) finds extensive application in aerospace, medical device manufacturing, and precision engineering, where its superior control and weld quality on thin materials are critical. Both technologies serve distinct industry needs--SAW excels in high-volume, thick material welding, while PAW is preferred for delicate, high-precision weld requirements.

Cost Implications and Economic Analysis

Submerged arc welding (SAW) generally offers lower operational costs due to higher deposition rates and less consumable usage compared to plasma arc welding (PAW), which tends to incur higher equipment and maintenance expenses. SAW's efficiency in heavy industrial applications translates to reduced labor and energy costs, making it economically favorable for large-scale production. Conversely, PAW provides precision and automation advantages that may justify its higher upfront costs in specialized, high-quality welding projects.

Submerged arc welding Infographic

libterm.com

libterm.com