Acme threads provide superior strength and durability compared to standard screw threads, making them ideal for heavy-duty applications such as lead screws in machinery and jacks. Their trapezoidal thread profile reduces friction and wear, enhancing efficiency and lifespan in mechanical systems. Explore the full article to understand how Acme threads can optimize your equipment's performance.

Table of Comparison

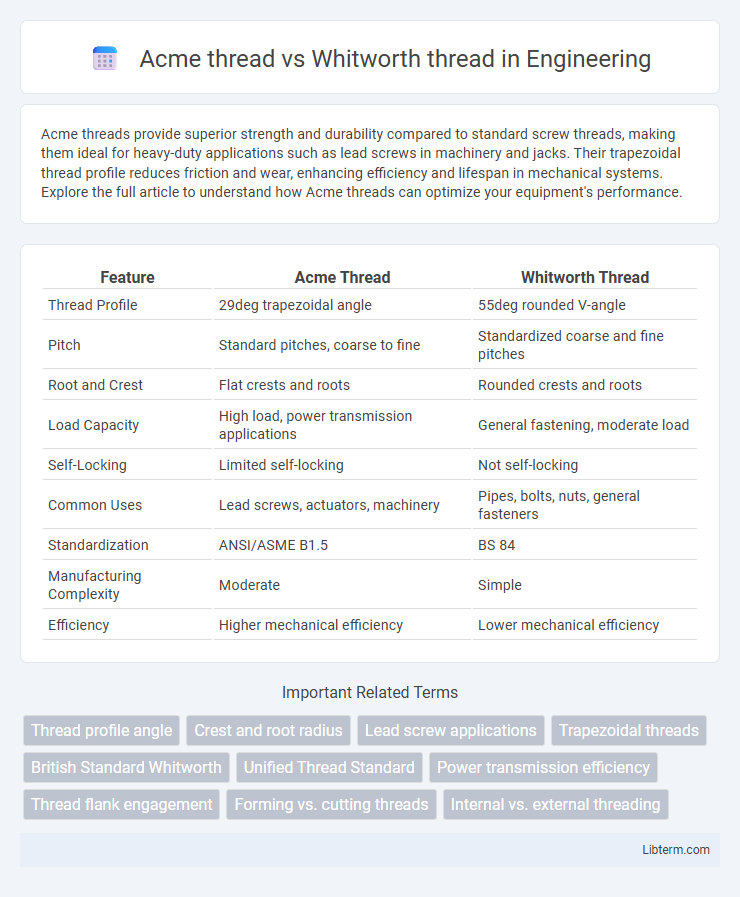

| Feature | Acme Thread | Whitworth Thread |

|---|---|---|

| Thread Profile | 29deg trapezoidal angle | 55deg rounded V-angle |

| Pitch | Standard pitches, coarse to fine | Standardized coarse and fine pitches |

| Root and Crest | Flat crests and roots | Rounded crests and roots |

| Load Capacity | High load, power transmission applications | General fastening, moderate load |

| Self-Locking | Limited self-locking | Not self-locking |

| Common Uses | Lead screws, actuators, machinery | Pipes, bolts, nuts, general fasteners |

| Standardization | ANSI/ASME B1.5 | BS 84 |

| Manufacturing Complexity | Moderate | Simple |

| Efficiency | Higher mechanical efficiency | Lower mechanical efficiency |

Introduction to Acme and Whitworth Threads

Acme threads feature a trapezoidal profile designed for power transmission and load-bearing applications, providing smoother operation and greater strength compared to traditional threads. Whitworth threads, with their distinctive 55-degree thread angle and rounded crests and roots, were among the first standardized screw threads, commonly used in British engineering and plumbing. Both thread types serve specific industrial purposes, with Acme threads favored in machinery requiring high durability and Whitworth threads employed in fastening and pipe fitting.

Historical Background of Thread Standards

The Whitworth thread, established by Sir Joseph Whitworth in 1841, was the first standardized thread system and laid the foundation for industrial screw threads by defining a 55-degree thread angle with rounded roots and crests. Acme threads, introduced in the early 20th century by the Acme thread company, evolved from the Whitworth design with a 29-degree thread angle to provide better load-bearing capacity and smoother motion in power screws and lead screws. These historical developments in thread standards reflect the transition from early mechanical fastening methods toward optimized designs for specific industrial applications.

Acme Thread Profile: Design and Features

The Acme thread profile features a trapezoidal shape with a 29-degree flank angle, designed to provide high strength and smooth engagement ideal for power transmission and lead screws. Its flat crests and roots reduce wear and facilitate easier machining compared to Whitworth threads, which have rounded crests and a 55-degree angle. Acme threads also offer superior load-carrying capacity and are commonly used in industrial applications requiring precise motion control.

Whitworth Thread Profile: Design and Features

Whitworth thread profile features a 55-degree thread angle with rounded crests and roots, promoting smoother engagement and enhanced strength in fastening applications. Its standardized design, established by Sir Joseph Whitworth in 1841, ensures compatibility across British and Commonwealth engineering systems. The thread's curved flanks reduce stress concentration, leading to improved fatigue resistance and durability compared to sharper-profile threads.

Key Differences: Acme vs Whitworth Threads

Acme threads feature a 29-degree thread angle with trapezoidal profiles designed for high load applications and smoother motion, whereas Whitworth threads have a 55-degree thread angle with rounded crests primarily used in pipe fittings and fasteners. Acme threads offer higher strength and efficiency due to their thicker thread roots and flat crests, making them ideal for power screws and lead screws, while Whitworth threads provide better sealing and are suited for general-purpose fastening. The dimensional standards differ with Acme threads standardized by ANSI B1.5 and Whitworth threads by BS EN 10226-1, impacting interchangeability and application specificity.

Strength and Performance Comparison

Acme threads feature a trapezoidal profile with a 29deg thread angle, providing superior load-carrying capacity and smooth engagement under heavy loads compared to the 55deg thread angle of Whitworth threads, which are designed for general-purpose fastening. The wider thread surface of Acme threads distributes stress more evenly, reducing wear and enhancing durability in power transmission applications. Whitworth threads, while effective for basic fastening, exhibit lower strength and performance under high torque and repeated load cycles, making Acme threads preferable in industrial machinery requiring robust and reliable power transmission.

Common Applications for Acme Threads

Acme threads are commonly used in lead screws, machine tools, and linear actuators due to their durability and efficient power transmission capabilities. These threads are ideal for applications requiring high load capacity and smooth movement, such as vises, jacks, and presses. In contrast, Whitworth threads are typically employed in general fastening applications and pipe fittings where standardized thread forms are essential.

Common Applications for Whitworth Threads

Whitworth threads are primarily used in British standard fittings, pipe threads, and historical machinery due to their rounded profile that provides strong shear resistance and effective sealing in fluid systems. Common applications include plumbing pipe connections, automotive parts, and vintage industrial equipment where standardized threading ensures reliable assembly. Their widespread use in maintenance and restoration projects highlights their continued importance in engineering and mechanical repairs.

Selection Criteria: Choosing the Right Thread Type

Selecting between Acme and Whitworth threads depends on application requirements such as load capacity and ease of manufacturing. Acme threads offer superior strength and smoother movement, making them ideal for power transmission and heavy-duty machinery. Whitworth threads, known for their rounded profile and corrosion resistance, are preferable in applications where vibration resistance and sealing capabilities are critical.

Summary and Final Recommendations

Acme threads feature a 29-degree thread angle with trapezoidal profiles ideal for power transmission and high load applications, offering smoother engagement and greater durability. Whitworth threads, with a 55-degree thread angle and rounded roots, provide superior resistance to fatigue and corrosion, commonly used in piping and fasteners requiring tight sealing. For heavy-duty linear motion or power screws, Acme threads are recommended, while Whitworth threads excel in applications demanding robust sealing and vibration resistance.

Acme thread Infographic

libterm.com

libterm.com