Post-tensioning is a technique used to reinforce concrete by applying tension to steel tendons within the structure, significantly increasing its strength and durability. This method allows for longer spans, thinner slabs, and reduced cracking compared to traditional reinforcement. Discover how post-tensioning can enhance your construction projects by exploring the detailed advantages and applications outlined in the rest of the article.

Table of Comparison

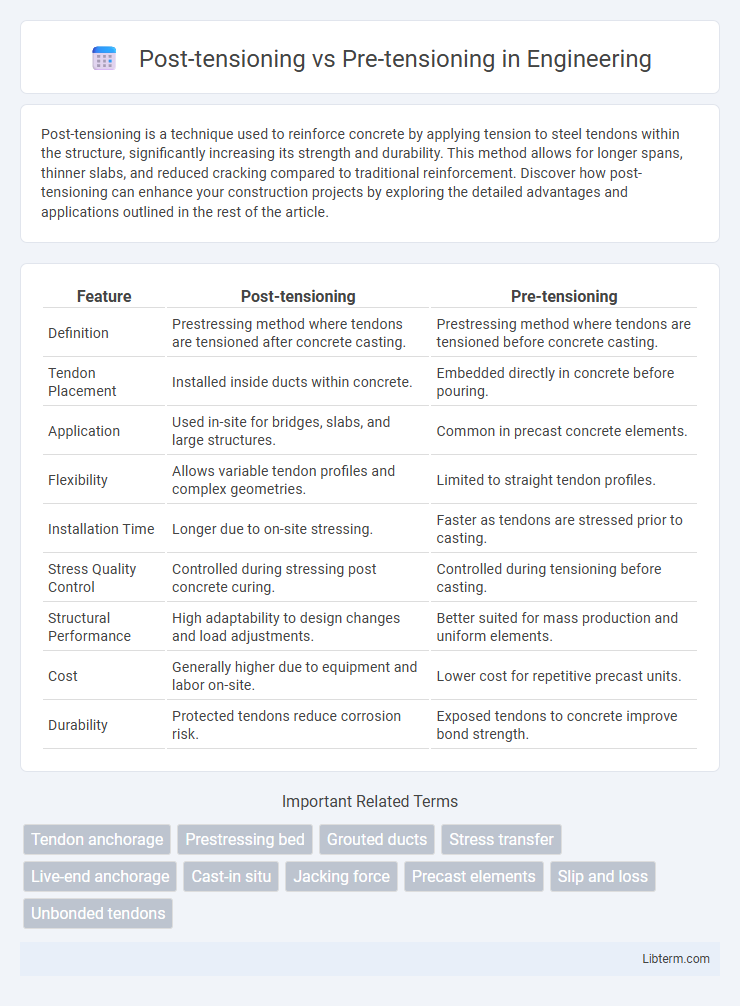

| Feature | Post-tensioning | Pre-tensioning |

|---|---|---|

| Definition | Prestressing method where tendons are tensioned after concrete casting. | Prestressing method where tendons are tensioned before concrete casting. |

| Tendon Placement | Installed inside ducts within concrete. | Embedded directly in concrete before pouring. |

| Application | Used in-site for bridges, slabs, and large structures. | Common in precast concrete elements. |

| Flexibility | Allows variable tendon profiles and complex geometries. | Limited to straight tendon profiles. |

| Installation Time | Longer due to on-site stressing. | Faster as tendons are stressed prior to casting. |

| Stress Quality Control | Controlled during stressing post concrete curing. | Controlled during tensioning before casting. |

| Structural Performance | High adaptability to design changes and load adjustments. | Better suited for mass production and uniform elements. |

| Cost | Generally higher due to equipment and labor on-site. | Lower cost for repetitive precast units. |

| Durability | Protected tendons reduce corrosion risk. | Exposed tendons to concrete improve bond strength. |

Introduction to Post-tensioning and Pre-tensioning

Post-tensioning and pre-tensioning are advanced concrete reinforcement techniques used to improve structural performance by applying tension to steel tendons. In pre-tensioning, steel tendons are tensioned before concrete is cast, creating a strong bond as the concrete hardens, which enhances load-bearing capacity. Post-tensioning involves tensioning steel tendons after the concrete has cured, allowing for precise adjustments that optimize strength and reduce material usage in beams, slabs, and bridges.

Fundamental Concepts in Prestressed Concrete

Post-tensioning involves casting concrete first and then applying tension to tendons, allowing for controlled stress distribution after the concrete gains strength. Pre-tensioning requires stretching the steel tendons before concrete placement, transferring stress immediately upon curing and enhancing bond strength. Both methods aim to improve load capacity and crack resistance in prestressed concrete structures by inducing beneficial compressive stresses.

Key Differences Between Post-tensioning and Pre-tensioning

Post-tensioning involves tensioning steel tendons after the concrete has hardened, allowing for more flexible design and longer spans, while pre-tensioning applies tension to steel strands before pouring concrete, resulting in higher bond strength between concrete and steel. Post-tensioning tends to be more effective in reducing cracking and deflection in structures, whereas pre-tensioning offers superior quality control in factory settings due to its precast nature. The choice between post-tensioning and pre-tensioning depends on project requirements such as structural complexity, span length, and construction environment.

Materials and Equipment Used

Post-tensioning utilizes high-strength steel tendons, typically coated with grease or surrounded by plastic sheathing, installed in ducts or sleeves before concrete hardens; specialized hydraulic jacks and anchorage systems are essential for tensioning tendons after concrete curing. Pre-tensioning employs pre-stressed steel strands or wires stretched on a rigid bed prior to concrete casting, requiring tensioning beds and anchorage devices to maintain stress as concrete sets. Both methods demand precise material specifications and durable equipment to ensure structural integrity and effective stress transfer in concrete elements.

Installation Procedures and Techniques

Post-tensioning involves placing ducts within the concrete formwork before pouring, followed by tensioning steel tendons after the concrete has gained sufficient strength, ensuring controlled stress application and reducing cracking. Pre-tensioning requires tensioning steel tendons on a casting bed before concrete is poured over them, with the bond transferring tension to the concrete once it hardens and the tendons are cut free. The installation procedure of post-tensioning is more flexible on-site and suitable for cast-in-place structures, while pre-tensioning is typically prefabricated in controlled environments, allowing for faster construction of standard components.

Structural Performance Comparison

Post-tensioning offers superior control of structural deflections and crack widths compared to pre-tensioning, due to the ability to apply stress after concrete has gained sufficient strength. Pre-tensioning provides high initial prestress but may lead to less efficient stress transfer in longer spans, impacting load distribution and durability. Structural performance in post-tensioned systems generally results in enhanced load-bearing capacity, improved serviceability, and increased adaptability for complex geometries.

Advantages of Post-tensioning

Post-tensioning provides enhanced structural flexibility, allowing for longer spans and thinner slabs compared to pre-tensioning, which results in material savings and architectural versatility. The technique facilitates on-site tensioning, offering adaptability in complex or irregular construction projects where pre-tensioned elements may be impractical. Post-tensioning also reduces cracking and deflection due to continuous tension adjustments, improving durability and service life of concrete structures.

Benefits of Pre-tensioning

Pre-tensioning offers enhanced bond strength between steel tendons and concrete, resulting in improved structural performance and durability. This method allows for faster construction cycles due to precast elements being produced off-site under controlled conditions. Pre-tensioning is particularly beneficial in applications requiring high volume production of standard components, such as beams and slabs, where consistent quality and cost efficiency are essential.

Common Applications in Construction

Post-tensioning is commonly used in bridge decks, parking garages, and high-rise buildings where longer spans and thinner slabs require enhanced load-bearing capacity and crack control. Pre-tensioning is typically applied in the precast concrete industry for manufacturing beams, slabs, and railroad ties, providing high early strength and uniform tensioning in controlled factory environments. Both techniques improve structural performance but are selected based on construction site conditions and project specifications.

Choosing the Right Technique for Your Project

Post-tensioning and pre-tensioning are crucial methods in concrete reinforcement, each suited for different structural demands and project scales. Post-tensioning allows for greater control over tension applied to tendons after concrete curing, ideal for long-span bridges and slabs requiring high strength and reduced cracking. Pre-tensioning, performed before concrete placement, is cost-effective for mass-produced elements like beams and slabs in controlled factory settings, offering enhanced durability and load distribution.

Post-tensioning Infographic

libterm.com

libterm.com