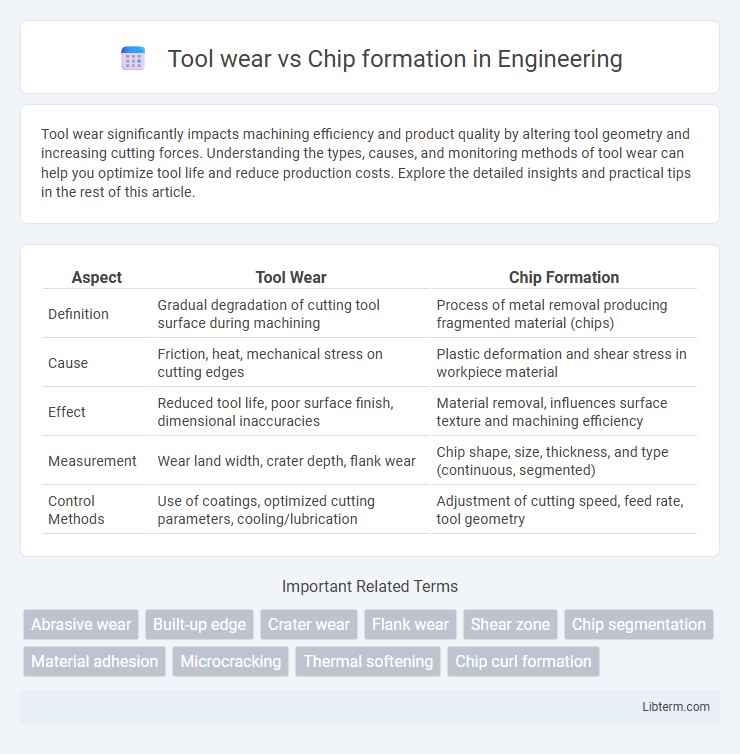

Tool wear significantly impacts machining efficiency and product quality by altering tool geometry and increasing cutting forces. Understanding the types, causes, and monitoring methods of tool wear can help you optimize tool life and reduce production costs. Explore the detailed insights and practical tips in the rest of this article.

Table of Comparison

| Aspect | Tool Wear | Chip Formation |

|---|---|---|

| Definition | Gradual degradation of cutting tool surface during machining | Process of metal removal producing fragmented material (chips) |

| Cause | Friction, heat, mechanical stress on cutting edges | Plastic deformation and shear stress in workpiece material |

| Effect | Reduced tool life, poor surface finish, dimensional inaccuracies | Material removal, influences surface texture and machining efficiency |

| Measurement | Wear land width, crater depth, flank wear | Chip shape, size, thickness, and type (continuous, segmented) |

| Control Methods | Use of coatings, optimized cutting parameters, cooling/lubrication | Adjustment of cutting speed, feed rate, tool geometry |

Introduction to Tool Wear and Chip Formation

Tool wear refers to the gradual degradation of cutting tools during machining processes, impacting surface finish and dimensional accuracy. Chip formation is the process of material removal where a continuous or segmented chip is generated as the cutting tool engages the workpiece. Understanding the interaction between tool wear and chip formation is crucial for optimizing tool life, machining efficiency, and overall manufacturing quality.

Fundamental Principles of Tool Wear

Tool wear results from mechanical, thermal, and chemical interactions between the cutting tool and workpiece during metal cutting, directly affecting chip formation quality and efficiency. Abrasion, adhesion, diffusion, and oxidation are fundamental mechanisms driving tool wear, influencing chip shape, size, and surface finish. Understanding these wear processes is essential for optimizing tool materials and cutting parameters to enhance chip formation and prolong tool life.

Types of Tool Wear in Machining

Tool wear during machining significantly influences chip formation, affecting surface finish and tool life. Common types of tool wear include abrasive wear, caused by hard particles in the workpiece; adhesive wear, resulting from metal transfer between tool and workpiece; and diffusion wear, occurring at high temperatures through material exchange. Understanding these wear mechanisms is essential for optimizing cutting conditions and selecting appropriate tool materials to enhance machining efficiency.

Mechanisms of Chip Formation

The mechanisms of chip formation significantly influence tool wear during machining processes, as the type of chip--continuous, discontinuous, or built-up edge--affects the cutting forces and thermal loads on the tool. Continuous chips tend to produce less abrasive wear due to smoother shear zones, while discontinuous chips cause higher impact stresses and accelerated tool abrasion. Understanding the interaction between chip formation mechanisms and material properties enables optimization of cutting parameters to minimize tool degradation and improve machining efficiency.

Influence of Tool Wear on Chip Morphology

Tool wear significantly impacts chip morphology by altering the cutting edge geometry and friction conditions during machining. Increased tool wear causes changes in chip thickness, shape, and segmentation patterns, often resulting in irregular, brittle, or serrated chips. These variations in chip formation not only affect surface finish but also influence cutting forces and thermal loads, accelerating tool degradation.

Factors Affecting Tool Wear and Chip Formation

Tool wear and chip formation are significantly influenced by cutting speed, feed rate, and tool material properties, which alter the temperature and stress during machining. Higher cutting speeds increase temperature at the cutting edge, accelerating tool wear and affecting chip morphology from continuous to segmented forms. Tool coating and cooling methods directly impact heat dissipation, reducing wear rate and improving chip removal efficiency in metal cutting processes.

Relationship between Cutting Parameters and Chip Formation

Cutting parameters such as cutting speed, feed rate, and depth of cut significantly influence chip formation and tool wear in machining processes. Higher cutting speeds tend to produce thinner, more continuous chips, reducing tool wear by minimizing built-up edge formation, while increased feed rates typically generate thicker chips that can accelerate tool degradation due to higher cutting forces and temperature. Optimizing these parameters enhances chip control, leading to improved surface finish and extended tool life.

Impact of Tool Material on Wear and Chip Formation

Tool material significantly affects wear rate and chip formation during machining processes. Harder materials like carbide exhibit superior wear resistance, resulting in more uniform chips with reduced plastic deformation, while softer tool materials tend to wear faster, causing irregular chips and increased cutting forces. Optimizing tool material selection enhances tool life and improves chip morphology, directly influencing machining efficiency and surface quality.

Monitoring and Analyzing Tool Wear via Chip Characteristics

Monitoring tool wear through chip formation analysis provides critical insights into the cutting process efficiency and tool life prediction. Variations in chip morphology, such as thickness, color, and segmentation, directly correlate with tool wear stages, enabling real-time assessment and preventive maintenance. Advanced image processing techniques and sensor data integration enhance the accuracy of detecting wear patterns by quantifying chip characteristics for optimized machining performance.

Strategies to Minimize Tool Wear and Optimize Chip Formation

Effective strategies to minimize tool wear and optimize chip formation include selecting appropriate cutting parameters such as feed rate, cutting speed, and depth of cut to reduce tool stress and generate favorable chip morphology. Utilizing advanced tool coatings and materials like carbide or ceramics enhances wear resistance, while proper coolant application controls temperature and improves chip evacuation. Implementing real-time monitoring systems enables early detection of tool wear, allowing timely adjustments to maintain surface quality and machining efficiency.

Tool wear Infographic

libterm.com

libterm.com