Ferritic stainless steels are known for their excellent resistance to corrosion and stress corrosion cracking, making them ideal for automotive and industrial applications. Their magnetic properties and good formability provide durability and strength in high-temperature environments. Discover more about the unique advantages and applications of ferritic steels in the rest of this article.

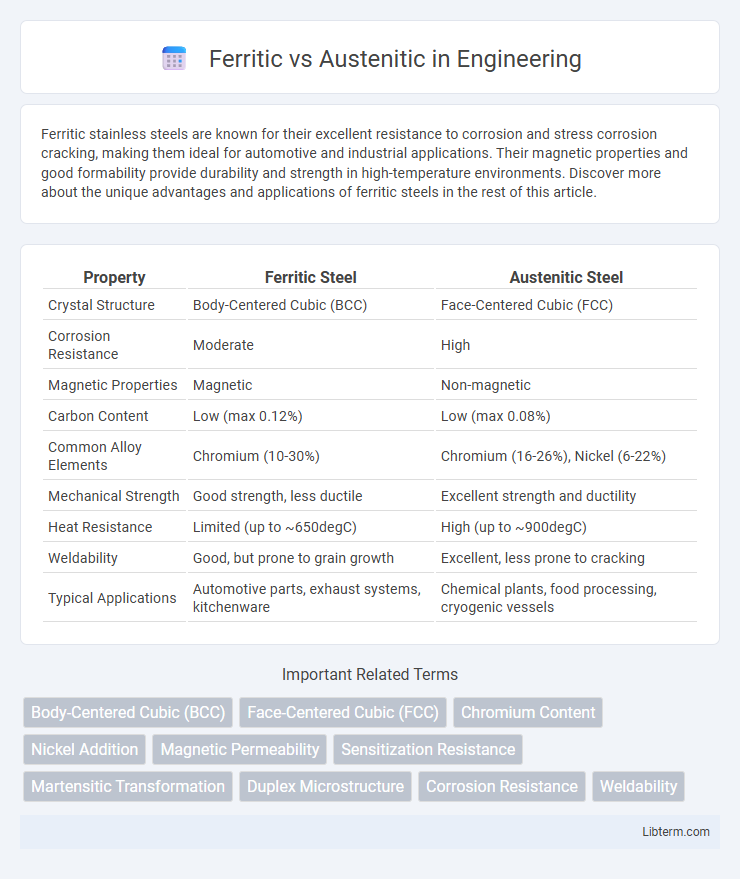

Table of Comparison

| Property | Ferritic Steel | Austenitic Steel |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Corrosion Resistance | Moderate | High |

| Magnetic Properties | Magnetic | Non-magnetic |

| Carbon Content | Low (max 0.12%) | Low (max 0.08%) |

| Common Alloy Elements | Chromium (10-30%) | Chromium (16-26%), Nickel (6-22%) |

| Mechanical Strength | Good strength, less ductile | Excellent strength and ductility |

| Heat Resistance | Limited (up to ~650degC) | High (up to ~900degC) |

| Weldability | Good, but prone to grain growth | Excellent, less prone to cracking |

| Typical Applications | Automotive parts, exhaust systems, kitchenware | Chemical plants, food processing, cryogenic vessels |

Introduction to Ferritic and Austenitic Stainless Steels

Ferritic stainless steels contain high chromium content (typically 10.5-27%) and low carbon, offering excellent resistance to stress corrosion cracking and good magnetic properties, commonly used in automotive and industrial applications. Austenitic stainless steels feature high chromium and nickel content with low carbon, providing superior corrosion resistance, ductility, and non-magnetic characteristics, making them ideal for chemical processing and food industry equipment. Both types differ significantly in microstructure; ferritic steels have a body-centered cubic (BCC) structure, while austenitic steels exhibit a face-centered cubic (FCC) structure.

Chemical Composition Differences

Ferritic stainless steels primarily consist of high chromium content (typically 10.5% to 30%) with very low carbon levels, and contain little or no nickel, enhancing corrosion resistance and magnetic properties. Austenitic stainless steels feature higher levels of nickel (commonly 8% to 10%) and chromium (16% to 26%), combined with higher carbon content, which improves ductility and toughness. The key chemical composition difference lies in the nickel presence, which stabilizes the austenite phase, while ferritic grades rely on chromium to maintain their body-centered cubic structure.

Crystal Structure Comparison

Ferritic steels have a body-centered cubic (BCC) crystal structure, which provides higher magnetic permeability and better resistance to stress corrosion cracking, but lower ductility compared to austenitic steels. Austenitic steels exhibit a face-centered cubic (FCC) crystal structure, resulting in superior toughness, ductility, and excellent corrosion resistance, especially in cryogenic environments. The difference in crystal lattice arrangement directly influences mechanical properties, corrosion behavior, and magnetic characteristics essential for selecting steel types in industrial applications.

Corrosion Resistance Properties

Ferritic stainless steels exhibit moderate corrosion resistance, particularly effective against stress corrosion cracking and oxidation at elevated temperatures. Austenitic stainless steels offer superior corrosion resistance in a wide range of environments, including acidic and chloride-rich conditions, due to their higher chromium and nickel content. The presence of stable austenite microstructure enhances toughness and resistance to pitting and crevice corrosion compared to ferritic grades.

Mechanical Strength and Ductility

Ferritic stainless steels exhibit higher mechanical strength but lower ductility compared to austenitic stainless steels, making them suitable for applications requiring wear resistance and structural stability. Austenitic steels offer superior ductility and toughness due to their face-centered cubic crystal structure, ideal for forming and impact-resistant applications. The disparity in mechanical properties arises from the differing microstructures, where ferritic steels have a body-centered cubic lattice and lower nickel content, enhancing strength but reducing flexibility.

Magnetic Properties

Ferritic stainless steels exhibit strong magnetic properties due to their body-centered cubic (BCC) crystal structure, which allows unpaired electron spins to align and create magnetism. Austenitic stainless steels, characterized by a face-centered cubic (FCC) structure, are generally non-magnetic because the symmetrical atomic arrangement prevents the alignment of magnetic domains. The difference in magnetic behavior makes ferritic steels suitable for applications requiring magnetic permeability, while austenitic steels are preferred when non-magnetic materials are essential.

Common Applications

Ferritic stainless steels are commonly used in automotive exhaust systems, kitchen utensils, and architectural panels due to their excellent corrosion resistance and magnetic properties. Austenitic stainless steels dominate in chemical processing equipment, food processing machinery, and medical instruments because of their superior toughness, ductility, and resistance to a wide range of corrosive environments. Both types find extensive applications in the construction industry, with ferritic grades favored for their thermal conductivity and austenitic grades for their strength and formability.

Weldability and Fabrication

Ferritic stainless steels exhibit better weldability with reduced risk of hot cracking due to their body-centered cubic (BCC) structure, but they require controlled cooling to prevent brittleness. Austenitic stainless steels, characterized by their face-centered cubic (FCC) structure, offer excellent weldability and corrosion resistance, although they are prone to sensitization and grain growth if not properly managed during fabrication. Both types demand specific welding techniques, such as low heat input and proper filler materials, to optimize joint strength and minimize distortion in fabrication processes.

Cost and Availability

Ferritic stainless steel typically costs less than austenitic stainless steel due to its lower nickel content and simpler manufacturing process. Ferritic grades are widely available and preferred for budget-sensitive applications where moderate corrosion resistance is sufficient. Austenitic stainless steel, containing higher nickel and chromium, offers superior corrosion resistance but comes at a higher price and may face supply constraints linked to fluctuating nickel markets.

Choosing Between Ferritic and Austenitic Steels

Choosing between ferritic and austenitic steels depends on factors like corrosion resistance, mechanical properties, and cost-efficiency. Ferritic steels offer superior resistance to stress corrosion cracking and are magnetic, making them ideal for automotive and industrial applications requiring good ductility and moderate corrosion resistance. Austenitic steels provide excellent corrosion resistance and high strength at elevated temperatures, benefiting chemical processing, food industry, and marine environments where durability and corrosion resistance are critical.

Ferritic Infographic

libterm.com

libterm.com