Buckling capacity defines the maximum load a structural element can withstand before experiencing sudden lateral deflection or collapse due to instability. It is influenced by factors like material properties, cross-sectional geometry, length, and boundary conditions. Explore the article to understand how to evaluate and enhance your structure's buckling resistance effectively.

Table of Comparison

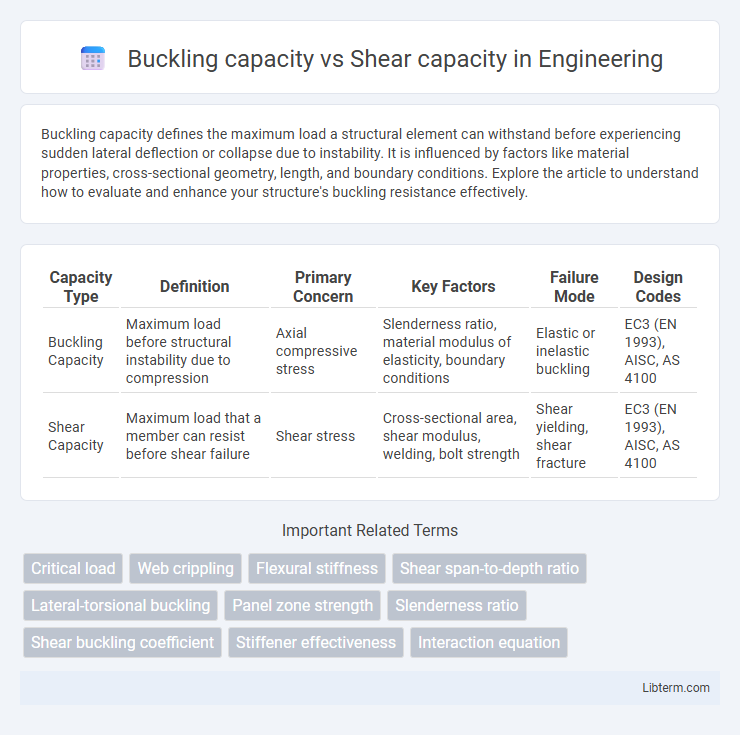

| Capacity Type | Definition | Primary Concern | Key Factors | Failure Mode | Design Codes |

|---|---|---|---|---|---|

| Buckling Capacity | Maximum load before structural instability due to compression | Axial compressive stress | Slenderness ratio, material modulus of elasticity, boundary conditions | Elastic or inelastic buckling | EC3 (EN 1993), AISC, AS 4100 |

| Shear Capacity | Maximum load that a member can resist before shear failure | Shear stress | Cross-sectional area, shear modulus, welding, bolt strength | Shear yielding, shear fracture | EC3 (EN 1993), AISC, AS 4100 |

Understanding Buckling Capacity

Buckling capacity refers to the maximum load a structural member can withstand before experiencing sudden lateral instability, which is critical in slender columns subjected to compressive forces. It depends on factors such as the member's length, cross-sectional geometry, material properties, and boundary conditions, influencing the critical load at which buckling occurs. Understanding buckling capacity is essential for designing safe and efficient structural elements to prevent catastrophic failure under compressive loads.

Shear Capacity Defined

Shear capacity is defined as the maximum shear force a structural element can resist before failure, determined by material strength, cross-sectional shape, and loading conditions. It plays a critical role in ensuring stability under transverse forces, preventing sudden failure such as shear cracks or web buckling. Unlike buckling capacity, which relates to compressive load-induced instability, shear capacity specifically addresses resistance to sliding and diagonal tension failures within the material.

Key Differences: Buckling vs Shear

Buckling capacity refers to the maximum load a structural member can withstand before experiencing sudden lateral instability or failure under compressive stress, while shear capacity is the maximum load a material can resist before sliding or shearing along a plane. Buckling primarily concerns slender components subjected to compressive forces causing deformation, whereas shear capacity addresses resistance to transverse forces causing internal sliding failure. Understanding the distinct failure modes is crucial in structural design to ensure safety and optimize load-bearing performance under different loading conditions.

Factors Affecting Buckling Capacity

Buckling capacity is influenced by factors such as slenderness ratio, material properties, and boundary conditions, which determine the load at which a structural member becomes unstable. Shear capacity primarily depends on the cross-sectional area, shear strength of the material, and presence of web stiffeners but is less sensitive to slenderness effects compared to buckling. Understanding the interplay between these factors is crucial for designing safe structural elements that resist both buckling and shear failure modes.

Parameters Influencing Shear Capacity

Shear capacity is influenced primarily by parameters such as the cross-sectional area, material strength, and the presence of shear reinforcement like stirrups or webs. Other critical factors include the geometry of the structural member, the type and distribution of loads, and boundary conditions affecting stress distribution. In contrast, buckling capacity is mainly governed by slenderness ratio, material modulus of elasticity, and structural support conditions.

Structural Failures: Buckling vs Shear

Buckling capacity determines a structural element's ability to withstand compressive forces before sudden lateral deflection occurs, often causing catastrophic failure in slender columns and thin-walled components. Shear capacity measures resistance to shear forces that induce sliding deformation, critical in beams and connections where abrupt diagonal cracking or shear failure can compromise integrity. Understanding the interplay between buckling and shear capacities guides engineers in designing safer, more resilient structures by preventing distinct yet equally destructive failure modes.

Calculation Methods for Buckling Capacity

Buckling capacity calculation methods primarily involve solving differential equations from classical Euler buckling theory, incorporating factors such as member length, cross-sectional moment of inertia, and modulus of elasticity. Advanced approaches use finite element analysis (FEA) to simulate buckling behavior under compressive loads, accounting for imperfections and material nonlinearity. Design codes, such as AISC and Eurocode, provide specific formulas and reduction factors to ensure safe buckling load predictions based on empirical and theoretical studies.

Calculating Shear Capacity in Structures

Shear capacity in structures is calculated by evaluating the material's shear strength and the cross-sectional area subjected to shear forces, often using formulas derived from standards like AISC or Eurocode. It involves determining the maximum shear force the structural element can withstand without failure, considering factors such as shear yield stress and web thickness, especially in beams and girders. Accurate shear capacity calculation ensures safety against shearing failure, complementing buckling analysis which primarily addresses compressive stability.

Design Strategies: Enhancing Buckling and Shear Resistance

Design strategies to enhance buckling and shear resistance involve selecting high-strength materials and optimizing cross-sectional geometry to increase stiffness and load-bearing capacity. Incorporating stiffeners, bracing systems, and shear panels improves structural stability, preventing premature buckling and shear failure under applied loads. Advanced computational modeling enables precise prediction of critical buckling loads and shear stresses, guiding reinforcement placement and minimizing material usage while maximizing safety.

Practical Applications: Buckling and Shear in Engineering

Buckling capacity determines the maximum axial load a structural element can endure before failure due to instability, critical in slender columns and compression members in buildings and bridges. Shear capacity defines the material's ability to resist transverse forces, essential in beams, girders, and shear walls to prevent sudden shear failure. Engineers optimize designs by accurately calculating both capacities to ensure safety and performance in load-bearing structures subjected to axial and lateral forces.

Buckling capacity Infographic

libterm.com

libterm.com