Fluid friction occurs when a fluid opposes the motion of an object moving through it, causing resistance due to the fluid's viscosity. This type of friction influences various phenomena, from the drag experienced by vehicles to the flow of liquids in pipes. Discover how understanding fluid friction can improve your efficiency in engineering and daily applications by reading the rest of the article.

Table of Comparison

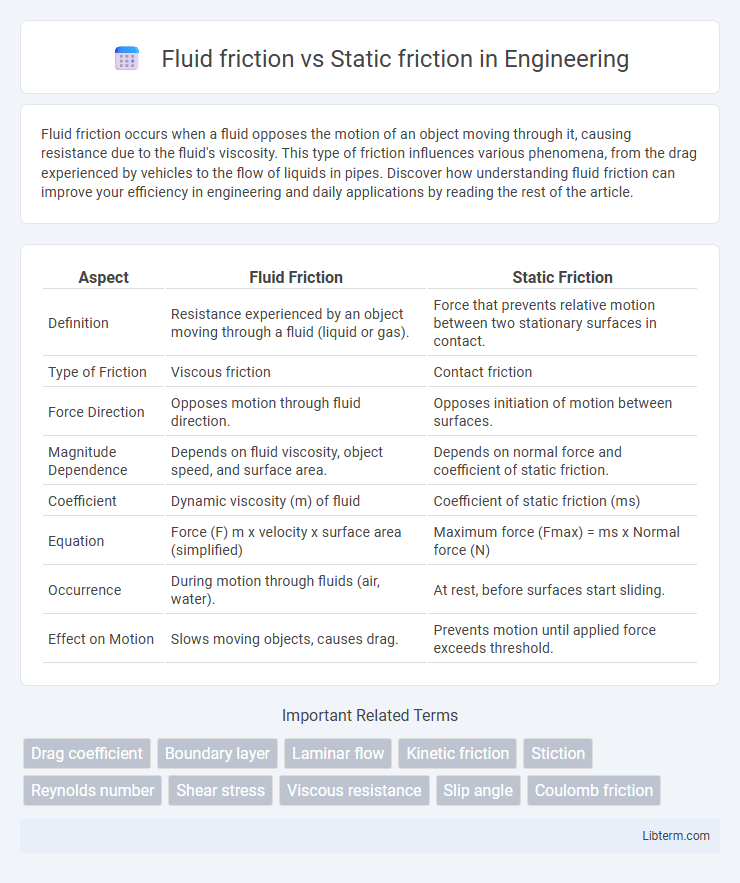

| Aspect | Fluid Friction | Static Friction |

|---|---|---|

| Definition | Resistance experienced by an object moving through a fluid (liquid or gas). | Force that prevents relative motion between two stationary surfaces in contact. |

| Type of Friction | Viscous friction | Contact friction |

| Force Direction | Opposes motion through fluid direction. | Opposes initiation of motion between surfaces. |

| Magnitude Dependence | Depends on fluid viscosity, object speed, and surface area. | Depends on normal force and coefficient of static friction. |

| Coefficient | Dynamic viscosity (m) of fluid | Coefficient of static friction (ms) |

| Equation | Force (F) m x velocity x surface area (simplified) | Maximum force (Fmax) = ms x Normal force (N) |

| Occurrence | During motion through fluids (air, water). | At rest, before surfaces start sliding. |

| Effect on Motion | Slows moving objects, causes drag. | Prevents motion until applied force exceeds threshold. |

Introduction to Friction: Understanding the Basics

Friction is the resistive force that opposes the relative motion between two surfaces in contact, with static friction preventing motion initiation and fluid friction resisting the movement of objects through liquids or gases. Static friction arises from the microscopic roughness and adhesion between solid surfaces, while fluid friction depends on the viscosity and velocity of the fluid surrounding the object. Understanding these fundamental differences is essential for applications ranging from mechanical engineering to fluid dynamics, where controlling friction impacts efficiency and performance.

What is Static Friction?

Static friction is the force that resists the initiation of motion between two surfaces in contact when at rest. It acts parallel to the surfaces and varies in magnitude up to a maximum value proportional to the normal force and the coefficient of static friction. Unlike fluid friction, which occurs within or between fluids in motion, static friction prevents relative sliding until an external force overcomes it.

What is Fluid Friction?

Fluid friction, also known as viscous friction, occurs when an object moves through a fluid such as a liquid or gas, resulting in resistance against the object's motion. This type of friction depends on the viscosity of the fluid and the relative velocity between the object and the fluid. Unlike static friction, which prevents the initiation of motion between solid surfaces, fluid friction acts continuously once movement begins.

Key Differences Between Static and Fluid Friction

Static friction acts between two solid surfaces at rest relative to each other, preventing motion until the applied force exceeds a threshold, quantified by the coefficient of static friction. Fluid friction, also called viscous friction, occurs when an object moves through a fluid (liquid or gas), depending on the fluid's viscosity and the object's velocity. Key differences include static friction being a force resisting the initiation of sliding motion between solids, while fluid friction continuously opposes motion through a fluid medium and varies with speed.

Factors Affecting Static Friction

Static friction depends on the nature of the contacting surfaces and the normal force pressing them together, with rougher surfaces increasing frictional resistance. Surface texture and material composition alter microscopic contact points, directly influencing the maximum static friction before motion occurs. Environmental factors such as lubrication and temperature can also modify the adhesion and deformation at the interface, thereby affecting static friction values.

Factors Influencing Fluid Friction

Fluid friction depends on the viscosity of the fluid, the velocity of the object moving through it, and the surface area in contact with the fluid, all of which increase resistance. Temperature also plays a critical role, as higher temperatures generally decrease a fluid's viscosity, thereby reducing fluid friction. In contrast, static friction is influenced by the normal force and the nature of the contact surfaces but remains unaffected by fluid properties.

Real-World Applications of Static Friction

Static friction plays a crucial role in everyday scenarios such as walking, driving, and construction, where it prevents slipping by resisting the initiation of motion between contact surfaces. Its high coefficient between rubber tires and road surfaces allows vehicles to accelerate, decelerate, and navigate turns safely. In engineering, static friction helps maintain the stability of structures by keeping components firmly in place under various load conditions.

Real-World Examples of Fluid Friction

Fluid friction occurs when objects move through liquids or gases, such as a swimmer gliding through water or an airplane flying through air. This type of friction plays a crucial role in designing efficient ship hulls and aerodynamic vehicles to reduce drag and improve fuel efficiency. In pipes and pipelines, fluid friction affects the flow rate and energy consumption, making it essential to optimize for industrial applications.

Measuring and Calculating Static versus Fluid Friction

Static friction is measured by determining the minimum force required to initiate motion between two solid surfaces, typically calculated using the coefficient of static friction multiplied by the normal force. Fluid friction, also known as viscous drag, is calculated by assessing the resistance exerted by a fluid on a moving object, often quantified using parameters like fluid viscosity, object velocity, and the object's surface area in contact with the fluid. Precise measurement of static friction involves force sensors and controlled frictional interfaces, whereas fluid friction is evaluated through experiments such as flow rate tests and drag force measurements in fluids with known properties.

Conclusion: Choosing the Right Friction Type for Engineering Solutions

Fluid friction offers advantages in applications requiring smooth motion and reduced wear through lubricants or air resistance, while static friction provides essential resistance to prevent unwanted movement in mechanical systems. Engineering solutions must evaluate factors like load conditions, surface materials, and desired motion control to select the appropriate friction type. Optimizing friction ensures enhanced efficiency, durability, and safety tailored to specific operational demands.

Fluid friction Infographic

libterm.com

libterm.com