Soldering is a precise technique used to join metal components by melting a filler metal, or solder, to create a strong electrical and mechanical connection. Mastering proper soldering methods ensures reliable circuits, reduces the risk of cold joints, and improves the durability of your electronic projects. Explore the rest of this article to discover essential tips and best practices for flawless soldering results.

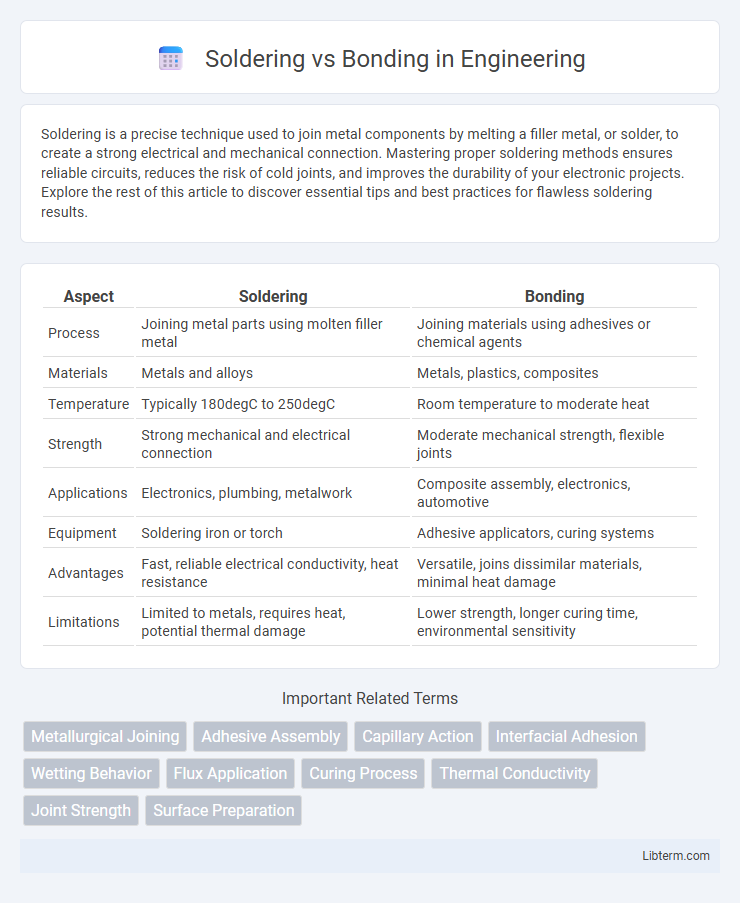

Table of Comparison

| Aspect | Soldering | Bonding |

|---|---|---|

| Process | Joining metal parts using molten filler metal | Joining materials using adhesives or chemical agents |

| Materials | Metals and alloys | Metals, plastics, composites |

| Temperature | Typically 180degC to 250degC | Room temperature to moderate heat |

| Strength | Strong mechanical and electrical connection | Moderate mechanical strength, flexible joints |

| Applications | Electronics, plumbing, metalwork | Composite assembly, electronics, automotive |

| Equipment | Soldering iron or torch | Adhesive applicators, curing systems |

| Advantages | Fast, reliable electrical conductivity, heat resistance | Versatile, joins dissimilar materials, minimal heat damage |

| Limitations | Limited to metals, requires heat, potential thermal damage | Lower strength, longer curing time, environmental sensitivity |

Introduction to Soldering and Bonding

Soldering involves joining metals by melting a filler metal with a lower melting point to create a strong electrical and mechanical bond, commonly used in electronics for circuit connections. Bonding, on the other hand, utilizes adhesives or chemical agents to join surfaces without melting, suitable for materials that cannot withstand high temperatures. Understanding these fundamental differences helps in selecting the appropriate technique for applications requiring strength, conductivity, or temperature resistance.

Definition and Basic Principles

Soldering is a process that joins metals by melting a filler metal with a lower melting point than the workpieces, creating a strong mechanical and electrical connection. Bonding involves adhering materials together using adhesives that chemically or physically interact at the interface, often without heat. Both methods rely on different principles: soldering depends on metallurgical compatibility and heat transfer, while bonding emphasizes surface chemistry and adhesive properties.

Materials Used in Soldering vs Bonding

Soldering primarily uses metal alloys such as tin-lead, lead-free tin-silver-copper, or silver solder to join components, creating a strong electrical and mechanical bond. Bonding, in contrast, employs adhesives like epoxy, silicone, or polyurethane, which cure to form durable joints without requiring high temperatures. The choice of materials in soldering versus bonding significantly influences the thermal, mechanical, and electrical properties of the final assembly.

Process Comparison: Step-by-Step Procedures

Soldering involves heating a filler metal above its melting point to create a strong, conductive joint between metal parts using a soldering iron or torch, followed by cooling to solidify the bond. Bonding, often referring to adhesive bonding, entails applying a polymer-based adhesive to surfaces, aligning the components, and curing the adhesive through heat, pressure, or chemical reaction to form a durable connection. The soldering process requires precise temperature control for proper wetting and joint integrity, whereas bonding depends on surface preparation and controlled curing conditions for optimal adhesion strength.

Strength and Durability of Joints

Soldering provides strong mechanical and electrical joints with tensile strengths ranging from 30 to 60 MPa, suitable for electronic components but may weaken under thermal cycling due to alloy fatigue. Bonding, particularly with advanced adhesives like epoxy or polyurethane, achieves high shear strength up to 40 MPa and excellent durability against vibration, moisture, and temperature variations, making it ideal for flexible and composite materials. The choice largely depends on application requirements, with soldering excelling in electrical conductivity and bonding offering enhanced joint resilience and longevity.

Applications in Various Industries

Soldering is widely used in electronics manufacturing for creating reliable electrical connections on circuit boards and in automotive components requiring conductive joins. Bonding techniques, including adhesive bonding and ultrasonic bonding, are essential in aerospace for assembling composite materials and in medical device production for joining delicate parts without excessive heat. Both methods find critical applications in consumer electronics, automotive, aerospace, and medical industries, each chosen based on material compatibility, mechanical strength, and thermal requirements.

Equipment and Tools Required

Soldering requires specialized equipment such as a soldering iron or soldering station, solder wire, flux, and often a heat-resistant mat or helping hands tool for precision and safety. Bonding, depending on the method, typically involves adhesives or bonding agents and may require surface preparation tools like sanders, cleaners, or UV curing lamps for adhesives activated by light. Both processes demand precise temperature or curing control tools to ensure strong and reliable joints in electronic or mechanical assemblies.

Cost and Time Efficiency

Soldering typically offers lower initial costs due to minimal equipment requirements and faster process times, making it ideal for high-volume electronic assembly. Bonding, while often involving higher material expenses and longer curing periods, provides superior mechanical strength and reliability in structural applications. Choosing between soldering and bonding depends on balancing the cost-effectiveness of quick assembly against the long-term benefits of durable joint performance.

Advantages and Disadvantages

Soldering provides strong electrical and thermal connections ideal for electronic components but requires heat that may damage sensitive materials. Bonding techniques, such as adhesive bonding, offer flexibility and can join dissimilar materials without heat, yet typically result in lower electrical conductivity and mechanical strength than soldering. Choosing between soldering and bonding depends on factors like thermal tolerance, mechanical load, and electrical requirements.

Choosing the Right Method for Your Project

Selecting between soldering and bonding hinges on the project's material compatibility, mechanical strength requirements, and environmental conditions. Soldering excels in creating strong, conductive joints for metals, especially in electronics and electrical assemblies, while bonding suits non-metallic materials or delicate components where heat application is undesirable. Analyzing factors such as thermal sensitivity, load-bearing demands, and exposure to moisture ensures the optimal attachment technique for durability and performance.

Soldering Infographic

libterm.com

libterm.com