Ultrasonic peening enhances metal surfaces by inducing compressive residual stresses, improving fatigue strength and resistance to stress corrosion cracking. This advanced technique uses high-frequency ultrasonic vibrations to generate plastic deformation, resulting in superior surface durability and extended component lifespan. Discover how ultrasonic peening can optimize Your metal components by exploring the rest of this article.

Table of Comparison

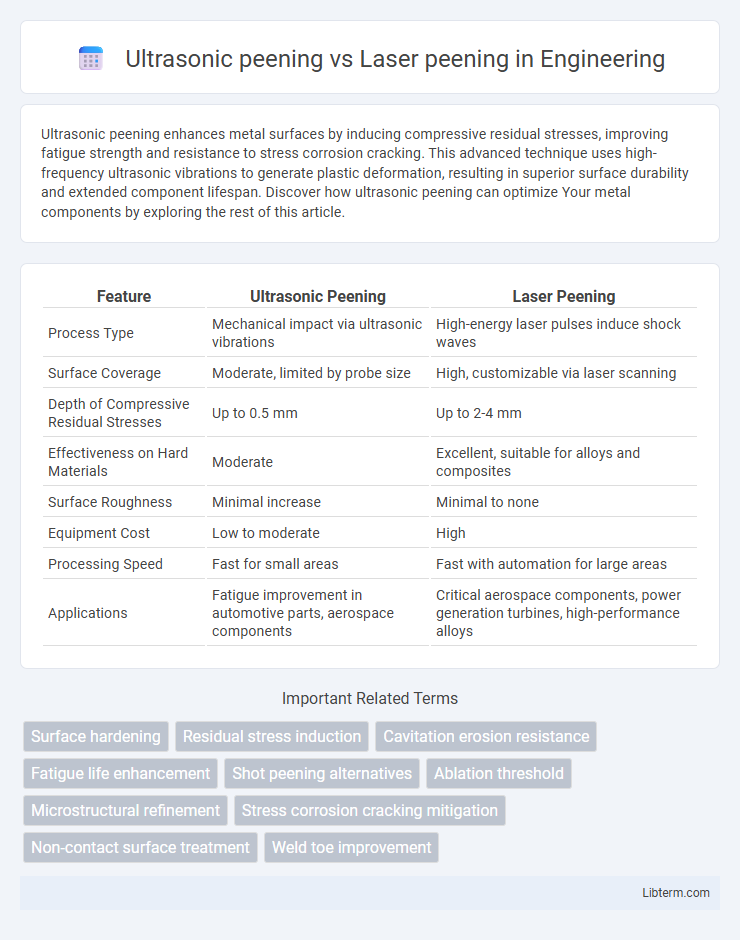

| Feature | Ultrasonic Peening | Laser Peening |

|---|---|---|

| Process Type | Mechanical impact via ultrasonic vibrations | High-energy laser pulses induce shock waves |

| Surface Coverage | Moderate, limited by probe size | High, customizable via laser scanning |

| Depth of Compressive Residual Stresses | Up to 0.5 mm | Up to 2-4 mm |

| Effectiveness on Hard Materials | Moderate | Excellent, suitable for alloys and composites |

| Surface Roughness | Minimal increase | Minimal to none |

| Equipment Cost | Low to moderate | High |

| Processing Speed | Fast for small areas | Fast with automation for large areas |

| Applications | Fatigue improvement in automotive parts, aerospace components | Critical aerospace components, power generation turbines, high-performance alloys |

Introduction to Peening Technologies

Ultrasonic peening employs high-frequency mechanical vibrations to induce beneficial compressive stresses, enhancing metal fatigue resistance and surface hardness. Laser peening uses high-energy laser pulses to generate shock waves that create deep compressive residual stresses, significantly improving material strength and durability. Both peening technologies optimize surface integrity, but laser peening typically achieves deeper stress layers and greater precision in targeting specific areas.

Understanding Ultrasonic Peening

Ultrasonic peening uses high-frequency mechanical vibrations to induce compressive residual stress and improve fatigue strength in metals by generating plastic deformation on the surface. This process is particularly effective in repairing surface cracks and enhancing wear resistance without overheating the material, making it suitable for delicate components. Compared to laser peening, ultrasonic peening offers a more controlled and cost-effective approach with less thermal impact while maintaining significant improvements in fatigue life and stress corrosion resistance.

Fundamentals of Laser Peening

Laser peening uses high-intensity laser pulses to generate shock waves that induce deep compressive residual stresses, significantly improving metal fatigue resistance compared to ultrasonic peening, which employs mechanical vibrations. The fundamentals of laser peening involve directing focused laser energy onto a metal surface covered by a protective ablative layer; this interaction produces plasma and subsequent shock waves that penetrate deeply, enhancing material strength and lifespan. Unlike ultrasonic peening, laser peening achieves greater depth and uniformity of stress distribution, making it ideal for critical aerospace and automotive components.

Key Differences Between Ultrasonic and Laser Peening

Ultrasonic peening uses high-frequency mechanical vibrations to induce compressive residual stress, while laser peening employs high-energy laser pulses to generate shock waves for the same purpose. Laser peening typically achieves deeper compressive layers and better surface finish compared to ultrasonic peening, making it more effective for improving fatigue resistance in critical components. Ultrasonic peening is generally more cost-effective and easier to implement for smaller-scale applications, whereas laser peening requires complex equipment and higher operational costs.

Equipment and Process Overview

Ultrasonic peening employs high-frequency mechanical vibrations through a sonotrode to induce compressive residual stresses, enhancing metal fatigue resistance with equipment typically comprising a generator, transducer, and vibrating tool. Laser peening uses high-energy pulsed lasers to generate shock waves on the metal surface, creating deeper compressive stress layers, requiring complex laser systems including a pulsed laser source, optics, and protective overlay. The ultrasonic process offers compact, cost-effective setups suitable for localized treatment, while laser peening demands sophisticated, high-precision equipment ideal for treating intricate geometries and thicker materials.

Applications in Industry

Ultrasonic peening enhances fatigue life and stress corrosion resistance in aerospace and automotive components by inducing compressive residual stresses on metal surfaces. Laser peening is widely applied in power generation and shipbuilding industries for improving crack growth resistance and extending service life of turbine blades and structural welds. Both techniques offer tailored surface treatments, with ultrasonic peening favored for precision in small parts and laser peening suited for large-scale, high-impact applications.

Comparative Effectiveness on Material Properties

Ultrasonic peening enhances fatigue strength and surface hardness by inducing compressive residual stresses through high-frequency mechanical impacts, making it effective for fine-grained metals and surface treatments. Laser peening generates deeper and more uniform compressive stresses via high-energy laser pulses, resulting in superior resistance to crack initiation and propagation, especially in thick or complex components. Comparative studies reveal laser peening achieves greater depth of stress penetration and improved performance in high-stress applications, while ultrasonic peening offers cost-effective surface improvement with limited depth.

Cost Analysis: Ultrasonic vs Laser Peening

Ultrasonic peening generally offers a lower initial investment and operational cost compared to laser peening due to simpler equipment and reduced energy consumption. Laser peening, while more expensive upfront with high maintenance costs, delivers deeper compressive stresses and longer-lasting fatigue resistance, potentially reducing long-term repair expenses. Cost efficiency depends on specific application needs, volume of parts processed, and desired material performance enhancements.

Advantages and Limitations of Each Method

Ultrasonic peening offers advantages such as lower equipment cost, portability, and effective surface hardening for complex geometries, but it is limited by shallower residual stress depth and lower precision compared to laser peening. Laser peening provides deeper compressive residual stresses, improved fatigue resistance, and precise control over treated areas, though it requires expensive, high-maintenance equipment and is less adaptable to complex shapes. Both methods enhance material strength and fatigue life, yet selection depends on application-specific factors like cost, depth of treatment, and component geometry.

Future Trends in Peening Technologies

Future trends in peening technologies emphasize enhanced precision and efficiency, with ultrasonic peening advancing through improved transducer designs for deeper compressive stress layers and real-time process monitoring via AI integration. Laser peening developments focus on higher power lasers and adaptive optics to achieve finer surface treatments and expanded application ranges in aerospace and automotive industries. Both methods are increasingly incorporating sustainable practices and automation to reduce energy consumption and enable scalable manufacturing processes.

Ultrasonic peening Infographic

libterm.com

libterm.com