Form drag occurs when the shape of an object disrupts airflow, creating pressure differences that resist motion. This type of drag is influenced by the object's size, contour, and frontal area, making aerodynamic design crucial to minimize resistance. Discover how understanding form drag can enhance your vehicle's efficiency in the rest of this article.

Table of Comparison

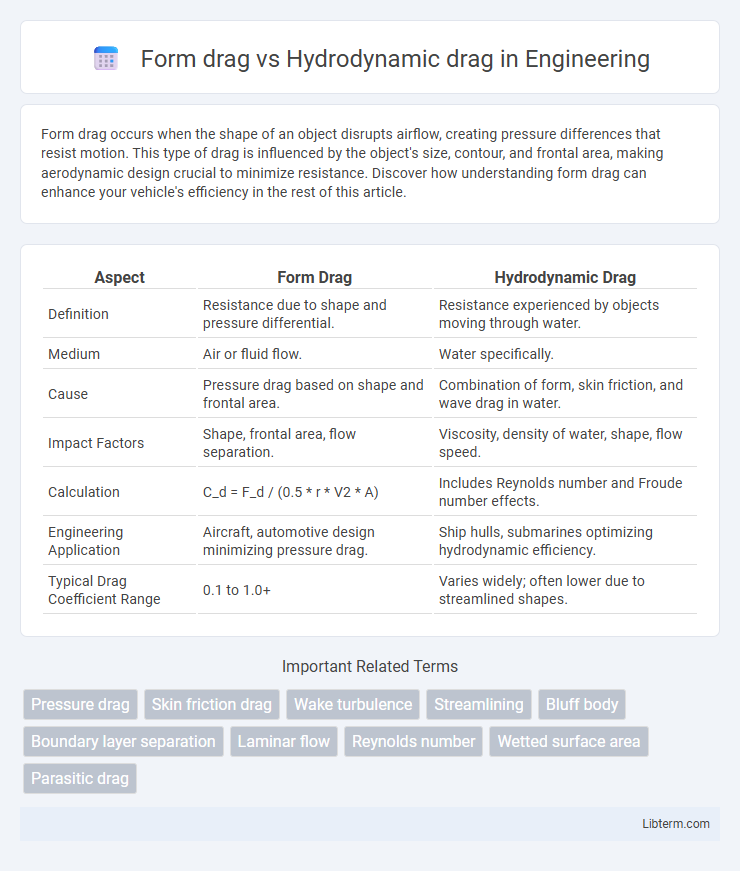

| Aspect | Form Drag | Hydrodynamic Drag |

|---|---|---|

| Definition | Resistance due to shape and pressure differential. | Resistance experienced by objects moving through water. |

| Medium | Air or fluid flow. | Water specifically. |

| Cause | Pressure drag based on shape and frontal area. | Combination of form, skin friction, and wave drag in water. |

| Impact Factors | Shape, frontal area, flow separation. | Viscosity, density of water, shape, flow speed. |

| Calculation | C_d = F_d / (0.5 * r * V2 * A) | Includes Reynolds number and Froude number effects. |

| Engineering Application | Aircraft, automotive design minimizing pressure drag. | Ship hulls, submarines optimizing hydrodynamic efficiency. |

| Typical Drag Coefficient Range | 0.1 to 1.0+ | Varies widely; often lower due to streamlined shapes. |

Introduction to Drag Forces

Drag forces in fluid dynamics primarily consist of form drag and hydrodynamic drag, both crucial in understanding resistance experienced by objects moving through liquids or gases. Form drag arises from the shape and size of an object, creating pressure differences that resist motion, while hydrodynamic drag encompasses all fluid resistance, including viscous effects and boundary layer interactions. Accurate analysis of these drag forces is essential for optimizing vehicle design, improving fuel efficiency, and enhancing performance in aerospace, automotive, and marine engineering.

Defining Form Drag

Form drag is the resistance force caused by the shape and frontal area of an object moving through a fluid, resulting from pressure differences between the front and rear surfaces. It significantly impacts the overall hydrodynamic drag, which also includes skin friction and wave-making resistance in marine environments. Understanding form drag is critical for designing streamlined hulls and reducing energy loss in vessels and underwater vehicles.

Understanding Hydrodynamic Drag

Hydrodynamic drag refers to the resistance experienced by an object moving through a fluid, primarily influenced by the fluid's viscosity and the object's shape. Unlike form drag, which stems from pressure differences caused by the object's geometry, hydrodynamic drag encompasses both viscous friction and pressure drag components within water or other fluids. Understanding hydrodynamic drag is crucial for optimizing the design of marine vessels, underwater vehicles, and swimmers to reduce energy loss and enhance efficiency.

Key Differences Between Form Drag and Hydrodynamic Drag

Form drag primarily arises from the shape and frontal area of an object moving through a fluid, causing pressure differences that resist motion. Hydrodynamic drag encompasses various resistance forces acting on bodies submerged in water, including form drag, frictional drag, and wave-making drag. The key difference lies in hydrodynamic drag being a broader category specific to water environments, while form drag is a component of drag linked to pressure distribution regardless of fluid type.

Factors Affecting Form Drag

Form drag is primarily influenced by the shape and frontal area of an object, where bluff shapes increase pressure differences causing higher drag. Surface roughness and flow separation points significantly affect form drag by disrupting laminar flow and increasing turbulence. Velocity of the fluid and fluid density directly impact the magnitude of form drag through their effect on the pressure distribution around the object.

Factors Influencing Hydrodynamic Drag

Hydrodynamic drag is influenced by factors such as fluid viscosity, surface roughness of the object, and the velocity of fluid flow, which determine the extent of frictional resistance. The shape and size of the submerged body affect pressure distribution, contributing to wave drag and pressure drag components. Turbulence and boundary layer characteristics also play crucial roles in increasing or reducing hydrodynamic drag in aquatic environments.

Real-World Examples of Form Drag

Form drag arises primarily from the shape and frontal area of an object moving through a fluid, significantly affecting vehicles like trucks, airplanes, and submarines. For instance, boxy trucks experience higher form drag due to flat surfaces disrupting airflow, increasing fuel consumption. In contrast, streamlined shapes of fighter jets or torpedo designs reduce form drag, enhancing speed and efficiency in air or water.

Applications of Hydrodynamic Drag in Engineering

Hydrodynamic drag plays a crucial role in engineering applications such as ship design, underwater vehicle development, and fluid machinery optimization, where minimizing resistance improves efficiency and performance. Engineers analyze flow patterns around submerged bodies to reduce turbulence and enhance streamlined shapes, resulting in lower energy consumption and increased speed. Computational fluid dynamics (CFD) simulations are extensively used to predict hydrodynamic drag forces, enabling the design of hulls, propellers, and turbines that maximize operational effectiveness in aquatic environments.

Strategies for Minimizing Drag

Minimizing form drag involves streamlining the shape of an object to reduce pressure differences and promote smooth airflow or water flow, such as using tapered edges and smooth surfaces. Hydrodynamic drag reduction relies on optimizing surface texture and using materials that lessen viscous friction in water, including applying riblets or hydrophobic coatings. Employing computational fluid dynamics (CFD) simulations helps in designing shapes and surfaces that effectively reduce both form and hydrodynamic drag for vehicles and vessels.

Future Trends in Drag Research

Future trends in drag research emphasize advanced computational fluid dynamics (CFD) models and machine learning algorithms to accurately predict form drag and hydrodynamic drag in complex shapes and turbulent flows. Innovations in biomimetic design inspired by marine animals aim to minimize hydrodynamic drag by optimizing surface textures and streamline contours. Emerging materials with adaptive morphing capabilities provide dynamic adjustments to reduce form drag in real-time, enhancing performance in automotive and maritime industries.

Form drag Infographic

libterm.com

libterm.com