Conventional metals such as steel, aluminum, and copper are widely used in construction, manufacturing, and electrical applications due to their strength, durability, and conductivity. Their well-understood properties make them reliable choices for everyday use, but ongoing innovations are expanding their potential in emerging technologies. Explore the rest of this article to discover how these metals impact various industries and what future developments may hold for your projects.

Table of Comparison

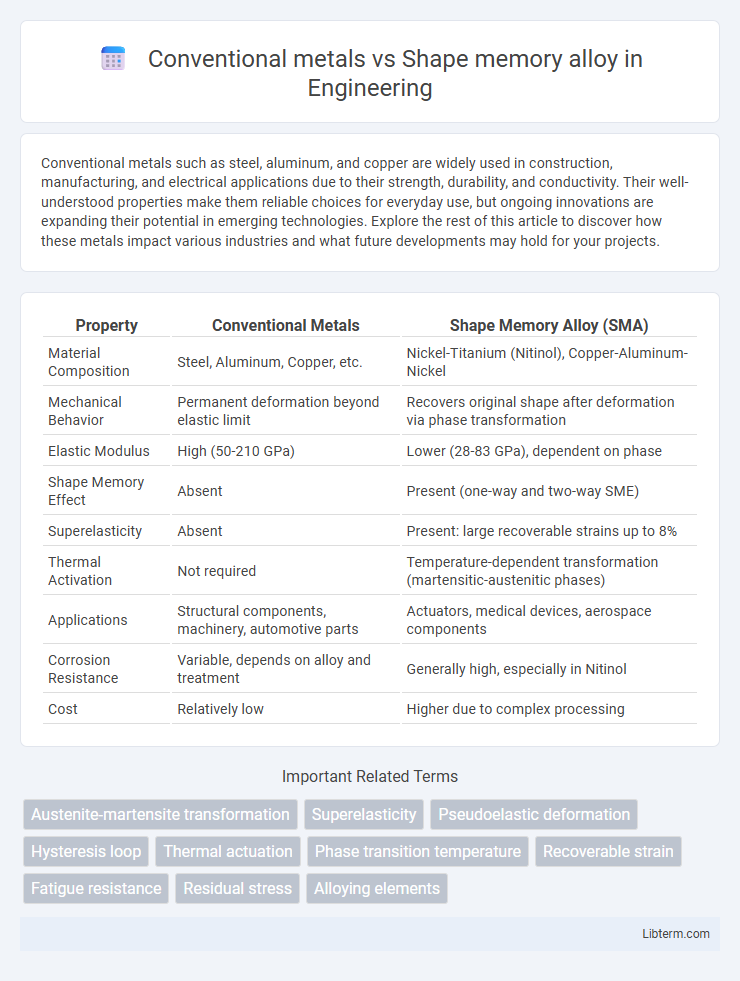

| Property | Conventional Metals | Shape Memory Alloy (SMA) |

|---|---|---|

| Material Composition | Steel, Aluminum, Copper, etc. | Nickel-Titanium (Nitinol), Copper-Aluminum-Nickel |

| Mechanical Behavior | Permanent deformation beyond elastic limit | Recovers original shape after deformation via phase transformation |

| Elastic Modulus | High (50-210 GPa) | Lower (28-83 GPa), dependent on phase |

| Shape Memory Effect | Absent | Present (one-way and two-way SME) |

| Superelasticity | Absent | Present: large recoverable strains up to 8% |

| Thermal Activation | Not required | Temperature-dependent transformation (martensitic-austenitic phases) |

| Applications | Structural components, machinery, automotive parts | Actuators, medical devices, aerospace components |

| Corrosion Resistance | Variable, depends on alloy and treatment | Generally high, especially in Nitinol |

| Cost | Relatively low | Higher due to complex processing |

Introduction to Conventional Metals and Shape Memory Alloys

Conventional metals such as steel, aluminum, and copper exhibit predictable elastic and plastic deformation under stress, making them fundamental materials in construction and manufacturing due to their strength, conductivity, and malleability. Shape Memory Alloys (SMAs), including nickel-titanium (Nitinol) and copper-based alloys, possess unique thermo-mechanical properties that allow them to return to a pre-deformed shape upon heating, enabling advanced applications in medical devices, aerospace, and robotics. The distinct phase transformation behavior of SMAs, driven by martensitic-austenitic transitions, contrasts with the dislocation mechanisms responsible for deformation in conventional metals, highlighting their specialized functionality.

Historical Development and Discovery

Conventional metals, such as steel and aluminum, have been used for centuries with their properties and applications extensively characterized through traditional metallurgy since ancient times. Shape memory alloys (SMAs), discovered in the 1930s with the identification of the unique phase transformation properties of Nitinol (nickel-titanium alloy) in the 1960s, introduced a revolutionary class of materials capable of returning to their original shape after deformation. The historical development of SMAs marks a significant advancement in materials science, shifting from simple mechanical behavior of conventional metals to smart materials with thermomechanical responsiveness.

Fundamental Properties Comparison

Conventional metals exhibit fixed mechanical properties such as elasticity, plasticity, and thermal conductivity, whereas shape memory alloys (SMAs) possess unique thermoelastic martensitic transformations that enable them to recover predefined shapes after deformation. SMAs demonstrate superelasticity and shape memory effects due to reversible phase changes between austenite and martensite, contrasting with the permanent deformation behavior of traditional metals under stress. Thermal hysteresis, transformation temperature ranges, and stress-strain characteristics distinctly differentiate SMAs from conventional metals in applications requiring adaptive and responsive material properties.

Mechanical Behavior and Performance

Conventional metals exhibit predictable elastic and plastic deformation with limited recovery after unloading, characterized by permanent shape changes under stress. Shape memory alloys (SMAs) demonstrate unique superelasticity and shape memory effects, allowing them to recover large strains through phase transformations between austenite and martensite phases. These phase-dependent behaviors of SMAs result in enhanced energy dissipation, self-healing capabilities, and improved fatigue resistance compared to traditional metals in mechanical applications.

Temperature Sensitivity and Memory Effect

Conventional metals exhibit limited temperature sensitivity, often losing mechanical strength or becoming brittle under extreme thermal conditions, whereas shape memory alloys (SMAs) uniquely respond to temperature changes by undergoing reversible phase transformations that enable the memory effect. SMAs, such as nickel-titanium (Nitinol), recover their original shape when heated above their transition temperature due to the martensite-to-austenite phase change, a phenomenon absent in conventional metals. This memory effect allows SMAs to perform self-healing and adaptive functions in temperature-variable environments, outperforming traditional metals in applications requiring thermal responsiveness.

Common Applications in Industry

Conventional metals like steel and aluminum are widely used in construction, automotive, and aerospace industries due to their high strength, durability, and cost-effectiveness. Shape memory alloys (SMAs), such as nickel-titanium (Nitinol), find specialized applications in medical devices, actuators, and robotics because of their unique ability to return to a predetermined shape after deformation. Industrial sectors utilize SMAs for temperature-sensitive valves, couplings, and adaptive structures, where conventional metals lack the functionality to respond dynamically to thermal or mechanical changes.

Advantages of Conventional Metals

Conventional metals offer superior mechanical strength and high tensile properties, making them ideal for structural applications requiring durability and load-bearing capacity. Their well-established manufacturing processes ensure cost-effectiveness and widespread availability, supporting mass production and diverse industrial uses. Furthermore, conventional metals exhibit predictable behavior under varying temperatures and stresses, providing reliability in traditional engineering environments.

Advantages of Shape Memory Alloys

Shape Memory Alloys (SMAs) offer superior flexibility by returning to their original shape after deformation, unlike conventional metals which undergo permanent plastic deformation. SMAs provide enhanced durability and stress resistance in dynamic applications such as aerospace and biomedical devices. Their ability to undergo phase transformation enables precise actuation and adaptive structures, making them ideal for advanced engineering solutions.

Limitations and Challenges

Conventional metals exhibit limitations such as permanent deformation under stress and lack of self-recovery, restricting their use in applications requiring high durability and adaptability. Shape memory alloys (SMAs) face challenges including higher material costs, complex manufacturing processes, and limited fatigue life due to phase transformation-induced stress. Both materials require advancements in corrosion resistance and mechanical stability to expand their application scope in aerospace, biomedical, and robotics industries.

Future Trends and Innovations

Shape memory alloys (SMAs) are revolutionizing industries with their unique ability to return to original shapes after deformation, offering superior performance compared to conventional metals in applications like aerospace and biomedical devices. Future trends involve integrating SMAs with advanced manufacturing techniques such as 3D printing to create more complex and efficient structures, enhancing energy efficiency and durability. Innovations in alloy composition and nanotechnology aim to improve the mechanical properties and temperature responsiveness of SMAs, positioning them as key materials in next-generation smart systems.

Conventional metals Infographic

libterm.com

libterm.com