Magnetic levitation uses magnetic forces to lift and propel objects without physical contact, reducing friction and enabling high-speed transportation and precise positioning. This technology is applied in maglev trains, contactless bearings, and advanced medical devices. Discover how magnetic levitation can revolutionize your understanding of motion and engineering in the full article.

Table of Comparison

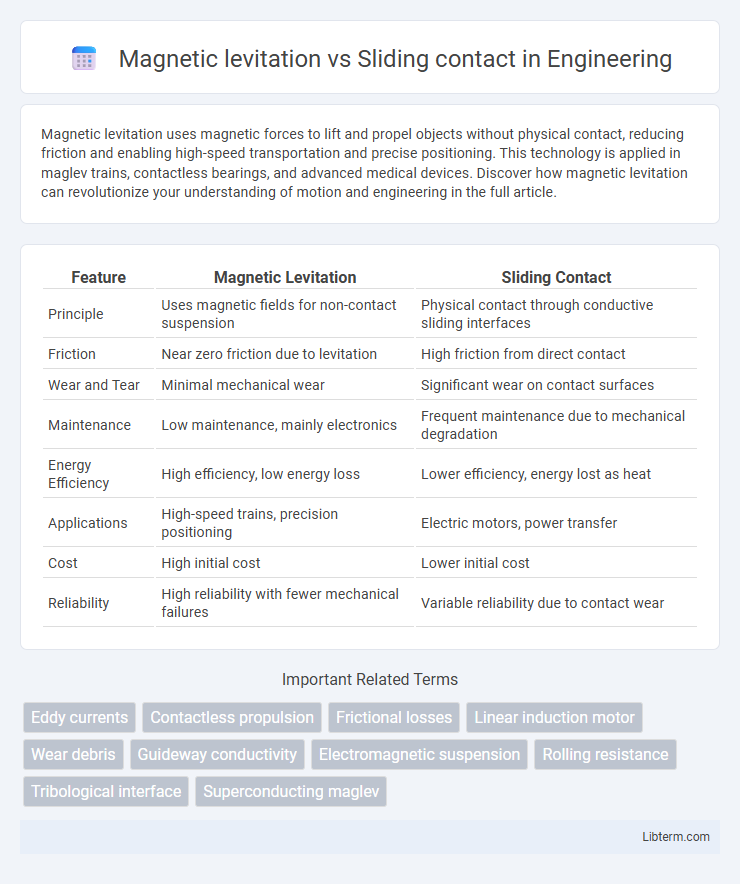

| Feature | Magnetic Levitation | Sliding Contact |

|---|---|---|

| Principle | Uses magnetic fields for non-contact suspension | Physical contact through conductive sliding interfaces |

| Friction | Near zero friction due to levitation | High friction from direct contact |

| Wear and Tear | Minimal mechanical wear | Significant wear on contact surfaces |

| Maintenance | Low maintenance, mainly electronics | Frequent maintenance due to mechanical degradation |

| Energy Efficiency | High efficiency, low energy loss | Lower efficiency, energy lost as heat |

| Applications | High-speed trains, precision positioning | Electric motors, power transfer |

| Cost | High initial cost | Lower initial cost |

| Reliability | High reliability with fewer mechanical failures | Variable reliability due to contact wear |

Introduction to Magnetic Levitation and Sliding Contact

Magnetic levitation (maglev) uses magnetic fields to lift and propel vehicles without physical contact, reducing friction and enabling high-speed transportation. Sliding contact systems rely on physical components like brushes or rails to transfer energy or movement, resulting in higher wear and maintenance. Maglev technology offers increased efficiency and durability compared to traditional sliding contact mechanisms in various industrial and transportation applications.

Fundamental Principles of Magnetic Levitation

Magnetic levitation operates on the fundamental principles of electromagnetic force, utilizing magnetic fields to lift and propel objects without physical contact, significantly reducing friction and wear. Sliding contact systems rely on direct mechanical interface, where motion is maintained through physical sliding components, leading to greater energy loss and increased maintenance. The core advantage of magnetic levitation lies in its ability to create stable, contactless support through repulsive and attractive magnetic forces governed by Maxwell's equations and the Lorentz force.

Mechanics of Sliding Contact Systems

Sliding contact systems rely on direct physical contact between moving surfaces, generating friction and wear that impacts mechanical efficiency and durability. Magnetic levitation eliminates physical contact by using magnetic fields to suspend and guide objects, significantly reducing mechanical resistance and maintenance needs. The mechanics of sliding contacts involve careful material selection and lubrication strategies to minimize friction and thermal degradation during motion.

Energy Efficiency Comparison

Magnetic levitation (maglev) systems exhibit higher energy efficiency than sliding contact mechanisms due to the elimination of direct frictional losses, resulting in reduced power consumption during operation. Maglev technology uses electromagnetic forces to suspend and propel vehicles, minimizing energy dissipation and enabling smoother acceleration with lower mechanical wear. In contrast, sliding contact systems generate considerable friction, causing energy loss as heat and increased maintenance demands, which decrease overall operational efficiency.

Wear and Maintenance Requirements

Magnetic levitation systems experience minimal wear due to the lack of physical contact between moving parts, significantly reducing maintenance requirements compared to sliding contact mechanisms. Sliding contact systems endure continuous friction, leading to component degradation and frequent replacement of brushes, bearings, or sliding surfaces. Consequently, magnetic levitation offers longer operational lifespan and lower downtime costs, making it a superior choice for applications demanding reliability and efficiency.

Speed and Performance Differences

Magnetic levitation trains achieve higher speeds compared to sliding contact systems by eliminating friction through magnetic suspension, allowing speeds exceeding 600 km/h with smoother acceleration and deceleration. Sliding contact trains rely on physical contact between wheels and rails, limiting maximum speeds to around 300 km/h due to friction and wear constraints, which also impact efficiency and maintenance frequency. The superior performance of magnetic levitation is evident in reduced vibration, lower energy consumption at high speeds, and enhanced ride comfort, making it ideal for ultra-fast rail transport.

Safety and Reliability Aspects

Magnetic levitation systems reduce mechanical wear and eliminate friction-related failures, enhancing overall safety and reliability compared to sliding contact technologies. The absence of physical contact minimizes contamination risks and decreases maintenance frequency, resulting in consistent performance and longer operational lifespans. In contrast, sliding contacts are prone to wear, sparking, and material degradation, which can compromise safety and increase downtime in industrial and transportation applications.

Applications in Modern Transportation

Magnetic levitation (maglev) technology enables high-speed trains to float above tracks, drastically reducing friction and allowing speeds exceeding 600 km/h, making it ideal for rapid transit and long-distance travel. Sliding contact systems, such as traditional railways and electric trams, rely on physical contact between wheels and rails, offering robust and cost-effective solutions for urban commuting and freight transport. Maglev's efficiency and low maintenance benefits modern transportation by minimizing wear and energy consumption, whereas sliding contact methods remain prevalent due to their established infrastructure and versatility across varied transit needs.

Environmental Impact Analysis

Magnetic levitation systems generate lower environmental impact by reducing friction and wear, which minimizes energy consumption and maintenance-related emissions compared to sliding contact mechanisms. Sliding contact technologies often rely on lubricants that can cause soil and water contamination over time, whereas magnetic levitation eliminates such risks through contactless operation. Overall, magnetic levitation offers a cleaner, more sustainable transportation solution by significantly lowering carbon footprints and environmental degradation.

Future Prospects and Technological Advancements

Magnetic levitation (maglev) offers significant future prospects due to its reduced friction, higher speeds, and lower maintenance compared to traditional sliding contact systems. Technological advancements in superconducting magnets and energy-efficient electromagnets are enhancing maglev train reliability and cost efficiency. In contrast, sliding contact technology benefits from incremental improvements in materials science and wear-resistant coatings but faces limitations in speed and scalability compared to maglev innovations.

Magnetic levitation Infographic

libterm.com

libterm.com