Takt time is a crucial metric in lean manufacturing that defines the pace at which products must be completed to meet customer demand. By calculating takt time, you can synchronize production processes, reduce waste, and improve overall efficiency. Discover how mastering takt time can transform your workflow by reading the rest of this article.

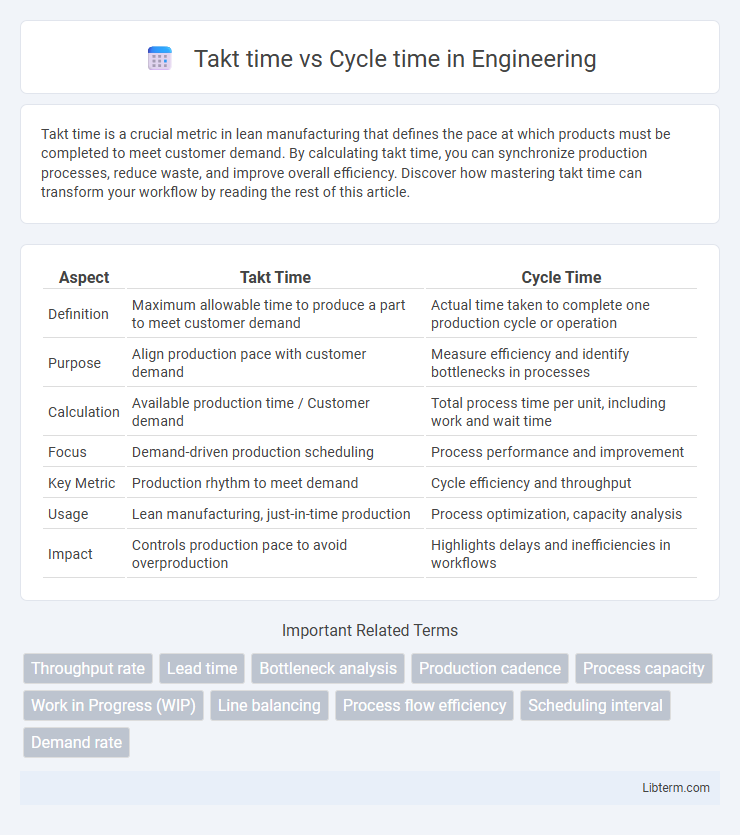

Table of Comparison

| Aspect | Takt Time | Cycle Time |

|---|---|---|

| Definition | Maximum allowable time to produce a part to meet customer demand | Actual time taken to complete one production cycle or operation |

| Purpose | Align production pace with customer demand | Measure efficiency and identify bottlenecks in processes |

| Calculation | Available production time / Customer demand | Total process time per unit, including work and wait time |

| Focus | Demand-driven production scheduling | Process performance and improvement |

| Key Metric | Production rhythm to meet demand | Cycle efficiency and throughput |

| Usage | Lean manufacturing, just-in-time production | Process optimization, capacity analysis |

| Impact | Controls production pace to avoid overproduction | Highlights delays and inefficiencies in workflows |

Understanding Takt Time and Cycle Time

Takt time represents the ideal pace at which products must be completed to meet customer demand, calculated by dividing available production time by customer demand units. Cycle time measures the actual time taken to complete one production cycle or process, revealing real operational efficiency. Comparing takt time to cycle time helps identify production bottlenecks and synchronize workflow to improve overall manufacturing productivity.

Key Differences Between Takt Time and Cycle Time

Takt time represents the rate at which products must be completed to meet customer demand, calculated by dividing available production time by customer demand. Cycle time measures the actual time taken to complete one unit of production from start to finish. The key difference lies in takt time setting the production pace to match demand, while cycle time reflects the real process capability and efficiency.

The Importance of Takt Time in Production

Takt time is crucial in production as it sets the pace by aligning manufacturing output with customer demand, ensuring efficiency and minimizing waste. Unlike cycle time, which measures the actual time taken to complete a task, takt time defines the ideal rhythm to meet market needs consistently. Maintaining takt time enhances workflow synchronization, reduces bottlenecks, and helps achieve lean manufacturing goals.

How to Calculate Cycle Time Accurately

Cycle time is calculated by measuring the total time taken to complete one unit of work from start to finish, including processing and waiting times. Accurate cycle time measurement requires timing multiple consecutive units to average out variations and excluding downtime unrelated to the actual task. Takt time, representing the customer demand rate, serves as a benchmark but differs from cycle time, which captures the real production pace for each unit.

Practical Applications of Takt Time

Takt time measures the rate at which products must be completed to meet customer demand, serving as a crucial metric in lean manufacturing for aligning production pace with sales. It helps streamline workflow by establishing a consistent rhythm, reducing waste, and preventing overproduction or bottlenecks. In practice, takt time enables production managers to allocate resources efficiently, schedule tasks realistically, and improve overall operational efficiency.

Cycle Time Reduction Strategies

Cycle time reduction strategies center on eliminating inefficiencies and streamlining workflows by implementing lean manufacturing principles, such as value stream mapping and continuous improvement (Kaizen). Techniques like workstation layout optimization, automation integration, and workforce training enhance process speed and consistency. Monitoring real-time data and applying Six Sigma methodologies further minimize variability and reduce cycle time, aligning production more closely with takt time requirements.

Aligning Takt Time with Customer Demand

Aligning takt time with customer demand ensures production processes meet real-time consumption rates, minimizing overproduction and inventory waste. Takt time represents the ideal pace to match customer demand, while cycle time measures the actual time taken to complete a task, highlighting process efficiency. Synchronizing cycle time with takt time enables manufacturers to streamline workflows, optimize resource allocation, and enhance overall operational performance.

Common Mistakes in Managing Cycle Time

Common mistakes in managing cycle time include confusing it with takt time, leading to misaligned production pacing and inefficiencies. Ignoring variability in cycle time prevents accurate forecasting and disrupts workflow synchronization. Failure to track cycle time consistently results in overlooked bottlenecks, reducing overall manufacturing productivity.

Benefits of Balancing Takt Time and Cycle Time

Balancing takt time and cycle time improves production efficiency by ensuring that manufacturing processes align with customer demand, minimizing inventory buildup and reducing lead times. Achieving harmony between these metrics enhances workflow consistency, prevents bottlenecks, and optimizes resource utilization on the production floor. This balance promotes operational stability and supports continuous improvement initiatives, leading to higher product quality and increased customer satisfaction.

Takt Time vs Cycle Time: Which Drives Efficiency?

Takt time represents the pace at which products must be completed to meet customer demand, while cycle time measures the actual time taken to complete one production process. Efficiency is primarily driven by aligning cycle time with takt time, as matching or reducing cycle time to takt time ensures production meets demand without delays or excess inventory. Continuous improvement in cycle time relative to takt time optimizes resource utilization and enhances overall manufacturing efficiency.

Takt time Infographic

libterm.com

libterm.com