Bainitic steel offers exceptional strength and toughness due to its unique microstructure formed through controlled heat treatment, making it ideal for demanding industrial applications. Its combination of hardness and ductility improves wear resistance and fatigue life, enhancing performance in automotive, aerospace, and heavy machinery components. Discover how bainitic steel can optimize your projects by exploring the detailed advantages and processing techniques in the rest of this article.

Table of Comparison

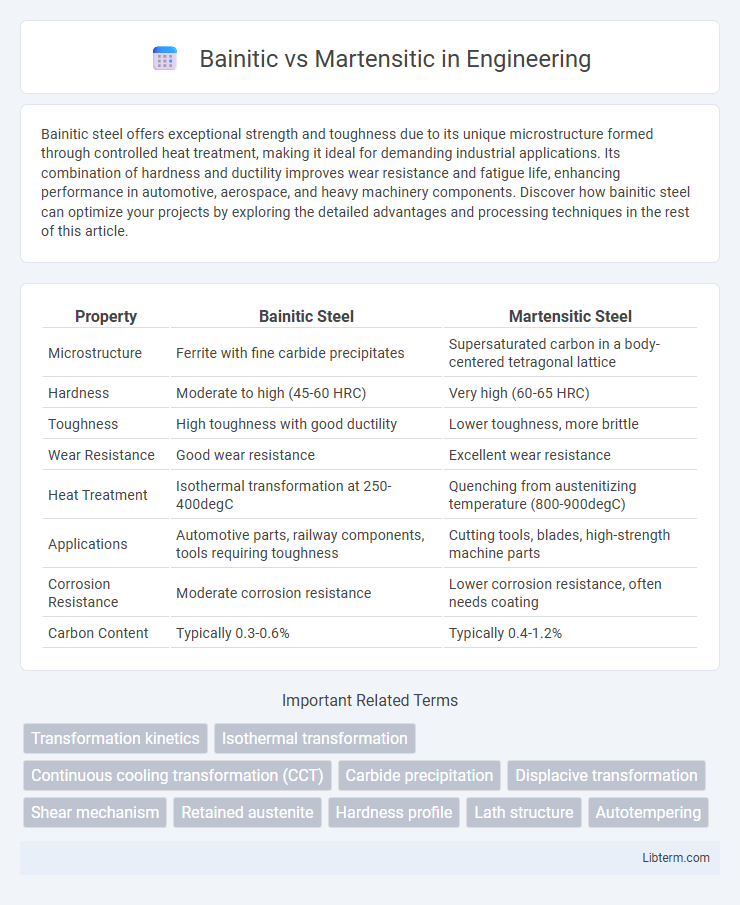

| Property | Bainitic Steel | Martensitic Steel |

|---|---|---|

| Microstructure | Ferrite with fine carbide precipitates | Supersaturated carbon in a body-centered tetragonal lattice |

| Hardness | Moderate to high (45-60 HRC) | Very high (60-65 HRC) |

| Toughness | High toughness with good ductility | Lower toughness, more brittle |

| Wear Resistance | Good wear resistance | Excellent wear resistance |

| Heat Treatment | Isothermal transformation at 250-400degC | Quenching from austenitizing temperature (800-900degC) |

| Applications | Automotive parts, railway components, tools requiring toughness | Cutting tools, blades, high-strength machine parts |

| Corrosion Resistance | Moderate corrosion resistance | Lower corrosion resistance, often needs coating |

| Carbon Content | Typically 0.3-0.6% | Typically 0.4-1.2% |

Introduction to Bainitic and Martensitic Structures

Bainitic structures form through isothermal transformation and consist of a fine microstructure combining ferrite and cementite, offering a balance between strength and toughness. Martensitic structures result from rapid quenching, producing a supersaturated, needle-like tetragonal phase of iron and carbon that is extremely hard but brittle. The primary difference lies in their formation mechanisms and resulting mechanical properties, influencing applications in wear-resistant and high-strength steel components.

Formation Mechanisms: Bainite vs Martensite

Bainite forms through a diffusional mechanism at temperatures typically between 250degC and 550degC, involving the transformation of austenite into a fine mixture of ferrite and cementite or carbide precipitates. Martensite, in contrast, forms via a diffusionless shear transformation occurring rapidly upon quenching austenite below the martensite start temperature (Ms), producing a supersaturated, body-centered tetragonal (BCT) structure. The key distinction lies in bainite's shear and diffusion-controlled process versus martensite's diffusionless, shear-dominant mechanism.

Microstructural Characteristics

Bainitic microstructures consist of fine, acicular ferrite and retained austenite, offering a combination of strength and toughness due to the diffusion-controlled transformation process. Martensitic microstructures are characterized by a supersaturated, body-centered tetragonal phase formed through a diffusionless, rapid quenching mechanism, resulting in high hardness and brittleness. The distinct differences in morphology and phase composition between bainite and martensite significantly influence their mechanical properties and applications in steels.

Mechanical Properties Comparison

Bainitic steel exhibits a balanced combination of high strength and good toughness due to its fine microstructure, making it more ductile and impact-resistant compared to martensitic steel. Martensitic steel offers superior hardness and tensile strength because of its body-centered tetragonal structure, but it tends to be more brittle and less ductile. The choice between bainitic and martensitic steels depends on the required mechanical performance, with bainite preferred for applications demanding toughness and martensite for applications requiring maximum hardness.

Heat Treatment Processes

Bainitic and martensitic microstructures form during different heat treatment processes that influence steel's mechanical properties. Bainite develops through an isothermal transformation by holding steel at intermediate temperatures (250-550degC), resulting in a tough and ductile microstructure. Martensite forms by rapid quenching from austenitizing temperature (above 800degC), producing a hard and brittle phase due to a diffusionless transformation.

Applications in Industry

Bainitic steel's combination of high strength and toughness makes it ideal for automotive components, wear-resistant tools, and rail tracks requiring durability under cyclic loading. Martensitic steel, known for its exceptional hardness and abrasion resistance, is widely used in cutting tools, aerospace parts, and medical instruments that demand precise dimensional stability. Both microstructures serve critical industrial roles, with bainite favored for balanced mechanical properties and martensite for extreme hardness applications.

Advantages and Limitations

Bainitic steel offers a superior combination of strength and toughness compared to martensitic steel, making it ideal for applications requiring resistance to impact and wear. Martensitic steel, characterized by its high hardness and excellent dimensional stability, provides superior strength but is more prone to brittleness and requires careful heat treatment to avoid cracking. The main limitation of bainitic steel lies in its relatively complex heat treatment process, while martensitic steel's lower toughness can limit its use in dynamic or high-impact environments.

Wear and Corrosion Resistance

Bainitic steel exhibits superior wear resistance due to its fine microstructure combining hardness with toughness, making it ideal for applications involving abrasive conditions. Martensitic steel, characterized by its high hardness from rapid quenching, provides excellent wear resistance but is more susceptible to brittleness and cracking under stress. Corrosion resistance in bainitic alloys often surpasses that of martensitic steels because of their more stable microstructure and lower residual stresses, which reduce susceptibility to environmental degradation.

Cost and Manufacturing Considerations

Bainitic steel offers a balance between cost-efficiency and mechanical performance, requiring lower cooling rates than martensitic steel, which reduces manufacturing complexity and energy consumption. Martensitic steel demands rapid quenching and precise thermal control, increasing production costs and necessitating advanced equipment for consistent hardness and strength. Overall, bainitic steel production is more cost-effective for large-scale manufacturing, while martensitic steel, despite higher costs, is preferred for applications requiring superior hardness and wear resistance.

Choosing Between Bainitic and Martensitic Steels

Choosing between bainitic and martensitic steels depends on the desired mechanical properties and application requirements. Bainitic steel offers a good balance of strength and toughness with improved wear resistance, ideal for components needing fatigue resistance and impact toughness. Martensitic steel provides higher hardness and tensile strength, making it suitable for applications requiring maximum hardness and wear resistance, such as cutting tools and wear-resistant parts.

Bainitic Infographic

libterm.com

libterm.com