Groove is a powerful tool designed to enhance your workflow by integrating communication, project management, and collaboration in one platform. Its intuitive interface helps teams stay organized, streamline tasks, and maintain seamless interaction, increasing overall productivity. Discover how Groove can transform your daily operations in the rest of this article.

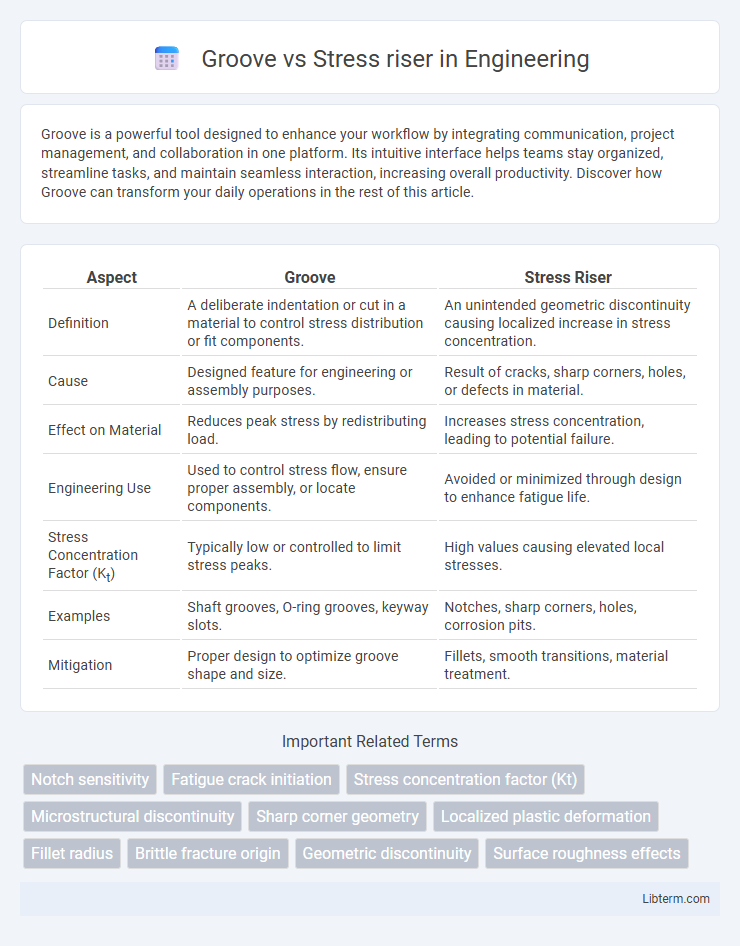

Table of Comparison

| Aspect | Groove | Stress Riser |

|---|---|---|

| Definition | A deliberate indentation or cut in a material to control stress distribution or fit components. | An unintended geometric discontinuity causing localized increase in stress concentration. |

| Cause | Designed feature for engineering or assembly purposes. | Result of cracks, sharp corners, holes, or defects in material. |

| Effect on Material | Reduces peak stress by redistributing load. | Increases stress concentration, leading to potential failure. |

| Engineering Use | Used to control stress flow, ensure proper assembly, or locate components. | Avoided or minimized through design to enhance fatigue life. |

| Stress Concentration Factor (Kt) | Typically low or controlled to limit stress peaks. | High values causing elevated local stresses. |

| Examples | Shaft grooves, O-ring grooves, keyway slots. | Notches, sharp corners, holes, corrosion pits. |

| Mitigation | Proper design to optimize groove shape and size. | Fillets, smooth transitions, material treatment. |

Introduction to Grooves and Stress Risers

Grooves and stress risers are critical features in material science and engineering that influence structural integrity and fatigue resistance. Grooves are deliberate indentations or channels designed into components to guide stress distribution or accommodate assembly, while stress risers are localized areas where stress concentration occurs, often leading to crack initiation and failure. Understanding the role of grooves and identifying stress risers enables engineers to optimize designs, enhance durability, and prevent premature material failure.

Definition and Key Differences

A groove is a longitudinal depression or channel in a material surface designed to guide or accommodate other components, while a stress riser is a localized geometric irregularity causing concentrated stress in materials under load. The key difference lies in their function and effect: grooves often serve practical mechanical purposes without significantly weakening the structure, whereas stress risers can initiate cracks or failures by amplifying stress at specific points. Understanding these distinctions is crucial for engineers to design components that balance functionality with structural integrity.

Causes of Groove Formation

Groove formation primarily results from repetitive mechanical stress or friction acting on a specific area, causing localized deformation or wear. In contrast, stress risers are typically caused by abrupt changes in material geometry such as notches, holes, or cracks that concentrate stress in a small region. The groove acts as a surface irregularity that increases the likelihood of crack initiation and propagation under cyclic loading conditions.

Factors Leading to Stress Risers

Stress risers develop due to abrupt changes in a material's geometry, such as grooves, notches, or holes, which concentrate stress in localized areas. These factors reduce the effective cross-sectional area and create points where cracks may initiate under cyclic loading or impact. Understanding how groove dimensions, shape, and placement influence stress concentration is critical for predicting material failure and improving design durability.

Impact on Material Strength

Grooves create intentional changes in the geometry of a material that can concentrate stress but also allow for controlled deformation, often enhancing fatigue resistance when designed properly. Stress risers, however, are unintentional irregularities such as sharp corners or surface defects that significantly weaken material strength by localizing stress and accelerating crack initiation. The impact on material strength is substantial, with stress risers causing premature failure while properly designed grooves can improve structural durability under cyclic loads.

Groove vs. Stress Riser: Mechanical Behavior

Groove and stress risers significantly influence the mechanical behavior of materials by altering stress distribution and concentration. Grooves typically reduce cross-sectional area, creating localized stress concentration that can initiate cracks under cyclic loading. Stress risers, such as notches or abrupt geometry changes, intensify stress locally, decreasing fatigue life and increasing the likelihood of failure in mechanical components.

Common Applications in Engineering

Grooves and stress risers are critical considerations in mechanical and structural engineering, impacting component longevity and performance. Grooves, commonly found in shafts and pulleys, are designed to accommodate seals, retain rings, or enable assembly features without concentrating stress. Stress risers, often occurring near holes, notches, or sudden changes in cross-section, are intentional or unavoidable geometric discontinuities that can significantly elevate localized stress, requiring careful analysis in fatigue-critical applications such as aerospace structures, bridges, and pressure vessels.

Prevention and Design Considerations

Groove and stress riser designs critically impact structural integrity by concentrating stress and causing potential failure points; prevention involves smooth transitions, rounded corners, and uniform material thickness to minimize stress concentration. Utilizing finite element analysis (FEA) during design phases identifies high-stress regions, enabling modifications such as filleting grooves and avoiding sharp edges that cause stress risers. Material selection and surface treatments also enhance fatigue resistance, ensuring durability in mechanical components subjected to cyclical loading.

Case Studies and Real-World Examples

Case studies of orthopedic implant failures highlight how grooves often act as initiation points for cracks due to stress concentration, causing fatigue fractures. Stress risers, such as notches or sharp transitions in implant design, have been shown in real-world examples to significantly reduce the fatigue life of metal components by amplifying localized stresses. Clinical reports document instances where implants with poorly designed grooves or stress risers led to premature mechanical failure, emphasizing the critical role of optimized geometry in enhancing the durability of biomedical devices.

Conclusion: Choosing Between Grooves and Stress Risers

Choosing between grooves and stress risers depends on the specific application and structural requirements, as grooves help guide crack propagation and reduce stress concentration, while stress risers intentionally localize stress to control material failure. Grooves are preferable in designs prioritizing durability and fatigue resistance, whereas stress risers are useful in controlled fracture mechanisms or load redistribution. Engineers must evaluate factors like load type, material properties, and failure modes to optimize performance using either grooves or stress risers effectively.

Groove Infographic

libterm.com

libterm.com