A turning pair, also known as a revolute joint, allows rotational motion between two connected components while restricting other degrees of freedom. This mechanical joint is commonly used in shafts, hinges, and robotic arms to enable precise angular movement. Explore the rest of the article to understand how turning pairs function and their applications in various mechanical systems.

Table of Comparison

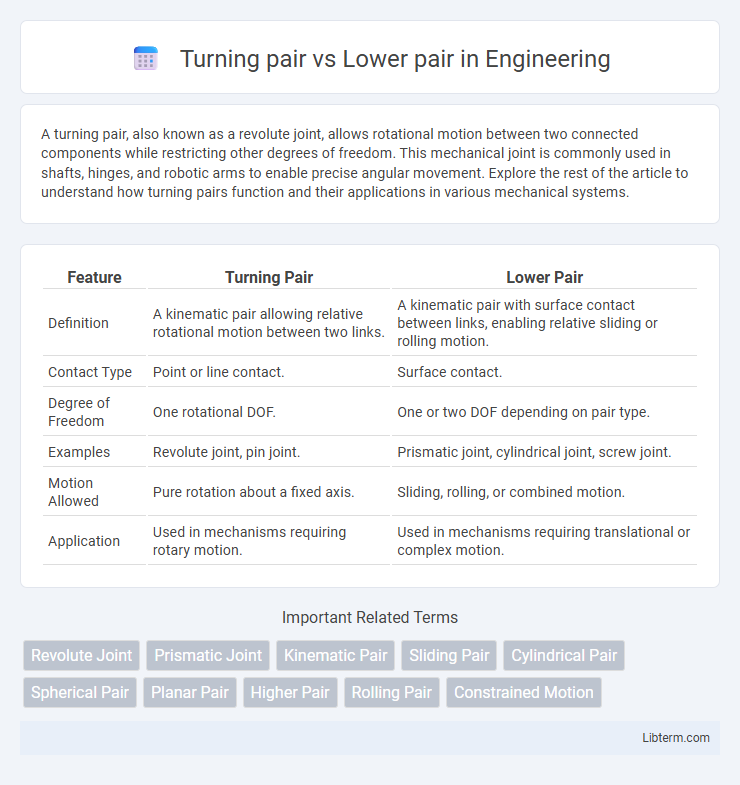

| Feature | Turning Pair | Lower Pair |

|---|---|---|

| Definition | A kinematic pair allowing relative rotational motion between two links. | A kinematic pair with surface contact between links, enabling relative sliding or rolling motion. |

| Contact Type | Point or line contact. | Surface contact. |

| Degree of Freedom | One rotational DOF. | One or two DOF depending on pair type. |

| Examples | Revolute joint, pin joint. | Prismatic joint, cylindrical joint, screw joint. |

| Motion Allowed | Pure rotation about a fixed axis. | Sliding, rolling, or combined motion. |

| Application | Used in mechanisms requiring rotary motion. | Used in mechanisms requiring translational or complex motion. |

Definition of Turning Pair and Lower Pair

A turning pair is a type of kinematic pair that allows relative rotational motion between two connected elements while restricting translational movement, commonly found in hinges and shafts. Lower pairs are mechanical joints characterized by surface contact between the mating elements, permitting constrained motion such as rotation or sliding; turning pairs are a subset of lower pairs specifically enabling rotation. Understanding the distinction between turning pairs and other lower pairs helps in designing mechanisms with precise motion control and minimal clearance.

Key Differences Between Turning Pair and Lower Pair

Turning pairs allow relative rotational motion between two links around a fixed axis, enabling mechanisms to transmit motion with angular displacement. Lower pairs, encompassing turning pairs as a subset, are characterized by surface contact between links, permitting relative motion that can include rotation or translation with higher contact area and better load distribution. The key difference lies in the type of motion allowed and contact nature: turning pairs enable purely rotational movement about a fixed axis, while lower pairs include any pair permitting relative motion through surface contact, such as sliding or rolling.

Fundamental Characteristics of Turning Pairs

Turning pairs are fundamental elements in kinematic chains characterized by one link rotating relative to another about a fixed axis, providing a single degree of rotational freedom. They exhibit features such as a cylindrical surface contact, constrained motion allowing only angular displacement, and minimal friction due to bearing-like behavior. Lower pairs encompass turning pairs but broadly include any pair with surface contact, whereas turning pairs exclusively emphasize rotational joints with one rotational degree of freedom around a fixed axis.

Essential Properties of Lower Pairs

Lower pairs are characterized by surface contact between their elements, enabling relative sliding or rolling motion with constrained degrees of freedom. Essential properties of lower pairs include a well-defined kinematic constraint, ensuring precise motion control and minimal play or backlash. Unlike turning pairs, which typically involve pin joints allowing rotation, lower pairs provide complex motion patterns through sustained surface engagement.

Types of Joints in Turning Pairs

Turning pairs in mechanical engineering primarily consist of lower pairs characterized by surface contact between two members, allowing relative rotational motion around a fixed axis. The main types of joints in lower pairs relevant to turning pairs include revolute joints, which facilitate rotation with one degree of freedom, and cylindrical joints, which combine rotation and sliding movements along the axis. These joints are critical in mechanisms such as hinges, pivots, and crankshafts where precise angular motion is required.

Types of Joints in Lower Pairs

Lower pairs consist of kinematic pairs with surface contact between elements, providing constrained motion such as turning, sliding, or rolling, and include revolute, prismatic, cylindrical, spherical, helical, and planar joints. Revolute (turning) joints allow relative rotational motion around a fixed axis, commonly found in hinges and shafts. Prismatic joints enable linear sliding motion, while cylindrical joints combine rotation and translation; spherical joints permit three degrees of rotational freedom, helical joints allow combined rotation and translation like screws, and planar joints facilitate two-dimensional sliding.

Mechanical Applications of Turning Pairs

Turning pairs, a fundamental class of kinematic pairs, enable rotational motion between two connected components, commonly found in hinges, shafts, and rotating joints in engines and turbines. Mechanical applications of turning pairs ensure smooth angular displacement with low friction and high precision, critical for devices like robotic arms, gear assemblies, and crankshafts. In contrast, lower pairs involve surface contact with higher constraints, but turning pairs specifically optimize rotational movement to enhance efficiency and durability in mechanical systems.

Common Uses of Lower Pairs in Mechanisms

Lower pairs, characterized by surface contact between elements such as revolute, prismatic, and screw pairs, are widely used in mechanisms requiring precise motion control, like robotic arms, linkages, and vehicle suspensions. These pairs facilitate smooth rotational or sliding motion, making them essential in engines, crankshafts, and cam-follower systems. Turning pairs, a subset of lower pairs involving pure rotational motion around a fixed axis, are crucial in applications like hinges, gears, and rotary shafts where continuous rotation is needed.

Advantages and Limitations of Turning vs Lower Pairs

Turning pairs offer precise rotational motion with minimal friction, ideal for components like hinges and shafts requiring smooth angular displacement. Lower pairs, defined by surface contact such as sliding or rolling, provide varied movement types but may result in higher wear and friction compared to turning pairs. The main limitation of turning pairs is their restriction to rotational motion around a fixed axis, whereas lower pairs allow more complex relative motion but often at the cost of reduced efficiency and increased maintenance.

Practical Examples Comparing Turning and Lower Pairs

Turning pairs, characterized by rotary motion between elements such as a hinge or crankshaft, are exemplified in door hinges and engine crankpins, enabling rotational movement around a fixed axis. Lower pairs, including both turning pairs and sliding pairs, involve surface contact and constrain motion to a single degree of freedom; examples include the piston-cylinder assembly in engines, which permits sliding motion, and the revolute joint in robotic arms. Comparing these, turning pairs primarily facilitate rotation with minimal friction, whereas lower pairs encompass various contact types enabling controlled motion paths in mechanical linkages and machines.

Turning pair Infographic

libterm.com

libterm.com