Case hardening is a heat treatment process that enhances the surface hardness of metal parts while maintaining a softer, ductile interior. This technique improves wear resistance and fatigue strength, making components like gears and shafts more durable under stress. Explore the rest of the article to understand how case hardening can extend the life and performance of your mechanical parts.

Table of Comparison

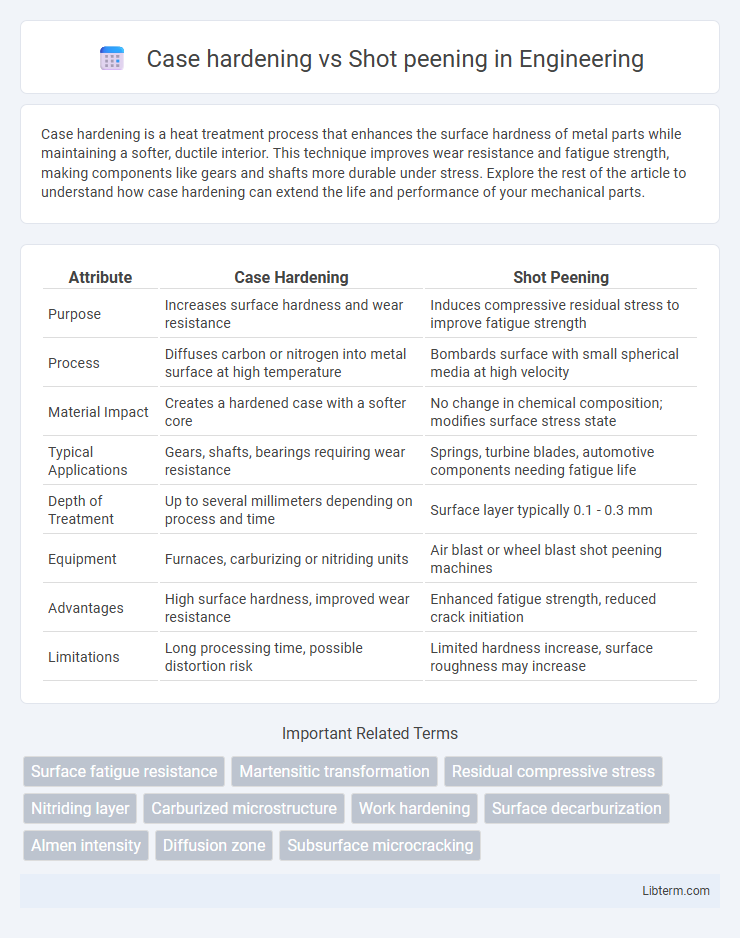

| Attribute | Case Hardening | Shot Peening |

|---|---|---|

| Purpose | Increases surface hardness and wear resistance | Induces compressive residual stress to improve fatigue strength |

| Process | Diffuses carbon or nitrogen into metal surface at high temperature | Bombards surface with small spherical media at high velocity |

| Material Impact | Creates a hardened case with a softer core | No change in chemical composition; modifies surface stress state |

| Typical Applications | Gears, shafts, bearings requiring wear resistance | Springs, turbine blades, automotive components needing fatigue life |

| Depth of Treatment | Up to several millimeters depending on process and time | Surface layer typically 0.1 - 0.3 mm |

| Equipment | Furnaces, carburizing or nitriding units | Air blast or wheel blast shot peening machines |

| Advantages | High surface hardness, improved wear resistance | Enhanced fatigue strength, reduced crack initiation |

| Limitations | Long processing time, possible distortion risk | Limited hardness increase, surface roughness may increase |

Introduction to Surface Hardening Techniques

Surface hardening techniques improve wear resistance by altering the material's surface properties while maintaining a tough core. Case hardening involves diffusing carbon or nitrogen into the steel surface through processes like carburizing or nitriding, resulting in a hard outer layer. Shot peening uses high-velocity spherical media to induce compressive stresses, enhancing fatigue strength without changing the chemical composition.

What is Case Hardening?

Case hardening is a heat treatment process that enhances the surface hardness of metal parts while maintaining a softer, ductile core, improving wear resistance and fatigue strength. It involves carburizing, nitriding, or carbonitriding the outer layer to introduce carbon or nitrogen, thereby creating a hardened case. This method is commonly used in manufacturing gears, bearings, and automotive components where surface durability and core toughness are critical.

Process Overview: Case Hardening Methods

Case hardening methods primarily include carburizing, nitriding, and carbonitriding, each altering the surface chemistry of steel to improve hardness while maintaining a softer, ductile core. Carburizing involves heating the steel in a carbon-rich environment, allowing carbon atoms to diffuse into the surface and form a hardened layer. Nitriding uses nitrogen diffusion at lower temperatures for precise surface hardening, whereas shot peening mechanically induces compressive stresses by bombarding the surface with small spherical media, enhancing fatigue resistance without changing the chemical composition.

What is Shot Peening?

Shot peening is a mechanical surface treatment process that uses small spherical media to bombard a metal surface, inducing compressive residual stresses that enhance fatigue strength and resistance to stress corrosion cracking. Unlike case hardening, which alters the metal's surface composition through heat treatment, shot peening strengthens the surface by mechanically deforming it without changing its chemical properties. This process is widely utilized in aerospace, automotive, and heavy machinery industries to extend component life and improve durability.

How Shot Peening Works

Shot peening works by bombarding the metal surface with small spherical media called shots, creating compressive residual stresses that enhance fatigue strength and resistance to cracking. This process induces plastic deformation on the surface layer without altering the core material, leading to improved durability and resistance to stress-corrosion cracking. Unlike case hardening, which involves diffusion of carbon or nitrogen into the metal surface to increase hardness, shot peening primarily improves mechanical properties through mechanical work hardening and surface stress modification.

Key Differences Between Case Hardening and Shot Peening

Case hardening enhances surface hardness by infusing carbon or nitrogen into the metal's outer layer to improve wear resistance, while shot peening induces compressive residual stress through bombarding the surface with small spherical media to increase fatigue strength. The case hardening process chemically alters the surface composition, creating a hardened case over a tough core, whereas shot peening mechanically modifies the surface texture without changing its chemical makeup. Key differences include the depth of effect, with case hardening producing a deeper hardened layer and shot peening providing a thin, stress-induced surface layer.

Applications: When to Use Case Hardening

Case hardening is ideal for applications requiring a tough core with a wear-resistant surface, such as automotive gears, camshafts, and bearing races. It enhances surface hardness while maintaining core toughness, making it suitable for parts subjected to high contact stress and fatigue. Use case hardening when components demand a durable surface to resist abrasion without compromising overall strength.

Applications: When to Use Shot Peening

Shot peening is ideal for applications requiring enhanced fatigue strength, such as aerospace components, automotive parts, and heavy machinery subjected to cyclic stresses. It induces compressive surface stresses that improve resistance to crack initiation and propagation without altering core hardness, making it suitable for parts that need surface durability along with a tough core. Unlike case hardening, which diffuses carbon or nitrogen to harden the surface, shot peening is preferred when the objective is to relieve tensile stresses and extend the lifespan of components exposed to high fatigue loads.

Advantages and Limitations of Each Method

Case hardening enhances surface hardness by infusing carbon or nitrogen into steel, improving wear resistance and fatigue strength, but it may cause dimensional distortion and requires precise temperature control. Shot peening induces compressive surface stress through controlled impacts of small spherical media, effectively increasing fatigue life and resistance to stress corrosion cracking, though it demands careful parameter adjustment to avoid surface damage or over-peening. Both methods extend component lifespan in critical applications, with case hardening suited for improved surface durability and shot peening optimal for residual stress management.

Choosing the Right Surface Hardening Process

Choosing the right surface hardening process depends on the application's wear resistance, fatigue strength, and dimensional accuracy requirements. Case hardening provides a hard, wear-resistant outer layer ideal for components like gears and crankshafts, while shot peening enhances fatigue strength by inducing beneficial compressive stresses on surfaces prone to cyclic loading. Understanding each method's impact on material properties and operational conditions ensures optimal performance and longevity of mechanical parts.

Case hardening Infographic

libterm.com

libterm.com