Dovetail joints offer exceptional strength and durability in woodworking by interlocking wedge-shaped pins and tails, ensuring a secure fit without the need for nails or screws. This technique is often used in cabinetry and drawer construction to provide long-lasting stability and an aesthetically pleasing finish. Explore the rest of this article to master the art of creating dovetail joints and enhance your woodworking projects.

Table of Comparison

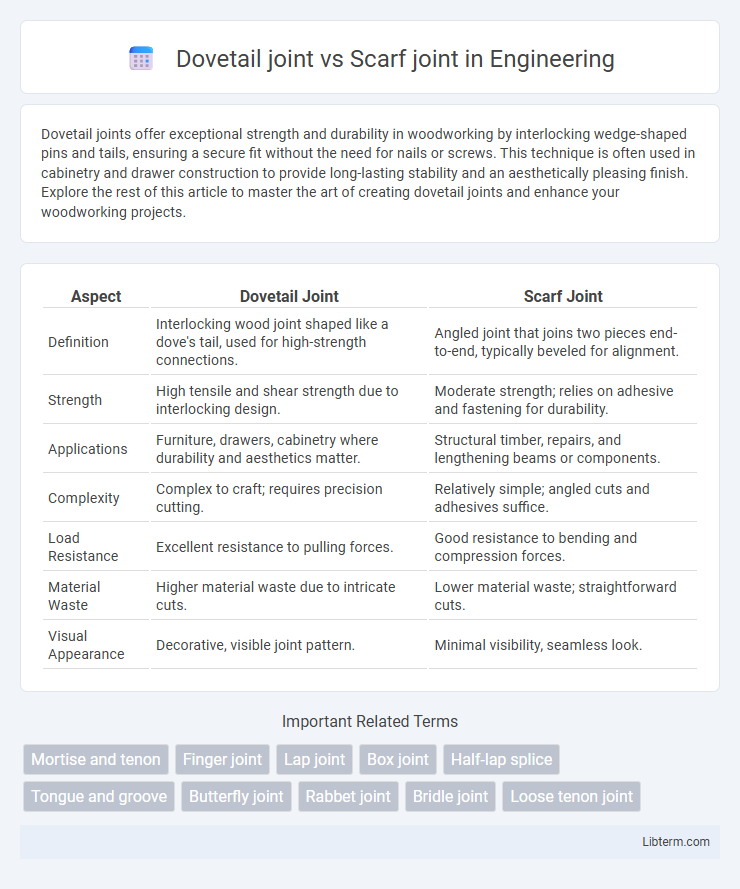

| Aspect | Dovetail Joint | Scarf Joint |

|---|---|---|

| Definition | Interlocking wood joint shaped like a dove's tail, used for high-strength connections. | Angled joint that joins two pieces end-to-end, typically beveled for alignment. |

| Strength | High tensile and shear strength due to interlocking design. | Moderate strength; relies on adhesive and fastening for durability. |

| Applications | Furniture, drawers, cabinetry where durability and aesthetics matter. | Structural timber, repairs, and lengthening beams or components. |

| Complexity | Complex to craft; requires precision cutting. | Relatively simple; angled cuts and adhesives suffice. |

| Load Resistance | Excellent resistance to pulling forces. | Good resistance to bending and compression forces. |

| Material Waste | Higher material waste due to intricate cuts. | Lower material waste; straightforward cuts. |

| Visual Appearance | Decorative, visible joint pattern. | Minimal visibility, seamless look. |

Introduction to Wood Joinery Techniques

Dovetail joints provide superior strength and resistance to pulling forces by interlocking wedge-shaped pins and tails, making them ideal for drawers and boxes. Scarf joints connect two wood pieces end-to-end with angled cuts, used mainly to extend wood length in beams or moldings while maintaining alignment. Both techniques are fundamental in wood joinery, enhancing structural integrity and aesthetic appeal in furniture and construction projects.

What is a Dovetail Joint?

A dovetail joint is a woodworking technique characterized by interlocking wedge-shaped pins and tails that provide exceptional tensile strength and resistance to pulling apart. Commonly used in drawer construction and fine cabinetry, this joint offers both structural integrity and aesthetic appeal due to its distinctive fan-shaped pattern. Unlike the scarf joint, which primarily joins two pieces end-to-end, the dovetail joint excels in connecting boards at right angles for durable corner assemblies.

What is a Scarf Joint?

A scarf joint is a woodworking technique used to join two pieces of timber end-to-end by tapering and overlapping the ends, creating an extended and strong connection often used in lengthening beams or repairing damaged wood. Unlike the dovetail joint, which interlocks angled tails and pins for lateral strength, the scarf joint relies on the bonded surface area and adhesive or mechanical fasteners to maintain structural integrity under tension or compression. This joint is especially valuable in construction and boatbuilding for achieving smooth, continuous lines without visible end grain disruptions.

Historical Applications of Dovetail and Scarf Joints

Dovetail joints have been historically prized in fine woodworking and cabinetry due to their exceptional tensile strength and resistance to pulling apart, evident in ancient Egyptian and Chinese artifacts dating back thousands of years. Scarf joints, meanwhile, were traditionally employed in shipbuilding and timber framing to join two pieces of wood end-to-end, enabling the construction of longer beams essential for large ships and historic wooden structures like medieval cathedrals. The enduring use of dovetail joints in furniture and scarf joints in architectural timberwork highlights their specialized roles shaped by centuries of craftsmanship and structural necessity.

Structural Strength: Dovetail vs Scarf Joint

Dovetail joints exhibit superior structural strength compared to scarf joints due to their interlocking design, which resists tension and shear forces effectively, making them ideal for high-load applications in furniture and cabinetry. Scarf joints, while providing a long surface area for adhesive bonding, rely primarily on glue strength and proper alignment, resulting in lower mechanical resistance under stress. The inherent mechanical interlock in dovetail joints distributes stresses more evenly, significantly enhancing durability and longevity over scarf joints in structural woodworking.

Aesthetic Differences Between Dovetail and Scarf Joints

Dovetail joints exhibit a distinctive, interlocking pattern that enhances visual appeal and showcases craftsmanship through their contrasting wedge-shaped pins and tails. In contrast, scarf joints present a more subtle, elongated seam that prioritizes continuity and minimal disruption of the grain, offering a sleek and seamless look. The aesthetic choice between dovetail and scarf joints often depends on the desired balance between decorative detail and understated elegance in woodworking projects.

Tools and Skills Required for Each Joint

Creating a dovetail joint demands precision tools such as dovetail saws, chisels, and marking gauges, alongside advanced woodworking skills to achieve interlocking angled cuts that ensure strong mechanical strength. In contrast, a scarf joint requires more straightforward tools like hand saws, planes, and clamps, with moderate skill levels focused on creating clean, angled end surfaces for seamless wood lengthening. Mastery of the dovetail joint significantly enhances joinery aesthetics and durability, whereas the scarf joint prioritizes length extension and structural alignment.

Common Uses in Modern Woodworking

Dovetail joints are commonly used in drawer construction and fine cabinetry due to their exceptional tensile strength and resistance to pulling apart. Scarf joints find frequent application in lengthening wood components such as beams and moldings, where a seamless and strong connection is required along the grain. Modern woodworking often employs dovetail joints for visible, decorative corners, while scarf joints are preferred in structural repairs and extending timber in furniture making.

Pros and Cons: Dovetail Joint vs Scarf Joint

Dovetail joints offer exceptional tensile strength and resistance to pulling forces, making them ideal for drawer construction and fine woodworking, though they require skilled craftsmanship and precise cutting. Scarf joints provide a smooth, elongated surface for joining two pieces of wood end-to-end, beneficial in lengthening timber or repairing, but they generally lack the mechanical interlocking strength of dovetail joints and often rely on adhesives or fasteners for stability. Choosing between dovetail and scarf joints depends on the structural demand and aesthetic priorities of the woodworking project.

Which Joint Should You Choose?

Choose a dovetail joint when maximum strength, durability, and resistance to pulling forces are required, as its interlocking design provides superior mechanical stability ideal for drawer construction and fine cabinetry. Opt for a scarf joint to achieve a smooth, continuous appearance in long wood pieces, especially when joining beams or molding, prioritizing seamless alignment over load-bearing capacity. Consider the specific application, load requirements, and aesthetic goals to determine whether the robust dovetail or the sleek scarf joint best suits your woodworking project.

Dovetail joint Infographic

libterm.com

libterm.com