Non-contact technology revolutionizes interactions by eliminating the need for physical touch, enhancing hygiene and convenience in various applications such as payments, access control, and health monitoring. This approach reduces the risk of contamination, making it ideal for public settings and personal device use. Discover how non-contact solutions can transform your daily experience by reading the full article.

Table of Comparison

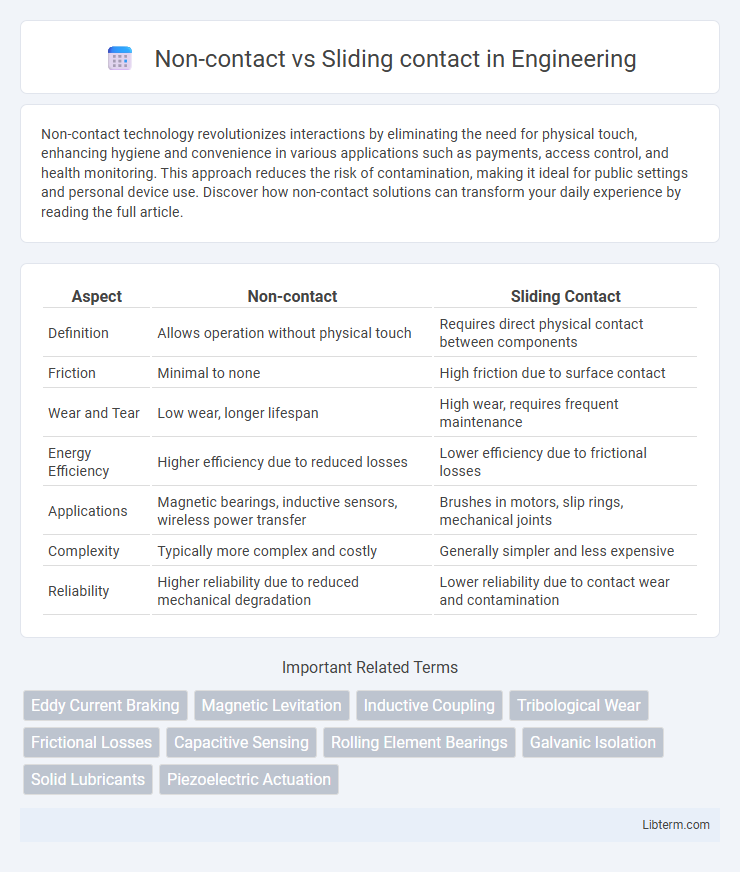

| Aspect | Non-contact | Sliding Contact |

|---|---|---|

| Definition | Allows operation without physical touch | Requires direct physical contact between components |

| Friction | Minimal to none | High friction due to surface contact |

| Wear and Tear | Low wear, longer lifespan | High wear, requires frequent maintenance |

| Energy Efficiency | Higher efficiency due to reduced losses | Lower efficiency due to frictional losses |

| Applications | Magnetic bearings, inductive sensors, wireless power transfer | Brushes in motors, slip rings, mechanical joints |

| Complexity | Typically more complex and costly | Generally simpler and less expensive |

| Reliability | Higher reliability due to reduced mechanical degradation | Lower reliability due to contact wear and contamination |

Introduction to Non-contact and Sliding Contact

Non-contact systems operate without physical interaction between surfaces, relying on magnetic, optical, or capacitive principles to measure motion or transmit signals, reducing wear and friction. Sliding contact systems involve direct contact between surfaces, often using brushes or sliding rings to maintain electrical continuity or mechanical motion, which can result in wear and maintenance requirements. Understanding these fundamental differences is crucial for selecting appropriate technology in applications ranging from sensors to electrical slip rings.

Definition and Basic Principles

Non-contact systems operate without physical touch between moving parts, relying on magnetic, optical, or electromagnetic fields to transfer energy or signals, thus minimizing wear and friction. Sliding contact involves direct physical interaction where two surfaces move relative to each other, commonly found in electrical brushes or mechanical bearings, resulting in friction and potential material degradation. The fundamental principle of non-contact technology is to maintain a gap that allows transfer through fields or waves, whereas sliding contact depends on continuous physical connection for energy or signal conduction.

Key Differences Between Non-contact and Sliding Contact

Non-contact methods rely on electromagnetic, optical, or inductive principles to measure or detect without physical touch, minimizing wear and friction, while sliding contact involves direct physical interaction between surfaces, often leading to wear and lubrication needs. Non-contact techniques provide higher precision and reduce maintenance compared to sliding contact systems, which may suffer from signal interference and mechanical degradation over time. Key differences include measurement accuracy, durability, maintenance requirements, and applications in environments sensitive to contamination or mechanical stress.

Types of Non-contact Mechanisms

Non-contact mechanisms include magnetic levitation, electrostatic, and aerodynamic bearings, which eliminate friction by avoiding direct physical contact between moving parts. Magnetic bearings use magnetic fields to support loads and enable smooth, precise motion with minimal wear and maintenance. Electrostatic bearings rely on electrostatic forces to achieve suspension, while aerodynamic bearings use a thin air film for support, both providing high-speed, low-friction operation in various industrial applications.

Types of Sliding Contact Mechanisms

Sliding contact mechanisms include plain bearings, journal bearings, and linear guides, where surfaces directly touch, causing friction and wear. Types vary by motion direction and load, such as rotary sliding in journal bearings or linear sliding in block-and-rail guides. Non-contact mechanisms like magnetic or air bearings eliminate physical contact by using magnetic fields or air films, reducing friction and maintenance.

Advantages of Non-contact Systems

Non-contact systems offer advantages such as reduced wear and tear, leading to longer component lifespan and lower maintenance costs compared to sliding contact systems. Their lack of physical friction enables higher precision and reliability in measurements and operations. These systems also provide better resistance to contamination and environmental factors, enhancing overall performance and durability.

Advantages of Sliding Contact Systems

Sliding contact systems offer superior electrical conductivity and reliability by maintaining continuous physical contact between components, minimizing signal loss and resistance. These systems demonstrate enhanced durability under high-load conditions and extreme environments due to robust material design and effective heat dissipation. Their simple construction reduces maintenance complexity and improves operational lifespan compared to non-contact alternatives such as inductive or capacitive couplers.

Limitations and Challenges

Non-contact sensors often face limitations in accuracy over long distances and susceptibility to environmental interference such as dust, moisture, or electromagnetic noise. Sliding contact systems encounter challenges including wear and tear, friction-induced signal degradation, and maintenance requirements due to physical contact between components. Both methods require careful consideration of application-specific conditions to balance precision, durability, and operational reliability.

Common Applications in Industry

Non-contact sensors are widely used in industries requiring precision and minimal wear, such as semiconductor manufacturing, robotics, and medical device production, where detecting position or proximity without physical interference is critical. Sliding contact sensors dominate applications in heavy machinery, automotive systems, and industrial automation where durability and reliable electrical connections are necessary despite constant movement and friction. Both sensor types play vital roles in optimizing performance and maintenance schedules across sectors including manufacturing, aerospace, and energy production.

Future Trends and Innovations

Non-contact technologies such as magnetic levitation and ultrasonic sensing are advancing rapidly, offering reduced friction, wear, and maintenance compared to traditional sliding contact systems. Innovations in smart materials and integrated sensors enable real-time monitoring and adaptive control for improved efficiency and lifespan in both non-contact and sliding contact applications. Emerging trends emphasize energy-efficient designs and hybrid systems that combine the reliability of sliding contacts with the precision of non-contact methods for future industrial and automotive uses.

Non-contact Infographic

libterm.com

libterm.com