Quenching is a crucial heat treatment process used to rapidly cool metals, enhancing their hardness and strength by transforming their microstructure. This technique is essential for improving wear resistance and durability in various industrial applications. Discover how quenching can optimize your metalworking projects by reading the full article.

Table of Comparison

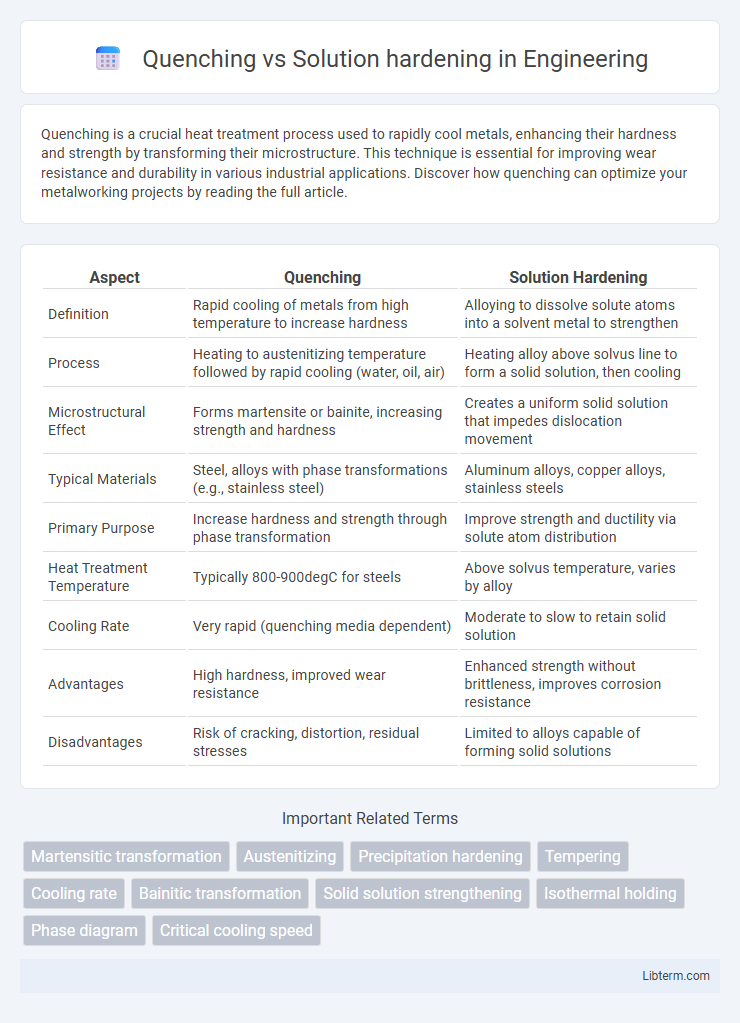

| Aspect | Quenching | Solution Hardening |

|---|---|---|

| Definition | Rapid cooling of metals from high temperature to increase hardness | Alloying to dissolve solute atoms into a solvent metal to strengthen |

| Process | Heating to austenitizing temperature followed by rapid cooling (water, oil, air) | Heating alloy above solvus line to form a solid solution, then cooling |

| Microstructural Effect | Forms martensite or bainite, increasing strength and hardness | Creates a uniform solid solution that impedes dislocation movement |

| Typical Materials | Steel, alloys with phase transformations (e.g., stainless steel) | Aluminum alloys, copper alloys, stainless steels |

| Primary Purpose | Increase hardness and strength through phase transformation | Improve strength and ductility via solute atom distribution |

| Heat Treatment Temperature | Typically 800-900degC for steels | Above solvus temperature, varies by alloy |

| Cooling Rate | Very rapid (quenching media dependent) | Moderate to slow to retain solid solution |

| Advantages | High hardness, improved wear resistance | Enhanced strength without brittleness, improves corrosion resistance |

| Disadvantages | Risk of cracking, distortion, residual stresses | Limited to alloys capable of forming solid solutions |

Introduction to Quenching and Solution Hardening

Quenching involves rapidly cooling a metal, typically steel, from a high temperature to lock its microstructure into a hard, martensitic phase, enhancing hardness and strength. Solution hardening, or solid solution strengthening, achieves increased strength by dissolving alloying elements uniformly in the metal matrix, causing lattice distortions that impede dislocation movement. Both techniques modify the microstructure but differ fundamentally in process and resulting mechanical properties.

Understanding Heat Treatment Processes

Quenching rapidly cools metals from high temperatures, creating a hard, brittle microstructure called martensite by trapping carbon atoms in solution. Solution hardening, or solid solution strengthening, involves dissolving alloying elements into the metal matrix to distort the lattice and impede dislocation movement, enhancing strength without rapid cooling. Both processes alter the microstructure through controlled heating and cooling cycles, optimizing mechanical properties for specific engineering applications.

Fundamentals of Quenching

Quenching is a rapid cooling process that transforms austenite into martensite, significantly increasing the hardness and strength of steel through a diffusionless phase transformation. The fundamentals of quenching involve controlling cooling rates and medium selection, typically water, oil, or air, to avoid defects such as cracking or distortion while achieving the desired microstructure. Unlike solution hardening, which relies on atomic size differences to impede dislocation movement, quenching fundamentally alters the phase of the metal to enhance mechanical properties.

Fundamentals of Solution Hardening

Solution hardening strengthens alloys by dissolving alloying elements into a solvent metal, creating a solid solution that impedes dislocation movement through lattice distortions. Unlike quenching, which rapidly cools materials to trap microstructures, solution hardening relies on atomic-scale interactions and the uniform distribution of solute atoms for enhanced mechanical properties. The effectiveness of solution hardening depends on the size difference between solute and solvent atoms, concentration of alloying elements, and temperature stability to maintain a supersaturated solid solution.

Key Differences Between Quenching and Solution Hardening

Quenching involves rapid cooling of a metal from a high temperature to lock in a hard microstructure, typically martensite in steels, enhancing hardness and strength. Solution hardening, or solid solution strengthening, introduces alloying elements into the metal's crystal lattice, creating lattice distortions that impede dislocation movement and increase strength without phase transformation. The critical difference lies in quenching being a heat treatment process altering microstructure via rapid cooling, while solution hardening is a compositional strengthening method relying on alloying element distribution within the solid solution.

Applications of Quenching in Industry

Quenching is widely used in the automotive and aerospace industries to increase the hardness and strength of steel components like gears, crankshafts, and turbine blades by rapid cooling from high temperatures. This process enhances wear resistance and fatigue life, making parts more durable under demanding operational conditions. Unlike solution hardening, which relies on alloying elements dissolved in a matrix, quenching achieves mechanical improvements through controlled thermal treatment and phase transformations.

Applications of Solution Hardening in Industry

Solution hardening is widely applied in the aerospace and automotive industries due to its ability to enhance corrosion resistance and mechanical strength in aluminum and titanium alloys. This process improves the durability and performance of structural components, such as aircraft frames and engine parts, by dissolving alloying elements uniformly within the metal matrix. These enhancements are critical for parts subjected to high stress and temperature fluctuations, ensuring longer service life and reliability.

Advantages and Disadvantages of Quenching

Quenching offers rapid cooling that enhances hardness and strength by transforming austenite into martensite, but it can introduce residual stresses and increase the risk of cracking or distortion. This process is advantageous for achieving high hardness levels but often requires subsequent tempering to improve toughness and reduce brittleness. Compared to solution hardening, quenching is more suitable for steels and some alloys needing quick strengthening but less effective for materials that rely on uniform solid solution formation.

Advantages and Disadvantages of Solution Hardening

Solution hardening increases the strength and corrosion resistance of alloys by dissolving alloying elements uniformly within the metal matrix, resulting in improved mechanical properties and enhanced durability. However, it can lead to reduced ductility and toughness, making materials more brittle and less workable compared to quenching processes. The process requires careful control of temperature and composition to avoid precipitation of unwanted phases that may weaken the material.

Choosing the Right Heat Treatment Method

Choosing the right heat treatment method involves understanding the distinct outcomes of quenching and solution hardening. Quenching rapidly cools metals, increasing hardness and strength by forming a martensitic structure, ideal for applications requiring wear resistance. Solution hardening enhances alloy strength through the solid solution of alloying elements without phase transformation, providing improved ductility and corrosion resistance for structural components.

Quenching Infographic

libterm.com

libterm.com