Pre-tensioning enhances structural strength by applying tension to steel tendons before concrete is poured, ensuring improved load distribution and reduced cracking. This technique optimizes durability and performance in various construction projects, from bridges to buildings. Explore the rest of the article to understand how pre-tensioning can benefit your next engineering project.

Table of Comparison

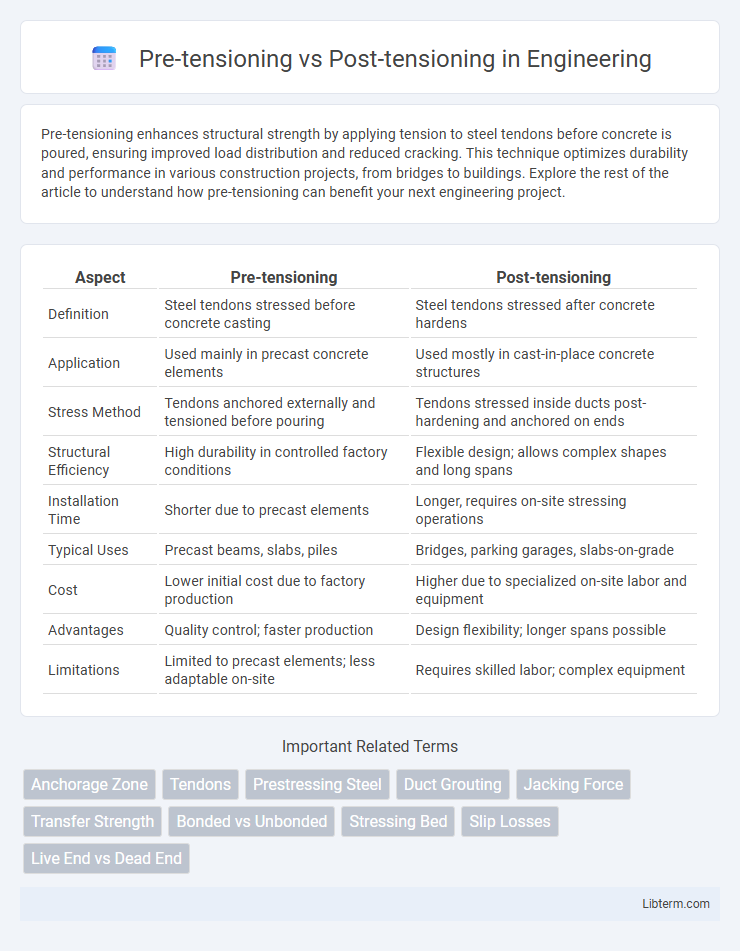

| Aspect | Pre-tensioning | Post-tensioning |

|---|---|---|

| Definition | Steel tendons stressed before concrete casting | Steel tendons stressed after concrete hardens |

| Application | Used mainly in precast concrete elements | Used mostly in cast-in-place concrete structures |

| Stress Method | Tendons anchored externally and tensioned before pouring | Tendons stressed inside ducts post-hardening and anchored on ends |

| Structural Efficiency | High durability in controlled factory conditions | Flexible design; allows complex shapes and long spans |

| Installation Time | Shorter due to precast elements | Longer, requires on-site stressing operations |

| Typical Uses | Precast beams, slabs, piles | Bridges, parking garages, slabs-on-grade |

| Cost | Lower initial cost due to factory production | Higher due to specialized on-site labor and equipment |

| Advantages | Quality control; faster production | Design flexibility; longer spans possible |

| Limitations | Limited to precast elements; less adaptable on-site | Requires skilled labor; complex equipment |

Introduction to Pre-tensioning and Post-tensioning

Pre-tensioning involves casting steel tendons in concrete before the application of external loads, enhancing tensile strength and controlling cracking. Post-tensioning occurs by tensioning steel tendons after the concrete has hardened, allowing for greater flexibility in structural design and load management. Both methods improve concrete performance but differ in installation timing and structural behavior.

Fundamentals of Prestressed Concrete

Pre-tensioning involves tensioning the steel tendons before concrete placement, creating compressive stresses that counteract tensile forces once hardened. Post-tensioning applies tension to ducts embedded within the concrete after it has cured, allowing for better adaptability to varying load conditions. Both methods optimize concrete's performance by enhancing tensile strength and reducing cracking through induced compressive stresses.

What is Pre-tensioning?

Pre-tensioning is a method in prestressed concrete where steel tendons are tensioned before the concrete is cast, ensuring the reinforcement is held under continuous stress. This technique enhances structural performance by improving load distribution and reducing cracking in beams and slabs. Mainly used in precast concrete elements, pre-tensioning offers high-quality control and faster production cycles.

What is Post-tensioning?

Post-tensioning is a concrete reinforcement technique where high-strength steel tendons are tensioned after the concrete has cured, enhancing structural capacity and reducing material usage. This method allows for thinner slabs, longer spans, and improved crack control compared to pre-tensioning. Widely used in bridges, buildings, and parking structures, post-tensioning provides increased durability and flexibility in design.

Key Differences Between Pre-tensioning and Post-tensioning

Pre-tensioning involves tensioning the steel tendons before concrete is cast, ensuring the tendons are securely anchored to external abutments, whereas post-tensioning applies tension to steel tendons after the concrete has hardened using hydraulic jacks. Pre-tensioned tendons are embedded within the concrete, providing immediate bond and load transfer, while post-tensioned tendons are housed in ducts to allow tensioning after hardening, offering greater flexibility in design and longer span capabilities. Key differences include the timing of tendon tensioning, anchorage methods, and applications: pre-tensioning suits precast elements, while post-tensioning is preferred for cast-in-place concrete and complex structures.

Advantages of Pre-tensioning

Pre-tensioning offers superior control over strand alignment and tension, resulting in enhanced structural efficiency and reduced cracking in concrete elements. This method enables faster construction cycles since strands are tensioned before concrete casting, improving overall project timelines. Pre-tensioning systems exhibit excellent bond strength between steel and concrete, ensuring long-term durability and load-bearing capacity.

Benefits of Post-tensioning

Post-tensioning offers superior structural efficiency by enabling longer spans and thinner slabs, reducing material usage and overall weight. It enhances crack control and load-bearing capacity, leading to increased durability and lower maintenance costs across bridges, buildings, and parking structures. This method also allows for rapid construction and design flexibility, optimizing project timelines and adapting to complex architectural requirements.

Applications in Construction

Pre-tensioning is commonly applied in the manufacture of precast concrete elements such as beams, slabs, and railway sleepers, where high production control and uniform stress distribution are essential. Post-tensioning is favored for cast-in-place concrete structures like bridges, parking garages, and high-rise buildings due to its adaptability in accommodating complex shapes and field adjustments. Both methods enhance structural performance by increasing load-carrying capacity, controlling cracks, and reducing material weight in construction projects.

Cost and Efficiency Comparison

Pre-tensioning involves casting tendons in place before concrete is poured, generally resulting in lower initial costs due to standardized production and reduced labor on-site. Post-tensioning requires tendons to be tensioned after concrete has cured, which can increase upfront expenses because of specialized labor and equipment but offers greater design flexibility and material efficiency for longer spans. The efficiency of post-tensioning often leads to reduced concrete volume and lighter structures, providing cost savings over the lifecycle despite higher initial investments.

Choosing the Right Method for Your Project

Pre-tensioning involves applying tension to steel tendons before casting concrete, making it ideal for precast components requiring high early strength and repetitive production. Post-tensioning, where tendons are tensioned after concrete hardens, suits cast-in-place structures offering greater flexibility in design and thickness. Selecting the right method depends on project specifics such as structural requirements, construction timeline, and cost efficiency.

Pre-tensioning Infographic

libterm.com

libterm.com