Reciprocating flow describes the back-and-forth movement of fluids within a system, commonly seen in piston engines or pumps where fluid changes direction periodically. This type of flow influences efficiency, pressure fluctuations, and mechanical wear, requiring careful analysis for optimal design and operation. Explore the rest of the article to understand how reciprocating flow impacts your machinery's performance and maintenance.

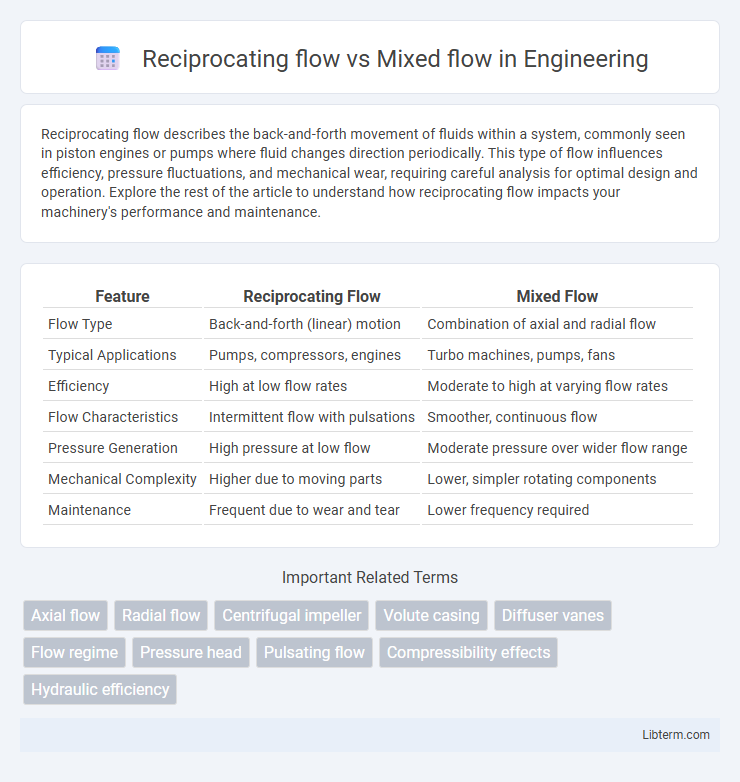

Table of Comparison

| Feature | Reciprocating Flow | Mixed Flow |

|---|---|---|

| Flow Type | Back-and-forth (linear) motion | Combination of axial and radial flow |

| Typical Applications | Pumps, compressors, engines | Turbo machines, pumps, fans |

| Efficiency | High at low flow rates | Moderate to high at varying flow rates |

| Flow Characteristics | Intermittent flow with pulsations | Smoother, continuous flow |

| Pressure Generation | High pressure at low flow | Moderate pressure over wider flow range |

| Mechanical Complexity | Higher due to moving parts | Lower, simpler rotating components |

| Maintenance | Frequent due to wear and tear | Lower frequency required |

Introduction to Reciprocating and Mixed Flow

Reciprocating flow involves the back-and-forth movement of fluid in a cylinder, common in piston pumps and compressors, providing high pressure and precise volume control. Mixed flow combines radial and axial flow components in pumps and turbines, enhancing flow rate and efficiency by directing fluid at an intermediate angle. Understanding the distinct fluid dynamics of reciprocating and mixed flow is essential for optimizing performance in hydraulic and pneumatic systems.

Fundamental Principles of Flow Mechanisms

Reciprocating flow operates on the principle of alternating movement, where fluid flows back and forth in a cyclical pattern, driven by the periodic displacement of a piston or diaphragm, creating pressure variations that enable precise volume control. Mixed flow combines axial and radial flow components, utilizing impellers designed to direct fluid both parallel and perpendicular to the shaft, enhancing efficiency by balancing flow rate and pressure. The fundamental distinction lies in reciprocating flow's pulsatile, controlled displacement mechanism versus mixed flow's continuous, high-velocity combined directional movement for optimized fluid transport.

Design Features of Reciprocating Flow Systems

Reciprocating flow systems feature pistons or diaphragms that move back and forth within cylinders to create a pulsating flow pattern, ensuring precise flow control and high-pressure capabilities. These systems incorporate valves that open and close in synchronization with the reciprocating motion, minimizing flow reversal and leakage. Their robust design supports high efficiency in applications requiring accurate dosing and pressure stability compared to mixed flow systems.

Key Characteristics of Mixed Flow Systems

Mixed flow systems combine axial and radial flow patterns, offering moderate pressure increase with higher flow rates compared to reciprocating flow systems. These systems excel in applications requiring consistent fluid movement with reduced pulsation and noise. The impeller design in mixed flow pumps optimizes efficiency across a wide range of flow conditions, making them suitable for irrigation, water treatment, and HVAC applications.

Efficiency Comparison: Reciprocating vs Mixed Flow

Reciprocating flow compressors typically achieve higher efficiency at low flow rates due to better volumetric efficiency and reduced leakage, making them ideal for high-pressure applications. Mixed flow compressors, combining axial and centrifugal principles, offer superior efficiency in handling medium to high flow rates with moderate pressure ratios, providing a balanced aerodynamic performance. Efficiency comparison depends on operational conditions, with reciprocating compressors favored for precise, high-pressure output, while mixed flow units excel in continuous, moderate-pressure environments.

Application Areas: Industry-Specific Use Cases

Reciprocating flow pumps are extensively used in industries requiring precise dosing and high-pressure delivery, such as chemical processing, oil and gas, and pharmaceuticals, where accurate flow control is critical. Mixed flow pumps excel in municipal water supply, irrigation, and flood control applications due to their ability to handle large volumes of fluid with moderate pressure efficiently. The choice between reciprocating and mixed flow pumps depends on the specific flow rate, pressure requirements, and fluid characteristics inherent to each industry's operational demands.

Maintenance and Operational Requirements

Reciprocating flow systems require frequent maintenance due to their complex valve mechanisms and high wear rates, increasing downtime and operational costs. Mixed flow systems offer smoother fluid dynamics with fewer moving parts, resulting in lower maintenance needs and enhanced reliability during continuous operation. Operationally, mixed flow pumps accommodate variable flow rates more efficiently, reducing stress on components and minimizing the risk of mechanical failure.

Performance Metrics and Output Evaluation

Reciprocating flow pumps deliver high-pressure output with precise volumetric efficiency, ideal for applications requiring steady, pulsation-free flow and reliable displacement measurement. Mixed flow pumps combine axial and radial flow effects, providing higher flow rates at moderate pressures, excelling in efficiency and energy consumption metrics for variable load conditions. Performance evaluation of reciprocating pumps centers on stroke volume consistency and pressure stability, while mixed flow pumps prioritize flow rate optimization and hydraulic efficiency across varying speed ranges.

Advantages and Limitations of Each Flow Type

Reciprocating flow systems offer precise control and high-pressure capabilities, making them ideal for applications requiring consistent flow rates and pressure stability, but they often suffer from higher maintenance due to complex moving parts. Mixed flow pumps provide a balanced combination of axial and radial flow, delivering increased flow volumes at moderate pressures with improved efficiency and smoother operation, though they may be less effective in handling very high pressures compared to reciprocating flow systems. Selecting between reciprocating and mixed flow depends on the specific requirements for pressure, flow rate, and operational durability in the given industrial application.

Choosing the Best Flow System for Your Needs

Reciprocating flow systems provide precise, pulsating fluid movement ideal for applications requiring accurate dosing or high pressure at low flow rates. Mixed flow systems combine axial and radial flow characteristics, offering a balance of high flow capacity and moderate pressure, suitable for general fluid transfer needs. Selecting the best flow system depends on factors like required flow rate, pressure conditions, and specific application demands to ensure optimal performance and energy efficiency.

Reciprocating flow Infographic

libterm.com

libterm.com