Asphaltic liners provide effective waterproofing and protection for landfills, reservoirs, and containment systems due to their impermeable and flexible properties. These liners prevent leachate seepage, safeguarding groundwater and surrounding soils from contamination. Discover how your project can benefit from asphaltic liners by exploring the full article.

Table of Comparison

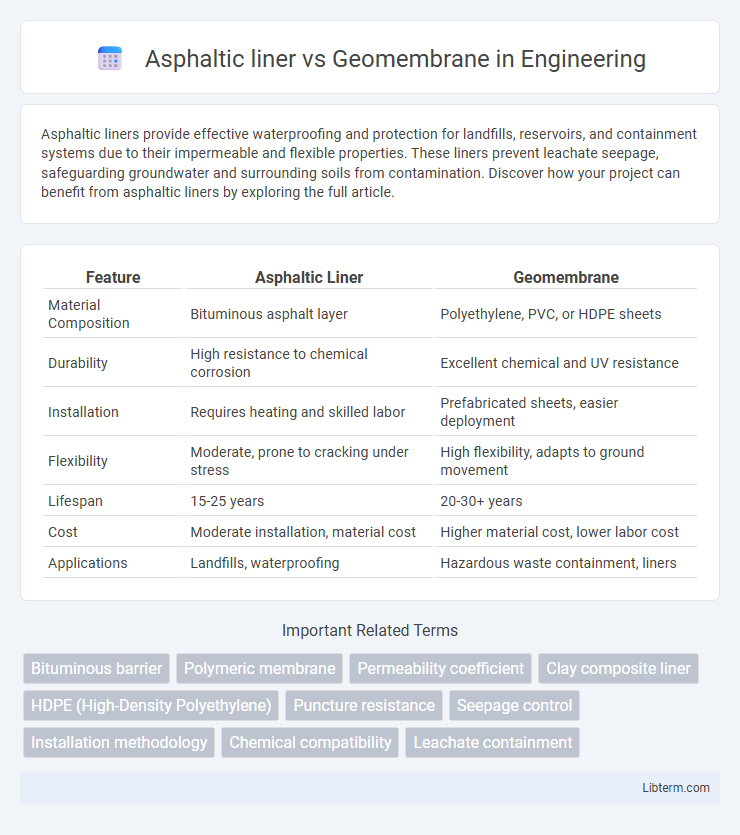

| Feature | Asphaltic Liner | Geomembrane |

|---|---|---|

| Material Composition | Bituminous asphalt layer | Polyethylene, PVC, or HDPE sheets |

| Durability | High resistance to chemical corrosion | Excellent chemical and UV resistance |

| Installation | Requires heating and skilled labor | Prefabricated sheets, easier deployment |

| Flexibility | Moderate, prone to cracking under stress | High flexibility, adapts to ground movement |

| Lifespan | 15-25 years | 20-30+ years |

| Cost | Moderate installation, material cost | Higher material cost, lower labor cost |

| Applications | Landfills, waterproofing | Hazardous waste containment, liners |

Introduction to Asphaltic Liners and Geomembranes

Asphaltic liners consist of bitumen-based materials known for their flexibility, impermeability, and durability, commonly used in environmental containment applications to prevent fluid migration. Geomembranes are synthetic polymer sheets such as HDPE, PVC, or EPDM, offering superior chemical resistance, tensile strength, and ease of installation for landfill liners, pond liners, and containment systems. Both materials serve as critical barriers in civil and environmental engineering but differ significantly in composition, performance characteristics, and application suitability.

Material Composition and Properties

Asphaltic liners are composed primarily of bitumen mixed with aggregates, offering flexibility, UV resistance, and water impermeability, making them suitable for applications requiring durability in varying temperatures. Geomembranes are synthetic membranes typically made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), characterized by high tensile strength, chemical resistance, and low permeability, ideal for containment and environmental protection. Both materials serve as effective barriers, but asphaltic liners provide enhanced elasticity while geomembranes offer superior chemical and puncture resistance.

Installation Techniques Compared

Asphaltic liners require hot application methods involving heating and troweling to form a seamless, flexible barrier, making installation labor-intensive and weather-dependent. Geomembranes, typically composed of high-density polyethylene (HDPE) or similar polymers, are installed by welding pre-fabricated sheets using thermal or extrusion welding techniques, offering faster deployment and consistent quality. The choice between the two depends on project scale, environmental conditions, and desired durability, with geomembranes favored for ease of installation and long-term performance in large containment projects.

Durability and Lifespan Analysis

Asphaltic liners exhibit excellent chemical resistance and flexibility, making them suitable for various environmental conditions, but their durability may degrade under prolonged UV exposure and temperature fluctuations. Geomembranes, particularly high-density polyethylene (HDPE) variants, offer superior resistance to punctures, UV radiation, and chemical corrosion, resulting in a longer lifespan typically ranging from 20 to 50 years depending on installation and maintenance. Lifespan analysis indicates geomembranes generally outperform asphaltic liners in long-term containment applications due to their enhanced mechanical strength and environmental resilience.

Performance in Various Environmental Conditions

Asphaltic liners exhibit excellent durability and flexibility in high-temperature and chemically aggressive environments, maintaining permeability resistance and self-healing properties under thermal stress. Geomembranes provide superior impermeability and resistance to UV radiation, ozone, and microbial degradation, ensuring consistent performance in diverse climatic conditions, including extreme cold and intense solar exposure. Both materials demonstrate robust mechanical strength, but selection depends on site-specific factors such as chemical exposure, temperature fluctuations, and expected service life.

Cost Comparison and Economic Considerations

Asphaltic liners generally offer a lower initial cost compared to geomembranes, making them a cost-effective choice for large-scale containment projects with budget constraints. Geomembranes, although more expensive upfront, provide superior durability and chemical resistance that can reduce maintenance and replacement costs over time, leading to better long-term economic value. Careful evaluation of project-specific factors such as lifespan, environmental conditions, and installation expenses is essential to determine the most cost-efficient liner option.

Environmental Impact and Sustainability

Asphaltic liners offer robust impermeability using natural bitumen, promoting durability and reduced chemical leaching, which enhances soil and groundwater protection. Geomembranes, typically made from synthetic polymers like HDPE, provide superior chemical resistance and flexibility but may pose greater environmental risks during production and disposal due to their non-biodegradable nature. Evaluating sustainability, asphaltic liners benefit from natural material sourcing and longer lifespan, while geomembranes require careful management to mitigate plastic pollution and improve recycling options.

Typical Applications and Use Cases

Asphaltic liners are primarily used for landfill covers, hydraulic barriers, and containment systems due to their excellent flexibility, UV resistance, and self-healing properties, making them ideal for waste management and environmental protection projects. Geomembranes, often fabricated from HDPE or LLDPE, serve as high-strength liners in mining, water reservoirs, and secondary containment for hazardous materials, providing superior chemical resistance and low permeability. Both materials are critical in environmental engineering, but the choice depends on specific site conditions, chemical exposure, and required durability.

Maintenance and Repair Requirements

Asphaltic liners require regular inspection for cracks and seam failures, with repairs often involving patching or reapplication of asphalt to maintain impermeability. Geomembranes demand careful monitoring for punctures or tears, and repairs typically involve welding patches or using adhesive films to restore the barrier integrity. Both materials benefit from proactive maintenance to prevent leakage and extend service life, though geomembranes generally offer simpler, faster repairs compared to the more labor-intensive upkeep of asphaltic liners.

Key Factors to Consider When Choosing Between Asphaltic Liners and Geomembranes

Asphaltic liners offer excellent flexibility and self-healing properties, making them suitable for applications with ground movement or minor punctures, while geomembranes provide superior chemical resistance and ease of installation, ideal for containment of aggressive chemicals. Key factors to consider include the expected chemical exposure, installation environment, durability requirements, and budget constraints. Thickness, resistance to UV radiation, and long-term performance are critical parameters influencing the choice between asphaltic liners and geomembranes in environmental containment projects.

Asphaltic liner Infographic

libterm.com

libterm.com