Fluid bearings use a thin layer of liquid or gas to support loads, minimizing friction and wear in high-speed machinery. Their superior durability and smooth operation make them ideal for applications requiring precision and longevity. Discover how fluid bearings can enhance the performance and reliability of your equipment throughout this article.

Table of Comparison

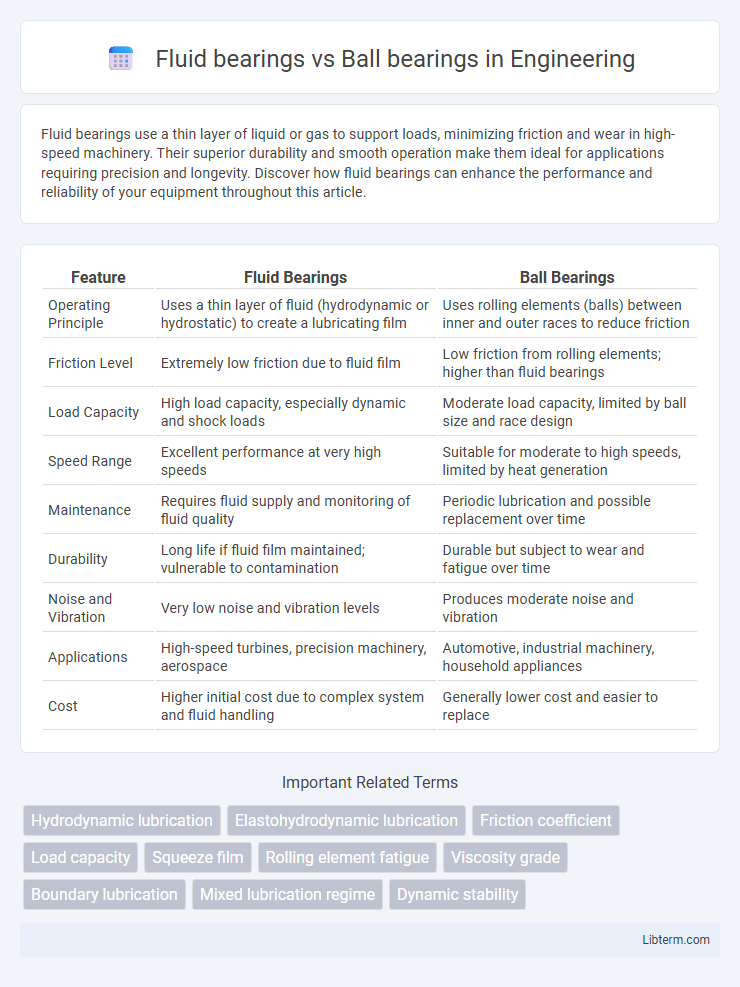

| Feature | Fluid Bearings | Ball Bearings |

|---|---|---|

| Operating Principle | Uses a thin layer of fluid (hydrodynamic or hydrostatic) to create a lubricating film | Uses rolling elements (balls) between inner and outer races to reduce friction |

| Friction Level | Extremely low friction due to fluid film | Low friction from rolling elements; higher than fluid bearings |

| Load Capacity | High load capacity, especially dynamic and shock loads | Moderate load capacity, limited by ball size and race design |

| Speed Range | Excellent performance at very high speeds | Suitable for moderate to high speeds, limited by heat generation |

| Maintenance | Requires fluid supply and monitoring of fluid quality | Periodic lubrication and possible replacement over time |

| Durability | Long life if fluid film maintained; vulnerable to contamination | Durable but subject to wear and fatigue over time |

| Noise and Vibration | Very low noise and vibration levels | Produces moderate noise and vibration |

| Applications | High-speed turbines, precision machinery, aerospace | Automotive, industrial machinery, household appliances |

| Cost | Higher initial cost due to complex system and fluid handling | Generally lower cost and easier to replace |

Introduction to Fluid Bearings and Ball Bearings

Fluid bearings utilize a thin layer of liquid or gas to support the load, significantly reducing friction and wear by creating a near-frictionless interface between moving parts. Ball bearings consist of steel or ceramic balls positioned between inner and outer races, providing rolling motion that minimizes friction and supports both radial and axial loads. Fluid bearings excel in high-speed, precision applications due to their low noise and vibration, while ball bearings are widely used for general-purpose mechanical support with robust load capacity.

Core Principles: How Fluid Bearings Work

Fluid bearings operate by maintaining a thin layer of lubricant, typically oil or gas, between the bearing surfaces, creating a hydrodynamic or hydrostatic film that supports the load and minimizes direct contact. This fluid film generates a pressure distribution that adapts to shaft speed and load, significantly reducing friction and wear compared to ball bearings' rolling elements. Fluid bearings excel in high-speed and high-precision applications due to their ability to provide near-frictionless motion and dampen vibration.

Core Principles: How Ball Bearings Work

Ball bearings operate on the principle of rolling elements placed between two concentric rings, the inner and outer races, minimizing friction by converting sliding motion into rolling motion. The spherical balls support radial and axial loads, reducing contact surface and enabling smooth rotation with low resistance. Precision in the bearing's design ensures even load distribution and extends operational lifespan by preventing metal-to-metal contact.

Key Differences Between Fluid and Ball Bearings

Fluid bearings use a thin layer of liquid or gas to create a nearly frictionless interface between moving parts, while ball bearings rely on rolling elements to reduce friction and support radial and axial loads. Fluid bearings provide superior load capacity, minimal wear, and quieter operation compared to ball bearings, which are typically simpler, more cost-effective, and easier to maintain. The key differences include load capacity, friction levels, maintenance requirements, noise generation, and suitability for high-speed or high-precision applications.

Performance Comparison: Speed, Load, and Precision

Fluid bearings excel in high-speed applications due to their low friction and superior damping capabilities, supporting speeds beyond 100,000 RPM, whereas ball bearings typically perform optimally below 50,000 RPM. Under heavy load conditions, fluid bearings distribute pressure uniformly across the surface, reducing wear and extending lifespan, while ball bearings concentrate loads on discrete points, increasing stress and maintenance needs. Precision-wise, fluid bearings provide minimal vibration and smoother motion ideal for ultra-precise machinery like semiconductor equipment, contrasting with ball bearings that may introduce slight runout and noise at high rotational speeds.

Maintenance and Longevity Factors

Fluid bearings require less frequent maintenance due to their lubrication film, which minimizes wear and friction, significantly extending their service life compared to ball bearings. Ball bearings often need regular lubrication and inspection to prevent contamination and wear, which can lead to premature failure. The longevity of fluid bearings is influenced by fluid cleanliness and operating conditions, while ball bearings' durability depends heavily on proper sealing and maintenance schedules.

Noise and Vibration Characteristics

Fluid bearings exhibit significantly lower noise and vibration levels compared to ball bearings due to the continuous lubricant film that minimizes metal-to-metal contact. This hydrodynamic lubrication reduces friction and operational sound, making fluid bearings ideal for precision applications in medical imaging and semiconductor manufacturing. Ball bearings generate higher noise and vibration as rolling elements create impact forces, which can lead to wear and decreased performance in sensitive environments.

Applications: Where Each Bearing Excels

Fluid bearings excel in high-speed, precision applications such as turbines, computer hard drives, and semiconductor manufacturing equipment due to their low friction and vibration damping properties. Ball bearings are preferred in automotive, aerospace, and industrial machinery where durability, load capacity, and cost-effectiveness are critical. Each bearing's design caters to specific operational demands, with fluid bearings enhancing smooth, quiet rotation under high speeds, and ball bearings providing reliable performance under diverse load conditions.

Cost Analysis: Initial Investment and Lifespan

Fluid bearings generally require a higher initial investment compared to ball bearings due to their complex design and precision manufacturing. However, the extended lifespan and reduced maintenance costs of fluid bearings often result in lower total ownership costs over time. Ball bearings, while cheaper upfront, may incur higher long-term expenses due to increased wear and more frequent replacements.

Choosing the Right Bearing for Your Application

Fluid bearings offer superior precision and reduced friction ideal for high-speed applications requiring minimal noise and wear, while ball bearings provide robust load capacity and versatility suited for varied industrial uses. Selecting the right bearing depends on factors such as load type, speed, temperature, and maintenance requirements, with fluid bearings excelling in environments demanding clean operation and longevity, and ball bearings benefiting cost-effective, heavy-load scenarios. Evaluating operational conditions and performance goals ensures optimal bearing choice for enhanced machinery efficiency and lifespan.

Fluid bearings Infographic

libterm.com

libterm.com