A tubular shaft offers superior strength-to-weight ratio compared to solid shafts, making it ideal for applications requiring high torque and rigidity with minimal weight. Its hollow construction enhances resistance to bending and torsion, improving performance in automotive, aerospace, and industrial machinery components. Explore the rest of the article to discover how a tubular shaft can optimize your mechanical designs.

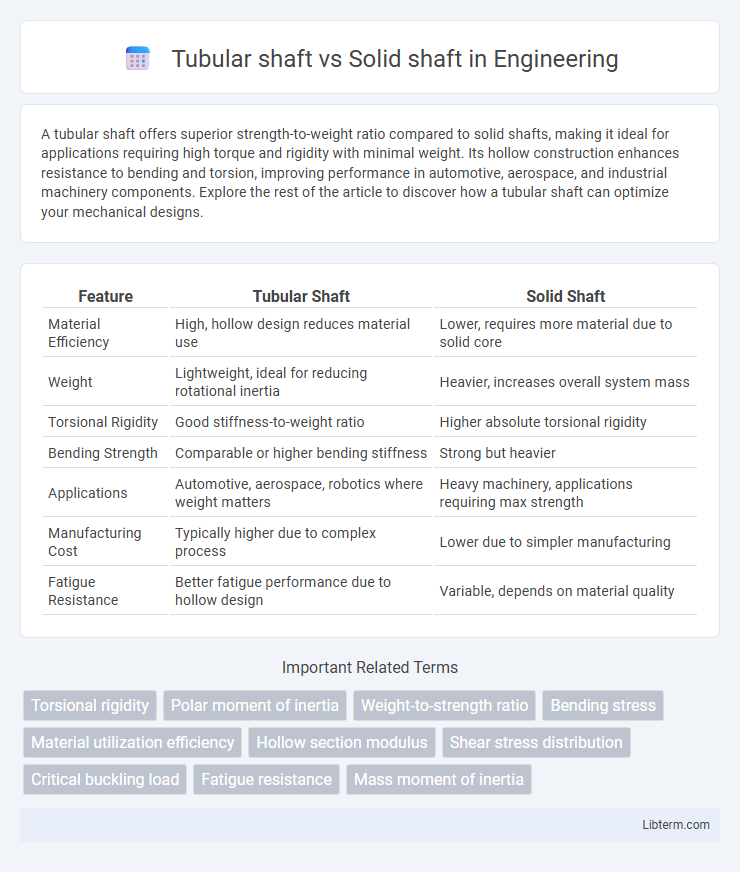

Table of Comparison

| Feature | Tubular Shaft | Solid Shaft |

|---|---|---|

| Material Efficiency | High, hollow design reduces material use | Lower, requires more material due to solid core |

| Weight | Lightweight, ideal for reducing rotational inertia | Heavier, increases overall system mass |

| Torsional Rigidity | Good stiffness-to-weight ratio | Higher absolute torsional rigidity |

| Bending Strength | Comparable or higher bending stiffness | Strong but heavier |

| Applications | Automotive, aerospace, robotics where weight matters | Heavy machinery, applications requiring max strength |

| Manufacturing Cost | Typically higher due to complex process | Lower due to simpler manufacturing |

| Fatigue Resistance | Better fatigue performance due to hollow design | Variable, depends on material quality |

Introduction to Tubular and Solid Shafts

Tubular shafts are hollow cylindrical structures designed to reduce weight while maintaining high strength and stiffness, commonly used in automotive and aerospace applications for torque transmission. Solid shafts, made from a single piece of metal, provide higher torsional rigidity and are preferred in heavy-duty machinery where strength is critical. The choice between tubular and solid shafts depends on factors like weight constraints, strength requirements, and manufacturing costs.

Key Differences Between Tubular and Solid Shafts

Tubular shafts offer higher strength-to-weight ratios compared to solid shafts, making them ideal for applications requiring lightweight yet durable components. Solid shafts provide greater torsional rigidity and are generally easier to manufacture, which suits heavy-duty machinery needing maximum strength. The choice between tubular and solid shafts hinges on factors like weight constraints, load capacity, and manufacturing complexity.

Material Composition and Manufacturing

Tubular shafts are typically made from high-strength steel alloys such as chromoly or stainless steel, offering a lightweight structure with high torsional rigidity due to their hollow design. Solid shafts are often manufactured from forged steel or carbon steel, providing superior strength and durability through a dense, uniform material composition. Manufacturing processes for tubular shafts involve precision welding or seamless extrusion to maintain structural integrity, whereas solid shafts are commonly produced via forging, machining, and heat treatment to enhance mechanical properties.

Strength and Load-Bearing Capacity

Tubular shafts exhibit higher strength-to-weight ratios compared to solid shafts, enabling efficient resistance to torsional and bending stresses while minimizing material usage. Solid shafts generally provide greater load-bearing capacity due to their uniform cross-section, making them suitable for applications with extremely high static loads. The choice between tubular and solid shafts depends on specific strength requirements and load conditions, with tubular shafts preferred for lightweight and high-strength scenarios.

Weight Comparison and Efficiency

Tubular shafts offer significant weight reduction compared to solid shafts due to their hollow structure, enhancing overall system efficiency by decreasing rotational inertia and energy consumption. The reduced weight of tubular shafts improves dynamic performance and lowers material costs without compromising strength or durability, making them ideal for applications requiring lightweight yet robust components. In contrast, solid shafts, while often easier to manufacture, tend to be heavier and less efficient in energy transfer, impacting fuel efficiency and operational costs in mechanical systems.

Torsional Resistance and Performance

Tubular shafts exhibit higher torsional resistance compared to solid shafts of the same weight due to their larger polar moment of inertia, enhancing performance under twisting loads. The hollow design reduces weight while maintaining stiffness, improving efficiency in applications requiring torque transmission. Solid shafts provide uniform material distribution but typically result in higher weight and lower strength-to-weight ratios in torsional performance.

Applications in Engineering and Industry

Tubular shafts are widely used in automotive and aerospace engineering due to their high strength-to-weight ratio and resistance to torsional stress, making them ideal for drive shafts and aircraft components. Solid shafts are favored in heavy machinery and power transmission applications for their superior rigidity and ability to withstand high bending loads and shock forces. The choice between tubular and solid shafts depends on the specific application requirements, such as weight constraints, load conditions, and mechanical performance demands in industry.

Cost Analysis and Economic Considerations

Tubular shafts generally offer a better strength-to-weight ratio than solid shafts, leading to lower material costs despite potentially higher manufacturing complexity. The reduced weight of tubular shafts can also result in decreased energy consumption and maintenance expenses over time. Economic considerations favor tubular shafts in applications where cost savings on materials and operational efficiency outweigh the initial production investment.

Durability and Maintenance Requirements

Tubular shafts offer enhanced durability due to their high strength-to-weight ratio and resistance to torsional stress, making them less prone to bending and fatigue compared to solid shafts. Maintenance requirements for tubular shafts are generally lower as their hollow design reduces material wear and facilitates easier inspection for internal corrosion. Solid shafts, while rugged and simple in design, often require more frequent maintenance to address surface wear and potential deformation under heavy loads.

Choosing the Right Shaft for Your Application

Tubular shafts offer a high strength-to-weight ratio, making them ideal for applications requiring reduced mass and improved torsional rigidity, such as automotive drive shafts and aerospace components. Solid shafts provide greater resistance to bending and fatigue, suited for heavy-duty machinery and industrial equipment where durability is critical. Selecting the right shaft depends on load conditions, weight constraints, and specific mechanical properties required for optimal performance in your application.

Tubular shaft Infographic

libterm.com

libterm.com