Flame hardening is a heat treatment process that enhances the surface hardness of steel by rapidly heating it with an oxy-fuel flame followed by immediate quenching. This technique improves wear resistance and extends the lifespan of components such as gears, shafts, and machine parts. Explore the rest of the article to understand how flame hardening can improve your manufacturing processes.

Table of Comparison

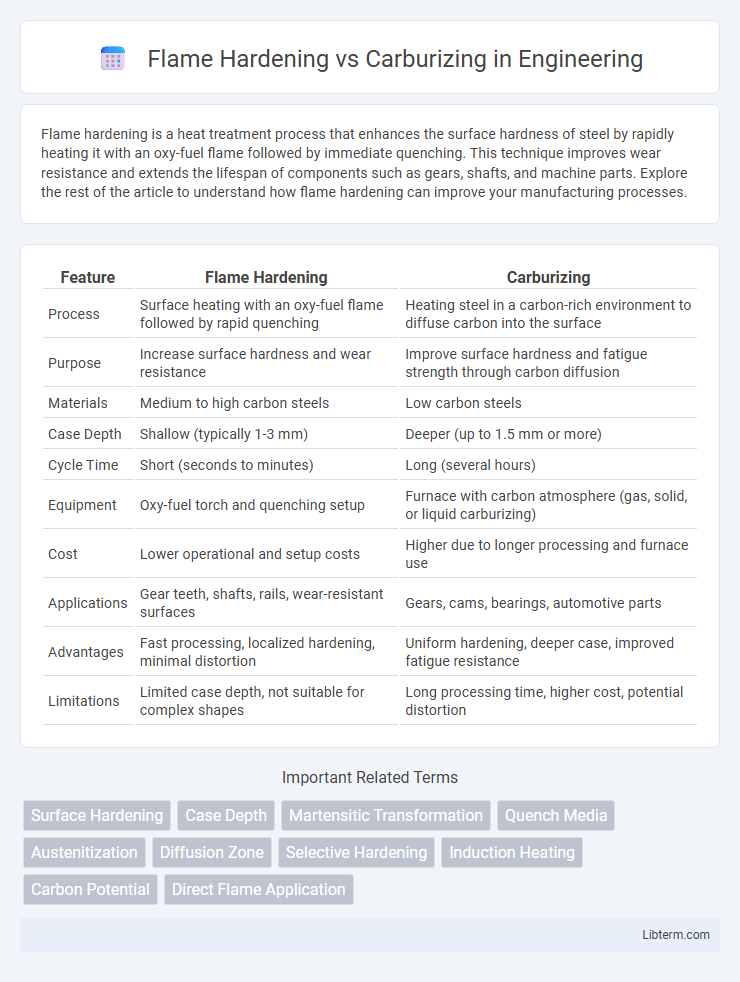

| Feature | Flame Hardening | Carburizing |

|---|---|---|

| Process | Surface heating with an oxy-fuel flame followed by rapid quenching | Heating steel in a carbon-rich environment to diffuse carbon into the surface |

| Purpose | Increase surface hardness and wear resistance | Improve surface hardness and fatigue strength through carbon diffusion |

| Materials | Medium to high carbon steels | Low carbon steels |

| Case Depth | Shallow (typically 1-3 mm) | Deeper (up to 1.5 mm or more) |

| Cycle Time | Short (seconds to minutes) | Long (several hours) |

| Equipment | Oxy-fuel torch and quenching setup | Furnace with carbon atmosphere (gas, solid, or liquid carburizing) |

| Cost | Lower operational and setup costs | Higher due to longer processing and furnace use |

| Applications | Gear teeth, shafts, rails, wear-resistant surfaces | Gears, cams, bearings, automotive parts |

| Advantages | Fast processing, localized hardening, minimal distortion | Uniform hardening, deeper case, improved fatigue resistance |

| Limitations | Limited case depth, not suitable for complex shapes | Long processing time, higher cost, potential distortion |

Introduction to Surface Hardening Techniques

Surface hardening techniques like flame hardening and carburizing enhance the wear resistance and fatigue life of steel components by modifying only the outer layer while maintaining a ductile core. Flame hardening uses an oxy-fuel flame to rapidly heat the steel surface followed by immediate quenching, creating a hard martensitic layer ideal for large or irregular parts. Carburizing involves diffusing carbon into the metal surface at elevated temperatures in a carbon-rich atmosphere, producing a deeper hardened case suitable for intricate shapes and high-load applications.

Overview of Flame Hardening

Flame hardening is a surface hardening process that uses an oxy-fuel flame to rapidly heat the metal's surface, followed by immediate quenching to increase hardness and wear resistance. This method is commonly applied to steel components like shafts, gears, and rails to enhance fatigue strength without affecting the core's toughness. Flame hardening offers advantages such as localized hardening, minimal distortion, and cost efficiency compared to carburizing, which involves diffusing carbon into the metal surface at high temperatures over extended periods.

Overview of Carburizing

Carburizing is a heat treatment process that introduces carbon into the surface layer of low-carbon steel, enhancing hardness and wear resistance while maintaining a tough core. This technique improves fatigue strength and extends the component's service life, making it ideal for gears, shafts, and other high-stress applications. Carburizing typically involves heating the steel in a carbon-rich environment, followed by quenching to lock the carbon into the surface.

Key Differences between Flame Hardening and Carburizing

Flame hardening heats the surface of steel using an oxy-fuel flame followed by rapid quenching to increase hardness, targeting only the outer layer for wear resistance, while carburizing involves diffusing carbon into the steel surface at high temperatures over an extended period to form a hard, wear-resistant carburized case. Flame hardening is faster and suited for specific localized areas, whereas carburizing provides deeper and more uniform case hardening but requires longer processing and furnace equipment. The key difference lies in the method of hardening--flame hardening uses direct heating and quenching, while carburizing employs carbon diffusion and subsequent controlled cooling.

Materials Suitable for Flame Hardening vs Carburizing

Flame hardening is most effective on steels with a carbon content above 0.3%, such as medium and high-carbon steels, and is commonly applied to tool steel and structural steel components requiring wear-resistant surfaces. Carburizing is suitable for low-carbon steels, typically below 0.3% carbon, where the process enriches the surface with additional carbon to increase hardness, ideal for parts like gears and camshafts that demand a tough core and a hard exterior. Both methods enhance surface hardness but differ in material compatibility due to their reliance on initial carbon content and desired depth of hardened layer.

Process Steps: Flame Hardening Explained

Flame hardening is a surface hardening process involving rapid heating of the metal surface using an oxy-fuel gas flame, followed by immediate quenching with water or oil to create a hard, wear-resistant layer. The process steps include preheating the metal to austenitizing temperature, uniformly applying the flame to the desired area, and performing quick cooling to transform the microstructure into martensite. This technique targets localized hardening, enhancing surface hardness without affecting the core properties of components like shafts, gears, and rails.

Process Steps: Carburizing Explained

Carburizing involves heating steel in a carbon-rich environment, allowing carbon atoms to diffuse into the metal surface, enhancing hardness and wear resistance. The process steps include heating the component to a temperature between 900degC and 950degC, maintaining it in a carbon-bearing atmosphere, and then quenching to lock in the hardened outer layer. This controlled diffusion process results in a tough, wear-resistant case while maintaining a ductile core.

Comparative Advantages and Disadvantages

Flame hardening offers rapid surface hardening with minimal distortion, making it ideal for large, complex shapes, while carburizing provides deeper case hardening suitable for high wear resistance and fatigue strength. Flame hardening generally requires less processing time and is cost-effective for shorter runs, whereas carburizing involves longer cycles and controlled atmospheres, increasing complexity and cost. However, carburizing achieves more uniform hardness depth and better dimensional stability, making it preferable for components subjected to high stress over prolonged use.

Typical Applications in Industry

Flame hardening is typically applied in the automotive and heavy machinery industries for components like shafts, gears, and rails where surface wear resistance and toughness are critical. Carburizing finds extensive use in manufacturing high-strength parts such as carburized gears, camshafts, and bearings, providing a hard, wear-resistant surface with a ductile core. Both processes enhance durability but are selected based on component geometry and specific performance requirements in sectors like aerospace, automotive, and industrial equipment.

Choosing the Right Hardening Technique

Choosing the right hardening technique depends on the desired surface properties and application requirements; flame hardening offers rapid surface hardening with precise control, ideal for large components requiring wear resistance without core hardness alteration. Carburizing provides deep carbon diffusion, creating a hard, wear-resistant outer layer with a tough, ductile core, making it suitable for complex parts subject to heavy stress. Evaluating factors like component size, complexity, load conditions, and cost-efficiency guides the optimal selection between flame hardening and carburizing.

Flame Hardening Infographic

libterm.com

libterm.com