Stress ratio is a critical parameter in fatigue analysis that represents the ratio of minimum to maximum stress experienced during cyclic loading. Understanding this ratio helps predict material behavior under repeated stress and enhances the durability assessment of components. Explore the rest of the article to learn how stress ratio impacts fatigue life and design considerations.

Table of Comparison

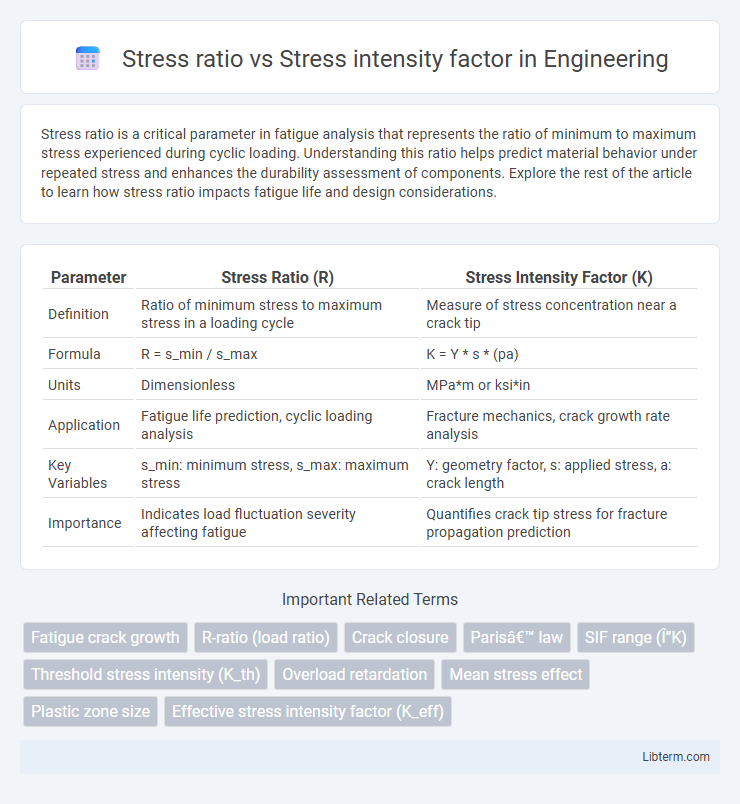

| Parameter | Stress Ratio (R) | Stress Intensity Factor (K) |

|---|---|---|

| Definition | Ratio of minimum stress to maximum stress in a loading cycle | Measure of stress concentration near a crack tip |

| Formula | R = s_min / s_max | K = Y * s * (pa) |

| Units | Dimensionless | MPa*m or ksi*in |

| Application | Fatigue life prediction, cyclic loading analysis | Fracture mechanics, crack growth rate analysis |

| Key Variables | s_min: minimum stress, s_max: maximum stress | Y: geometry factor, s: applied stress, a: crack length |

| Importance | Indicates load fluctuation severity affecting fatigue | Quantifies crack tip stress for fracture propagation prediction |

Understanding Stress Ratio: Definition and Importance

Stress ratio, defined as the ratio of minimum to maximum cyclic stress in fatigue loading, is crucial for predicting material behavior under repeated stress. It influences crack growth rates by affecting the stress intensity factor range, which quantifies the stress state near a crack tip. Understanding stress ratio enables more accurate fatigue life assessments and enhances the reliability of structural components.

The Fundamentals of Stress Intensity Factor (SIF)

Stress intensity factor (SIF) quantifies the stress state near the tip of a crack, serving as a critical parameter in fracture mechanics to predict crack propagation under various loading conditions. Unlike stress ratio, which describes the cyclical loading magnitude during fatigue, SIF integrates material properties, crack size, and applied load to assess the potential for crack growth and failure. Understanding the fundamentals of SIF enhances accurate evaluation of structural integrity and lifespan in engineering components subject to fracture.

Relationship Between Stress Ratio and SIF

The relationship between stress ratio (R) and stress intensity factor (SIF) is crucial in fracture mechanics, as the stress ratio influences the magnitude and variation of the SIF during cyclic loading. Higher stress ratios typically result in increased minimum SIF values, reducing the effective SIF range (DK) and affecting crack growth rates. Understanding this interplay aids in accurately predicting fatigue life and crack propagation in materials subjected to fluctuating stresses.

Effects of Stress Ratio on Crack Initiation

Stress ratio (R), defined as the ratio of minimum to maximum stress in a loading cycle, significantly influences crack initiation by altering the mean stress level and cyclic stress amplitude. Higher stress ratios reduce compressive stress during unloading, promoting greater crack tip opening and accelerating crack initiation compared to lower ratios with higher compressive stresses. The stress intensity factor range (DK) correlates with the applied load range, but the stress ratio modifies the effective driving force for crack nucleation and early growth, making R a critical parameter in fatigue life prediction models.

Influence of Stress Intensity Factor on Fracture Mechanics

The stress intensity factor (K) quantitatively describes the stress state near the tip of a crack and directly influences crack propagation and fracture toughness in materials. Unlike the stress ratio (R), which is a cyclic load parameter, the stress intensity factor focuses on the severity of stress concentration, determining whether a crack will grow under a given loading condition. Accurate evaluation of K is critical in fracture mechanics for predicting failure and ensuring structural integrity in components subjected to fluctuating or static stresses.

Analytical Models Linking Stress Ratio and SIF

Analytical models linking stress ratio (R) and stress intensity factor (SIF) provide critical insights into fatigue crack growth behavior under cyclic loading conditions. These models incorporate factors such as crack opening stress and load interaction effects to relate the effective stress intensity range (DK_eff) to the applied stress ratio, enabling more accurate predictions of fatigue life in structural materials. Understanding this relationship is essential for optimizing fracture mechanics approaches in the assessment of damage tolerance and crack propagation rates in metals and composites.

Stress Ratio Variations in Fatigue Testing

Stress ratio (R) significantly influences fatigue life by affecting crack growth rates under cyclic loading. Variations in stress ratio alter the stress intensity factor range (DK), with higher R values increasing minimum load levels and reducing the effective stress intensity factor range, thereby impacting fatigue crack propagation behavior. Accurate fatigue testing requires controlling and reporting stress ratio to predict component durability and optimize material performance under variable cyclic stresses.

Impact of SIF on Material Fatigue Life

The stress intensity factor (SIF) quantifies the stress state near the tip of a crack and critically influences fatigue crack growth rates in materials, thereby directly affecting fatigue life. Unlike the stress ratio, which is the ratio of minimum to maximum cyclic stress, SIF incorporates crack size and geometry, providing a more precise prediction of crack propagation behavior under cyclic loading. Higher SIF values accelerate crack growth, drastically reducing the material's fatigue life by increasing the likelihood of fracture at lower cyclic stresses.

Practical Applications: Engineering Design Considerations

Stress ratio (R), defined as the ratio of minimum to maximum stress during a load cycle, directly influences fatigue life predictions in materials, as higher stress ratios often correspond to reduced crack growth thresholds. The stress intensity factor (K) quantifies the magnitude of the stress field near a crack tip and is crucial for fracture mechanics assessments, determining critical crack sizes to prevent catastrophic failure. Engineering design incorporates both parameters by optimizing load cycles (stress ratio) and material toughness (stress intensity factor) to enhance durability and safety of structures under cyclic loading conditions.

Future Trends in Stress Ratio and SIF Research

Emerging research in stress ratio and stress intensity factor (SIF) is focusing on advanced predictive models integrating machine learning algorithms for fatigue life assessment. Future trends emphasize real-time monitoring techniques combined with high-resolution sensor data to improve accuracy in crack growth prediction under variable stress ratios. Innovations in materials science, including composite and nano-engineered materials, are driving new methodologies that link stress ratio effects directly with SIF behavior to optimize structural health monitoring systems.

Stress ratio Infographic

libterm.com

libterm.com