Just-In-Time (JIT) is a production strategy focused on reducing inventory costs by receiving goods only as they are needed in the manufacturing process, thereby minimizing waste and increasing efficiency. This method enhances your supply chain's responsiveness and can significantly improve cash flow by lowering storage expenses. Explore the rest of this article to understand how implementing JIT can streamline operations and boost profitability.

Table of Comparison

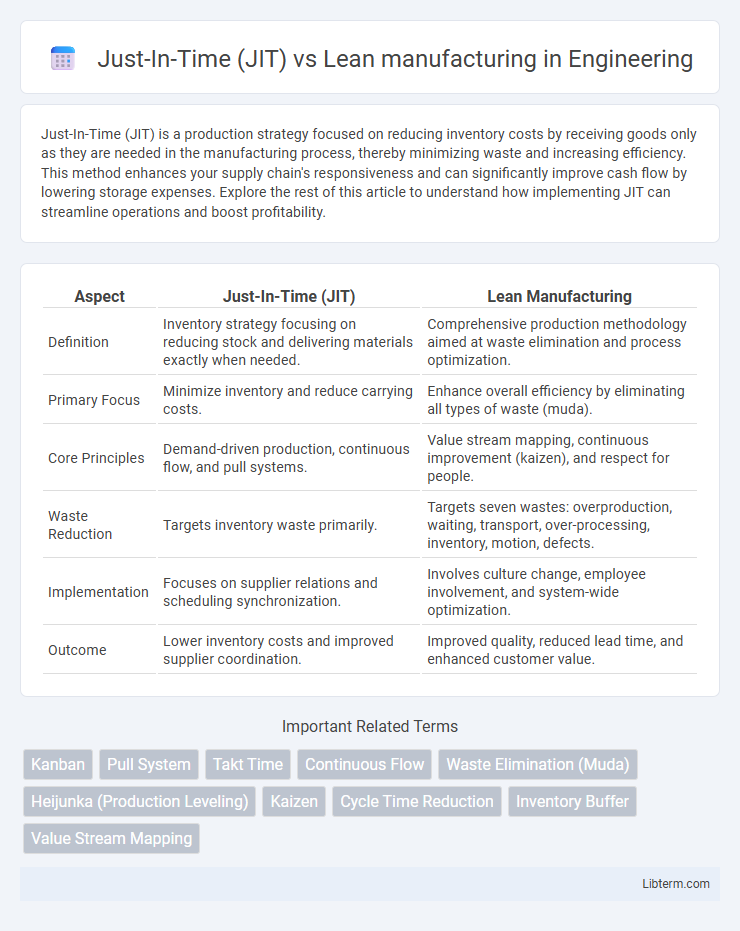

| Aspect | Just-In-Time (JIT) | Lean Manufacturing |

|---|---|---|

| Definition | Inventory strategy focusing on reducing stock and delivering materials exactly when needed. | Comprehensive production methodology aimed at waste elimination and process optimization. |

| Primary Focus | Minimize inventory and reduce carrying costs. | Enhance overall efficiency by eliminating all types of waste (muda). |

| Core Principles | Demand-driven production, continuous flow, and pull systems. | Value stream mapping, continuous improvement (kaizen), and respect for people. |

| Waste Reduction | Targets inventory waste primarily. | Targets seven wastes: overproduction, waiting, transport, over-processing, inventory, motion, defects. |

| Implementation | Focuses on supplier relations and scheduling synchronization. | Involves culture change, employee involvement, and system-wide optimization. |

| Outcome | Lower inventory costs and improved supplier coordination. | Improved quality, reduced lead time, and enhanced customer value. |

Introduction to Just-In-Time (JIT) and Lean Manufacturing

Just-In-Time (JIT) is a manufacturing strategy that reduces inventory costs by receiving goods only as they are needed in the production process, emphasizing waste reduction and continuous improvement. Lean manufacturing focuses on maximizing value for the customer by eliminating non-value-added activities and streamlining processes across the entire production system. Both methods aim to enhance efficiency, improve product quality, and minimize waste, but JIT specifically targets inventory management while Lean addresses broader operational improvements.

Core Principles of JIT Manufacturing

Just-In-Time (JIT) manufacturing centers on eliminating waste through precise inventory management, producing only what is needed, when it's needed, and in the exact quantity required. Core principles include continuous flow of production, demand-driven pull systems, and strong supplier relationships to ensure timely delivery of materials. JIT emphasizes reducing lead times, minimizing inventory levels, and improving product quality by addressing issues immediately on the production line.

Key Concepts Behind Lean Manufacturing

Lean manufacturing centers on maximizing value by eliminating waste, emphasizing continuous improvement (Kaizen), and fostering a culture of respect for people. Core principles include value stream mapping, just-in-time production, and jidoka (automation with a human touch) to streamline processes and enhance quality. Lean also prioritizes pull systems over push production to align inventory levels with actual demand, reducing excess stock and lead times.

Similarities Between JIT and Lean Approaches

Just-In-Time (JIT) and Lean manufacturing both prioritize waste reduction and efficiency improvement by streamlining production processes and minimizing inventory levels. Both methodologies emphasize continuous improvement, employee involvement, and the elimination of non-value-added activities to enhance product quality and reduce lead times. By focusing on demand-driven production and optimizing workflow, JIT and Lean enable organizations to respond swiftly to market changes while lowering operational costs.

Differences: JIT vs Lean Manufacturing

Just-In-Time (JIT) manufacturing emphasizes eliminating inventory waste by producing products only as needed, aiming for zero inventory and real-time demand fulfillment. Lean manufacturing is a broader philosophy focused on overall waste reduction in processes, including defects, overproduction, and inefficient workflows, to improve value for the customer. While JIT targets inventory control and flow synchronization, Lean encompasses a wider range of continuous improvement practices and cultural change within the organization.

Benefits of Implementing JIT

Implementing Just-In-Time (JIT) manufacturing significantly reduces inventory costs by minimizing stock levels and promoting continuous flow, leading to improved cash flow and reduced waste. JIT enhances production efficiency through precise demand forecasting and timely material delivery, which decreases lead times and increases responsiveness to market changes. Emphasizing quality at every production stage reduces defects and rework, contributing to higher customer satisfaction and overall operational excellence.

Advantages of Lean Manufacturing Systems

Lean manufacturing systems reduce waste by eliminating non-value-added activities, leading to increased operational efficiency and lower production costs. They emphasize continuous improvement (Kaizen) and empower employees through teamwork and problem-solving, which enhances product quality and customer satisfaction. Lean methods also improve flexibility and responsiveness to market changes by streamlining processes and optimizing resource utilization.

Challenges and Limitations of JIT and Lean

Just-In-Time (JIT) manufacturing faces challenges such as supply chain disruptions, requiring precise inventory timing that can halt production if delays occur. Lean manufacturing's limitations include potential employee burnout and the risk of over-eliminating resources, which may reduce flexibility and innovation. Both systems demand rigorous implementation and continuous improvement to avoid inefficiencies and maintain operational resilience.

Choosing Between JIT and Lean for Your Business

Choosing between Just-In-Time (JIT) and Lean manufacturing depends on your business's production complexity, inventory capacity, and demand variability. JIT focuses on minimizing inventory by receiving goods only as needed, reducing waste and storage costs for companies with stable demand and reliable suppliers. Lean manufacturing offers a broader approach by optimizing overall processes, enhancing quality, and eliminating all forms of waste, making it suitable for businesses seeking comprehensive process improvement beyond inventory reduction.

Future Trends in Manufacturing: JIT and Lean Integration

Future trends in manufacturing emphasize the seamless integration of Just-In-Time (JIT) and Lean manufacturing to optimize efficiency and reduce waste. Advanced technologies such as AI-driven analytics, IoT-enabled real-time monitoring, and automation facilitate synchronized inventory management and continuous process improvements. This convergence supports predictive maintenance, enhanced supply chain resilience, and sustainable production practices aligned with Industry 4.0 standards.

Just-In-Time (JIT) Infographic

libterm.com

libterm.com