Strength is the ability to exert force and withstand pressure, essential for physical performance and injury prevention. Building your strength enhances endurance, supports daily activities, and improves overall health. Discover effective strategies to boost your strength throughout this article.

Table of Comparison

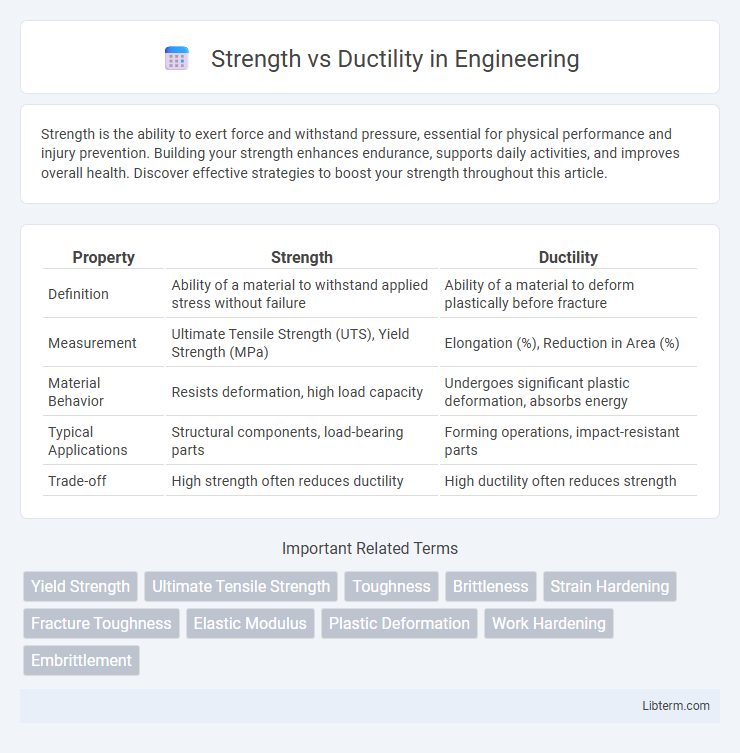

| Property | Strength | Ductility |

|---|---|---|

| Definition | Ability of a material to withstand applied stress without failure | Ability of a material to deform plastically before fracture |

| Measurement | Ultimate Tensile Strength (UTS), Yield Strength (MPa) | Elongation (%), Reduction in Area (%) |

| Material Behavior | Resists deformation, high load capacity | Undergoes significant plastic deformation, absorbs energy |

| Typical Applications | Structural components, load-bearing parts | Forming operations, impact-resistant parts |

| Trade-off | High strength often reduces ductility | High ductility often reduces strength |

Understanding Strength and Ductility

Strength refers to a material's ability to withstand an applied load without failure, measured by properties such as tensile strength, yield strength, and compressive strength. Ductility indicates the extent to which a material can deform plastically before fracturing, often quantified by elongation or reduction in area during tensile testing. Understanding the balance between strength and ductility is crucial for selecting materials that ensure structural integrity while allowing enough deformation to absorb energy and prevent sudden failure.

Key Differences Between Strength and Ductility

Strength measures a material's ability to withstand an applied load without failure, typically quantified by tensile strength or yield strength. Ductility refers to a material's capacity to undergo significant plastic deformation before rupture, often expressed as the percent elongation or reduction in area. Key differences lie in their functional roles: strength emphasizes resistance to permanent shape change, while ductility indicates flexibility and energy absorption during deformation.

Importance in Material Selection

Strength and ductility are critical factors in material selection, balancing load-bearing capacity with deformation capability to prevent failure. High strength materials resist applied forces and maintain structural integrity, while ductile materials absorb energy through plastic deformation, enhancing toughness and safety. Optimizing the combination of strength and ductility ensures durability and performance in applications ranging from aerospace components to civil engineering structures.

Factors Affecting Strength and Ductility

Material strength depends on factors such as grain size, alloying elements, and heat treatment, which influence dislocation movement and overall structural integrity. Ductility is primarily affected by temperature, strain rate, and the presence of impurities or second-phase particles that can hinder plastic deformation. Optimizing these factors balances strength and ductility, crucial for applications requiring both high load-bearing capacity and flexibility.

Types of Strength in Engineering Materials

Engineering materials exhibit different types of strength, including tensile strength, compressive strength, shear strength, and fatigue strength, each critical for specific load-bearing applications. Tensile strength measures resistance to being pulled apart, while compressive strength reflects the ability to withstand pushing forces, and shear strength evaluates the material's response to sliding forces. Understanding these strength types is essential for optimizing ductility, which represents a material's capacity to deform plastically before failure, ensuring safety and durability in engineering designs.

Balancing Strength and Ductility in Design

Balancing strength and ductility in material design is crucial for optimizing performance and durability, especially in structural applications where both load-bearing capacity and deformation tolerance are vital. High-strength materials often sacrifice ductility, leading to brittle failure, while highly ductile materials may lack sufficient strength for demanding loads. Advanced alloying techniques and microstructural engineering enable designers to tailor materials that achieve a synergistic balance, enhancing safety and longevity in construction and manufacturing industries.

Testing Methods for Strength and Ductility

Tensile testing is the primary method for evaluating both strength and ductility, measuring a material's ultimate tensile strength and elongation at fracture. Hardness tests, such as Rockwell or Brinell, assess strength by determining resistance to localized plastic deformation but provide limited insight into ductility. Charpy impact and bend tests specifically focus on ductility by measuring energy absorption and deformation before failure under sudden or bending loads.

Applications Favoring High Strength

High-strength materials are essential in aerospace engineering, automotive manufacturing, and construction where load-bearing capacity and resistance to deformation are critical. Structural steel, titanium alloys, and carbon fiber composites provide superior strength-to-weight ratios, enabling the design of lighter, safer, and more durable components. Applications favoring high strength prioritize materials that withstand extreme stress, impact, and fatigue while minimizing material usage for cost efficiency and performance optimization.

Applications Requiring High Ductility

Materials with high ductility are crucial for applications demanding extensive deformation without fracture, such as automotive crash components and aerospace structures. Ductile metals like aluminum alloys and copper allow for energy absorption and shape flexibility, enhancing safety and performance under dynamic loading. This property also facilitates manufacturing processes like forming, bending, and extrusion, making ductility essential in metalworking industries.

Improving Strength-Ductility Trade-Offs

Improving strength-ductility trade-offs involves developing advanced materials that balance high tensile strength with adequate plastic deformation capacity, crucial for structural applications. Techniques such as alloying, grain refinement, and thermo-mechanical processing enhance microstructural features, optimizing dislocation movement and phase transformations for better strength and ductility synergy. Innovations in nanostructured metals and multi-phase composites demonstrate significant progress in mitigating the inverse relationship between strength and ductility, leading to materials with superior mechanical performance.

Strength Infographic

libterm.com

libterm.com