Drawing enhances creativity and improves fine motor skills, making it an essential artistic practice. It allows You to communicate ideas visually and develop unique personal styles through various techniques and mediums. Explore the rest of this article to discover tips and methods that can elevate Your drawing skills.

Table of Comparison

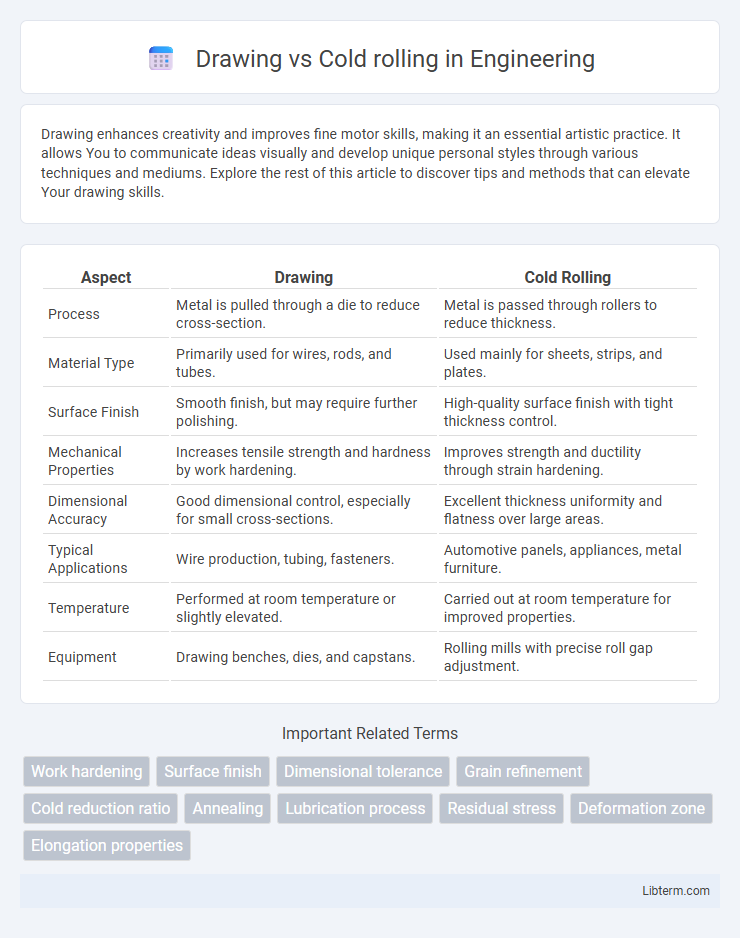

| Aspect | Drawing | Cold Rolling |

|---|---|---|

| Process | Metal is pulled through a die to reduce cross-section. | Metal is passed through rollers to reduce thickness. |

| Material Type | Primarily used for wires, rods, and tubes. | Used mainly for sheets, strips, and plates. |

| Surface Finish | Smooth finish, but may require further polishing. | High-quality surface finish with tight thickness control. |

| Mechanical Properties | Increases tensile strength and hardness by work hardening. | Improves strength and ductility through strain hardening. |

| Dimensional Accuracy | Good dimensional control, especially for small cross-sections. | Excellent thickness uniformity and flatness over large areas. |

| Typical Applications | Wire production, tubing, fasteners. | Automotive panels, appliances, metal furniture. |

| Temperature | Performed at room temperature or slightly elevated. | Carried out at room temperature for improved properties. |

| Equipment | Drawing benches, dies, and capstans. | Rolling mills with precise roll gap adjustment. |

Introduction to Metal Forming: Drawing vs Cold Rolling

Drawing and cold rolling are fundamental metal forming processes that shape metals by plastic deformation without altering their chemical composition. Drawing involves pulling metal through a die to reduce its diameter and increase length, enhancing tensile strength and surface finish. Cold rolling compresses metal between rollers at room temperature, improving mechanical properties like hardness and dimensional accuracy while producing smooth, uniform sheets or strips.

Overview of the Drawing Process

The drawing process involves pulling a metal workpiece through a die to reduce its diameter and improve surface finish, resulting in enhanced mechanical properties such as increased tensile strength and hardness. This process is widely used for producing wires, rods, and tubes with precise dimensions and smooth surfaces. Unlike cold rolling, which compresses metal between rollers, drawing primarily relies on tensile forces to shape materials.

Fundamentals of Cold Rolling

Cold rolling is a metalworking process that reduces the thickness of a metal sheet by passing it through rollers at room temperature, enhancing its strength and surface finish through strain hardening. Unlike drawing, which involves pulling metal through a die to change its shape and size, cold rolling primarily improves dimensional tolerances and mechanical properties without significantly altering the cross-sectional shape. The fundamentals of cold rolling include controlling rolling speed, roll gap, and lubrication to optimize metal deformation and achieve desired material characteristics.

Key Differences Between Drawing and Cold Rolling

Drawing primarily involves pulling a metal through a die to reduce its cross-sectional area, enhancing tensile strength and surface finish, whereas cold rolling compresses metal sheets or strips between rollers to achieve thickness reduction and improve mechanical properties. Drawing is typically used for wires, rods, and bars with precise dimensions, while cold rolling is applied to flat products like sheets and strips, impacting thickness uniformity and grain structure. The key differences lie in the deformation mode--tensile versus compressive--and the types of products each process optimally produces.

Mechanical Properties Affected by Each Process

Cold rolling enhances mechanical properties such as yield strength, tensile strength, and hardness by refining the grain structure and inducing strain hardening. Drawing primarily improves tensile strength and elongation through plastic deformation, resulting in increased ductility and surface finish quality. Both processes influence residual stress distribution differently, with cold rolling typically generating compressive stresses that improve fatigue resistance, while drawing may introduce tensile stresses that require subsequent treatment.

Surface Finish Comparison: Drawing and Cold Rolling

Drawing produces a smoother surface finish with finer texture due to the gradual plastic deformation and minimal surface contact during the process, making it ideal for applications requiring high aesthetic quality. Cold rolling results in a harder surface with a more uniform texture but may exhibit minor surface defects such as grooves or scale, which can be reduced through subsequent finishing processes. Both methods improve surface finish compared to hot rolling, yet drawing typically achieves superior surface quality for precision metal components.

Common Applications of Drawing

Drawing is primarily used in manufacturing precision components such as wires, tubes, and bars for automotive, aerospace, and electronics industries due to its ability to produce fine, smooth finishes and maintain tight dimensional tolerances. Cold rolling is commonly applied in producing sheet metal and strips for appliances, construction materials, and packaging, where improved surface finish and mechanical strength are required. Drawing excels in applications needing enhanced mechanical properties and detailed cross-sectional shapes, making it essential for high-strength fasteners and intricate metal parts.

Typical Uses for Cold Rolling

Cold rolling is predominantly used in manufacturing applications that require high precision and superior surface finish, such as automotive panels, appliances, and metal furniture. This process enhances mechanical properties by increasing strength and hardness through strain hardening, making it ideal for producing sheets and strips with tight tolerances. Compared to drawing, cold rolling efficiently produces flat products with uniform thickness, suitable for further fabrication and coating processes.

Advantages and Disadvantages of Each Technique

Drawing produces high-precision components with superior surface finish and tight dimensional tolerances, ideal for complex shapes but often involves higher tool wear and slower production rates. Cold rolling enhances material strength through strain hardening and creates uniform thickness with excellent surface quality, yet it may cause residual stresses and requires significant force, limiting material thickness reduction. Both methods improve mechanical properties, but selection depends on specific application requirements like shape complexity, production volume, and desired material characteristics.

Choosing the Right Process: Factors to Consider

Choosing between drawing and cold rolling depends on factors such as the desired surface finish, dimensional accuracy, and material type. Drawing is ideal for producing complex shapes with high precision and smooth finishes, while cold rolling is preferred for achieving uniform thickness and enhancing mechanical properties. Consider production volume, equipment availability, and cost efficiency to select the most suitable metal forming process.

Drawing Infographic

libterm.com

libterm.com