Reaming is a precision machining process used to enlarge and finish holes to exact dimensions with smooth surface finishes. It improves the accuracy and quality of drilled holes in metalworking and manufacturing, ensuring proper fit for fasteners and components. Discover how reaming techniques can enhance your machining projects by exploring the full article.

Table of Comparison

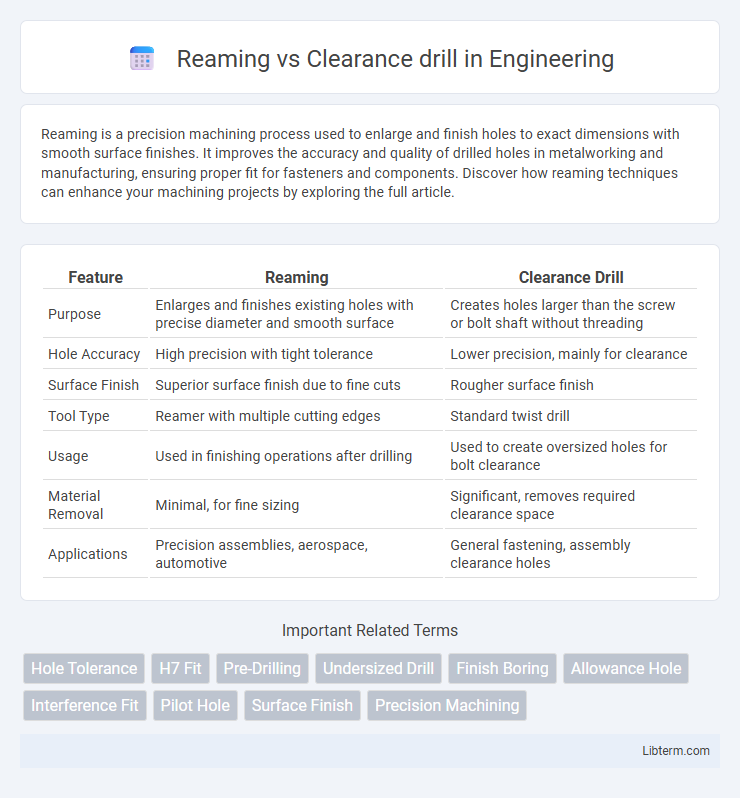

| Feature | Reaming | Clearance Drill |

|---|---|---|

| Purpose | Enlarges and finishes existing holes with precise diameter and smooth surface | Creates holes larger than the screw or bolt shaft without threading |

| Hole Accuracy | High precision with tight tolerance | Lower precision, mainly for clearance |

| Surface Finish | Superior surface finish due to fine cuts | Rougher surface finish |

| Tool Type | Reamer with multiple cutting edges | Standard twist drill |

| Usage | Used in finishing operations after drilling | Used to create oversized holes for bolt clearance |

| Material Removal | Minimal, for fine sizing | Significant, removes required clearance space |

| Applications | Precision assemblies, aerospace, automotive | General fastening, assembly clearance holes |

Introduction to Reaming and Clearance Drilling

Reaming improves hole accuracy and surface finish by slightly enlarging and smoothing pre-drilled holes with a multi-edged cutting tool, ensuring precise dimensions. Clearance drilling involves creating holes with slightly larger diameters to provide space for fasteners or tools, preventing friction and interference during assembly. Both processes are essential for manufacturing parts with tight tolerances and reliable fitment in mechanical assemblies.

Purpose and Functions of Reaming

Reaming is primarily used to improve the dimensional accuracy and surface finish of an existing hole, ensuring precise tolerance and smoothness necessary for tight-fitting assemblies. Unlike clearance drills, which create holes slightly larger to allow free movement of fasteners, reaming enlarges and refines drilled holes without removing excessive material. This process enhances hole quality for applications requiring high precision, such as in aerospace and automotive manufacturing.

Purpose and Applications of Clearance Drilling

Clearance drills are specifically designed to create a hole size that allows a fastener, such as a bolt or screw, to pass through freely without threading into the material, ensuring proper alignment and fit during assembly. These drills are commonly applied in manufacturing and construction industries where precise hole dimensions are critical for joining components, especially in metal fabrication and structural assemblies. Their purpose focuses on enabling smooth bolt insertion and preventing damage to internal threads, making them essential for applications requiring accurate clearance for fastening hardware.

Key Differences Between Reaming and Clearance Drilling

Reaming involves enlarging an existing hole to achieve a precise diameter and smooth finish, whereas clearance drilling creates a hole slightly larger than a bolt or screw to provide clearance for easy assembly. Reaming tools have cutting edges designed for precision and surface finish, while clearance drills prioritize speed and hole clearance without strict dimensional tolerance. The key differences include purpose, dimensional accuracy, and finish quality, with reaming targeting exact tolerances and clearance drilling focusing on fit and ease of part alignment.

Tooling Used in Reaming vs Clearance Drilling

Reaming uses specialized reamers designed with multiple cutting edges and precise tolerances to enlarge holes with high accuracy and smooth finishes, typically requiring slower speeds and careful alignment. Clearance drilling employs standard drill bits focused on creating holes larger than fastener diameters, prioritizing speed and chip evacuation over precision surface finish. The tooling difference lies in reamers' rigid construction and cutting geometry for dimensional accuracy versus clearance drills' simpler, more robust design optimized for rapid material removal.

Material Removal and Hole Precision

Reaming provides superior hole precision by removing a minimal amount of material to achieve an exact diameter and smooth surface finish, making it ideal for finishing drilled holes. Clearance drills remove more material with less precision, primarily creating clearance holes for fasteners, resulting in a rougher hole diameter with wider tolerances. The controlled material removal in reaming ensures tighter dimensional accuracy, whereas clearance drilling prioritizes fast and efficient hole creation.

Surface Finish: Reaming vs Clearance Drilling

Reaming produces a superior surface finish by removing minimal material and creating precise hole dimensions with smooth walls, ideal for finishing pre-drilled holes. Clearance drilling results in rougher surfaces due to larger material removal and lack of cutting precision, leading to less accurate hole sizes and more tool marks. Optimizing for surface finish requires choosing reaming when tight tolerances and smoothness are critical, while clearance drilling suits applications prioritizing speed over finish quality.

Common Industries and Use Cases

Reaming tools are widely used in the automotive and aerospace industries for precision hole finishing, ensuring tight tolerances and smooth surface finishes in engine components and structural assemblies. Clearance drills are essential in manufacturing sectors like metal fabrication and electronics, where they create oversize holes for fastener clearance, allowing proper alignment and assembly of parts. Both tools play critical roles in construction, machinery, and tooling industries for optimizing assembly performance and product durability.

Factors to Consider When Choosing Reaming or Clearance Drilling

Selecting between reaming and clearance drilling depends on factors such as the desired hole tolerance, surface finish, and material hardness. Reaming is preferable for achieving precise dimensions and smooth finishes, especially in softer metals, while clearance drilling suits applications where rapid material removal is needed without stringent accuracy. Tool rigidity, machine capability, and production volume also influence the choice to optimize machining efficiency and part quality.

Summary and Best Practices for Hole Making

Reaming provides high precision and smooth surface finishes by enlarging existing holes with minimal tolerance deviation, making it ideal for final hole sizing in metalworking. Clearance drills create clearance holes allowing fasteners or bolts to pass through, focusing on drill speed and burr-free edges for assembly efficiency. Best practices for hole making include selecting reaming for tight tolerance finishes and clearance drills for fast, clean passages, using proper cutting fluids, and maintaining sharp tooling to enhance accuracy and extend tool life.

Reaming Infographic

libterm.com

libterm.com