Plug flow and continuous stirred-tank reactors (CSTR) represent two fundamental types of chemical reactors, each with distinct flow patterns and mixing characteristics. Plug flow reactors maintain a unidirectional flow with no back-mixing, ensuring that reaction mixture elements move through the reactor as plugs, whereas CSTRs provide complete mixing, resulting in uniform composition throughout the reactor volume. Explore the detailed comparison of these reactor types to optimize your process design and performance.

Table of Comparison

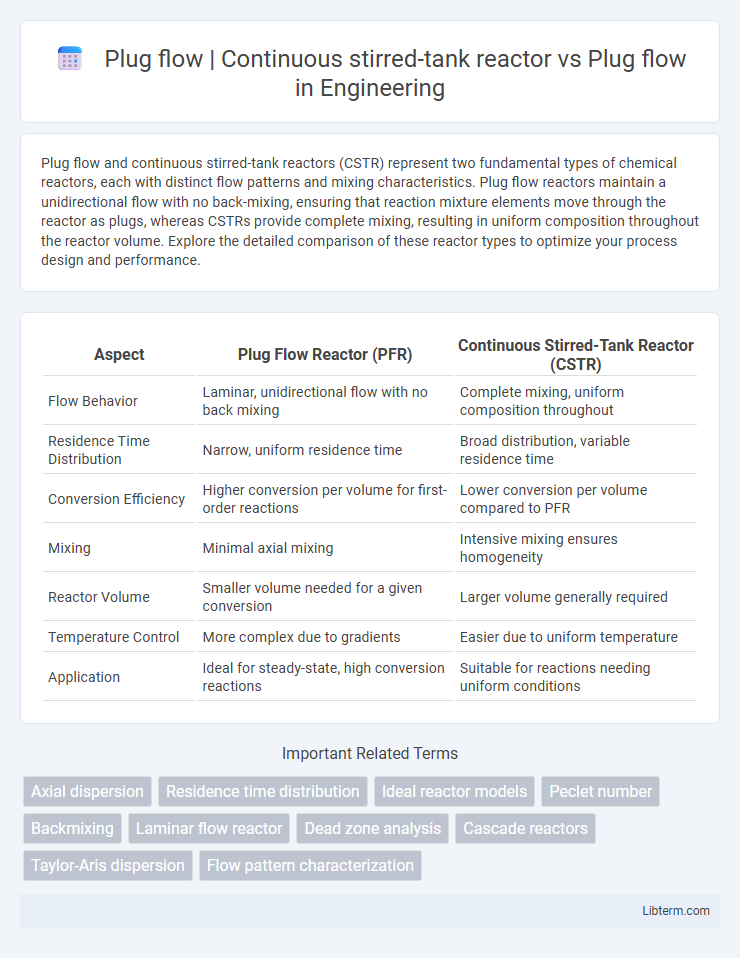

| Aspect | Plug Flow Reactor (PFR) | Continuous Stirred-Tank Reactor (CSTR) |

|---|---|---|

| Flow Behavior | Laminar, unidirectional flow with no back mixing | Complete mixing, uniform composition throughout |

| Residence Time Distribution | Narrow, uniform residence time | Broad distribution, variable residence time |

| Conversion Efficiency | Higher conversion per volume for first-order reactions | Lower conversion per volume compared to PFR |

| Mixing | Minimal axial mixing | Intensive mixing ensures homogeneity |

| Reactor Volume | Smaller volume needed for a given conversion | Larger volume generally required |

| Temperature Control | More complex due to gradients | Easier due to uniform temperature |

| Application | Ideal for steady-state, high conversion reactions | Suitable for reactions needing uniform conditions |

Introduction to Chemical Reactors

Plug flow reactors (PFRs) and continuous stirred-tank reactors (CSTRs) are fundamental types of chemical reactors used in industrial processes. PFRs feature a flow pattern where reactants move through the reactor as a "plug," maintaining concentration gradients along the flow path, ideal for reactions requiring precise residence times and minimal back-mixing. In contrast, CSTRs ensure uniform reactant composition throughout the reactor volume by constant stirring, making them suitable for reactions with slower kinetics and complex mixing requirements.

Overview of Plug Flow Reactor (PFR)

Plug Flow Reactors (PFRs) maintain a unidirectional flow where reactants move through the reactor as a plug with minimal axial mixing, ensuring a concentration gradient along the reactor length. This design contrasts with Continuous Stirred-Tank Reactors (CSTRs), which provide complete mixing and uniform concentration throughout the reactor volume. PFRs offer higher conversion efficiency per reactor volume in reactions with favorable kinetics, making them ideal for continuous production processes in chemical engineering.

Overview of Continuous Stirred-Tank Reactor (CSTR)

Continuous Stirred-Tank Reactors (CSTRs) maintain homogeneous mixing through continuous agitation, ensuring uniform temperature and concentration throughout the reactor volume. Unlike Plug Flow Reactors (PFRs) where reactants flow in a unidirectional plug without back-mixing, CSTRs allow complete mixing, resulting in outlet concentrations equal to the reactor's internal concentration. This mixing characteristic influences reaction kinetics, making CSTRs suitable for processes requiring steady-state operation and consistent product quality.

Key Differences: Plug Flow vs CSTR

Plug flow reactors (PFR) maintain a unidirectional flow where reactants move as a plug with no back-mixing, resulting in concentration gradients along the reactor length, ideal for reactions requiring precise residence time control. Continuous stirred-tank reactors (CSTR) operate with complete mixing, ensuring uniform composition throughout the reactor but leading to lower conversion per volume compared to PFR. Key differences include PFR's higher conversion efficiency for first-order reactions and CSTR's ease of temperature control and handling of variable feed conditions.

Flow Patterns and Mixing Behavior

Plug flow reactors (PFRs) exhibit a unidirectional flow pattern with minimal axial mixing, ensuring that fluid elements move in discrete "plugs" with uniform residence times, optimizing reaction efficiency for certain kinetic regimes. Continuous stirred-tank reactors (CSTRs) feature complete mixing within the reactor volume, resulting in uniform composition throughout but variable residence times and lower conversion per unit volume for many reactions. The distinct flow and mixing behaviors impact reactor design and performance; PFRs maintain concentration gradients along the reactor length, while CSTRs achieve homogeneity, influencing reaction rates and product distribution.

Reaction Kinetics in PFR and CSTR

Plug flow reactors (PFR) exhibit spatial concentration and temperature gradients, leading to higher reactant conversion per unit volume compared to continuous stirred-tank reactors (CSTR) with identical kinetics and volume. Reaction kinetics in PFR are modeled by differential equations describing concentration changes along the reactor length, allowing for optimal handling of fast reactions and minimizing back-mixing effects. In contrast, CSTRs maintain uniform concentration via complete mixing, leading to lower conversion in first-order reactions under equal conditions as reaction rates are governed by the reactor's bulk concentration.

Conversion Efficiency Comparison

Plug flow reactors (PFR) exhibit higher conversion efficiency compared to continuous stirred-tank reactors (CSTR) due to their characteristic of maintaining a concentration gradient along the reactor length, which maximizes reactant utilization. In PFRs, reactants experience a unidirectional flow with minimal back-mixing, leading to near-complete conversion in a single pass, whereas CSTRs rely on complete mixing that results in uniform concentration and lower overall conversion per volume. Conversion efficiency in PFRs often surpasses that of CSTRs, especially in first-order reactions, making them preferable for processes requiring high throughput and reaction completeness.

Industrial Applications: PFR vs CSTR

Plug flow reactors (PFR) are ideal for industrial applications requiring high conversion per unit volume, such as petrochemical cracking and polymerization, due to their efficient handling of reaction kinetics and minimal back-mixing. Continuous stirred-tank reactors (CSTR) excel in processes demanding uniform composition throughout the reactor, like continuous fermentation and wastewater treatment, where thorough mixing ensures consistent product quality. The choice between PFR and CSTR depends on factors like reaction rate, thermal control, and desired selectivity, impacting productivity and operational costs in large-scale chemical manufacturing.

Advantages and Disadvantages of Each Reactor

Plug flow reactors (PFR) offer high conversion rates per volume due to their streamlined flow and minimal back-mixing, making them ideal for large-scale, continuous chemical processes with reaction-limited kinetics. Continuous stirred-tank reactors (CSTR) provide excellent mixing and uniform composition throughout the reactor, favoring reactions requiring temperature control and handling of catalysts, but generally exhibit lower conversion per volume and possible dilution effects. PFR advantages include better efficiency for ideal plug flow and cost-effective designs, while disadvantages involve difficulty in temperature and concentration control; CSTR advantages encompass easy control and flexibility, with disadvantages such as lower conversion efficiency and larger reactor volume requirements.

Selecting the Optimal Reactor Type

Selecting the optimal reactor type between plug flow and continuous stirred-tank reactors (CSTR) depends on reaction kinetics and desired conversion efficiency. Plug flow reactors offer higher conversion per volume for first-order reactions due to minimal back-mixing, while CSTRs provide uniform composition and temperature, ideal for reactions requiring thorough mixing. Evaluating factors such as residence time distribution, scale-up feasibility, and heat transfer requirements ensures the appropriate reactor choice for maximizing productivity and process control.

Plug flow | Continuous stirred-tank reactor Infographic

libterm.com

libterm.com