The Unified Thread Standard (UTS) defines a set of standardized screw thread profiles commonly used in the United States and Canada, ensuring compatibility across a wide range of fasteners and components. It specifies thread angles, pitch, and diameters that help maintain consistent quality and interchangeability in mechanical assemblies. Explore the rest of the article to understand how UTS impacts your projects and the key details behind its specifications.

Table of Comparison

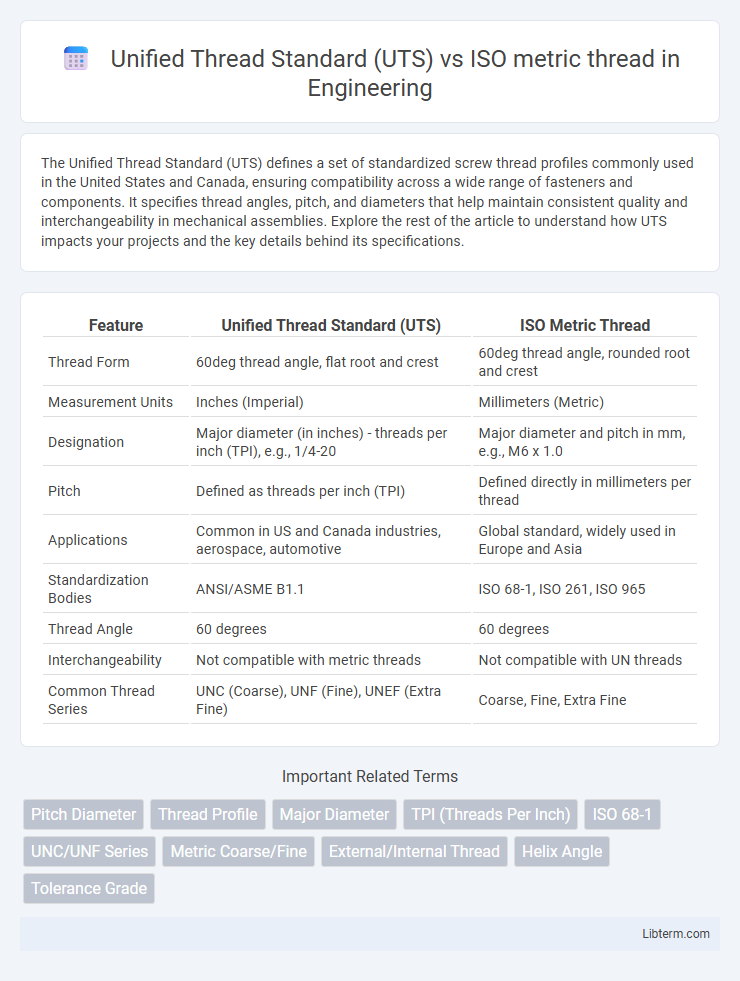

| Feature | Unified Thread Standard (UTS) | ISO Metric Thread |

|---|---|---|

| Thread Form | 60deg thread angle, flat root and crest | 60deg thread angle, rounded root and crest |

| Measurement Units | Inches (Imperial) | Millimeters (Metric) |

| Designation | Major diameter (in inches) - threads per inch (TPI), e.g., 1/4-20 | Major diameter and pitch in mm, e.g., M6 x 1.0 |

| Pitch | Defined as threads per inch (TPI) | Defined directly in millimeters per thread |

| Applications | Common in US and Canada industries, aerospace, automotive | Global standard, widely used in Europe and Asia |

| Standardization Bodies | ANSI/ASME B1.1 | ISO 68-1, ISO 261, ISO 965 |

| Thread Angle | 60 degrees | 60 degrees |

| Interchangeability | Not compatible with metric threads | Not compatible with UN threads |

| Common Thread Series | UNC (Coarse), UNF (Fine), UNEF (Extra Fine) | Coarse, Fine, Extra Fine |

Introduction to Thread Standards

Unified Thread Standard (UTS) and ISO Metric Thread are two predominant thread standards used globally for screws and bolts, with UTS primarily applied in the United States and ISO Metric threads widely adopted internationally. UTS features thread profiles with a 60-degree angle and specific thread pitch measured in threads per inch (TPI), whereas ISO Metric threads use a 60-degree angle as well but are defined by pitch in millimeters. Understanding these standards is crucial for ensuring compatibility and interchangeability in manufacturing and mechanical assemblies across different regions.

Overview of Unified Thread Standard (UTS)

Unified Thread Standard (UTS) is a thread form commonly used in the United States and Canada for fasteners, characterized by a 60-degree thread angle and specific pitch and diameter designations such as UNC (coarse) and UNF (fine). It provides standardized thread profiles and dimensions for bolts, screws, and nuts, ensuring compatibility and interchangeability in manufacturing and assembly processes. Unlike the ISO metric thread system, UTS threads are specified in inches rather than millimeters, reflecting their imperial measurement origins.

Introduction to ISO Metric Thread

ISO metric thread, standardized globally by the International Organization for Standardization (ISO), features a 60-degree thread angle and symmetrical thread profile designed for consistent strength and ease of manufacturing. Unlike the Unified Thread Standard (UTS), which is primarily used in the United States and Canada with inch-based measurements, ISO metric threads utilize metric dimensions for pitch and diameter, facilitating international compatibility. These threads are commonly employed in automotive, aerospace, and machinery industries where precise mechanical fastening is essential.

Historical Development and Adoption

The Unified Thread Standard (UTS) emerged in the 1940s as a collaborative effort among the United States, Canada, and the United Kingdom to unify multiple thread standards into a common system, primarily used in North America for inch-based fasteners. In contrast, the ISO metric thread was introduced by the International Organization for Standardization in 1947, gaining widespread global adoption due to its metric dimensioning and simpler design features tailored for international manufacturing industries. The historical development of UTS reflects regional industrial cooperation, while ISO metric threads symbolize the globalization and standardization of engineering practices across diverse countries.

Dimensional Differences: UTS vs ISO Metric

Unified Thread Standard (UTS) and ISO Metric threads differ primarily in their dimensional specifications, with UTS threads measured in inches and ISO Metric threads measured in millimeters. UTS thread pitch is defined by threads per inch (TPI), whereas ISO Metric uses the distance between threads in millimeters, often resulting in finer thread pitches. The thread angle also varies: UTS threads have a 60-degree flank angle similar to ISO Metric, but the thread profiles and tolerance standards create distinct dimensional compatibility issues between the two systems.

Pitch and Profile Comparisons

Unified Thread Standard (UTS) threads have a 60-degree thread angle with a flat crest and root, while ISO metric threads also feature a 60-degree angle but with rounded crests and roots, providing different stress distributions. Pitch for UTS threads is measured in threads per inch (TPI), commonly ranging from coarse (e.g., 20 TPI for 1/4-inch diameter) to fine pitches, whereas ISO metric threads use the pitch in millimeters (e.g., 1.0 mm for an M6 screw). These profile and pitch differences impact compatibility and application, with UTS mainly used in the United States and ISO metric threads prevalent in international standards.

Applications and Industry Preferences

Unified Thread Standard (UTS) is predominantly used in North American manufacturing industries, especially in automotive, aerospace, and machinery applications requiring inch-based screw threads. ISO metric threads dominate global markets, favored in Europe, Asia, and international construction and consumer electronics sectors due to their metric measurement system and standardization. Industry preferences hinge on regional standards, with UTS preferred for legacy equipment and ISO metric threads chosen for compatibility in modern, globally integrated supply chains.

Interchangeability and Compatibility Issues

Unified Thread Standard (UTS) and ISO metric thread systems differ in thread angle, pitch, and designation, leading to limited interchangeability and potential compatibility issues. UTS uses a 60-degree thread angle with threads per inch (TPI), while ISO metric threads use millimeter pitch, causing mismatched fit and improper engagement when mixed. Mixing UTS and ISO components can result in mechanical failure, leaks, or damage due to differences in thread form and tolerance.

Advantages and Disadvantages of Each Standard

Unified Thread Standard (UTS) offers widespread use in North America with compatibility across many industrial applications, featuring inch-based measurements and ease of sourcing fasteners. ISO metric threads dominate globally with internationally recognized dimensions and thread profiles, providing better tensile strength and uniformity in multi-national manufacturing. UTS may pose challenges in global supply and conversion, while ISO metric threads can complicate compatibility with American-made equipment designed for UTS fasteners.

Choosing the Right Thread Standard for Your Project

Choosing the right thread standard for your project depends on factors such as geographic location, application requirements, and compatibility with existing hardware. Unified Thread Standard (UTS) is widely used in the United States and Canada, offering inches-based thread sizes and pitch, while ISO metric threads are preferred internationally, providing millimeter-based dimensions and a broader range of pitch options. Selecting the proper thread standard ensures optimal fit, ease of sourcing components, and compliance with industry regulations.

Unified Thread Standard (UTS) Infographic

libterm.com

libterm.com