Ductility refers to a material's ability to undergo significant plastic deformation before rupture, allowing it to be stretched into wire or thin sheets without breaking. High ductility enhances the flexibility and toughness of metals, making them ideal for manufacturing and construction applications. Discover how understanding ductility can improve your material selection and project outcomes in the rest of this article.

Table of Comparison

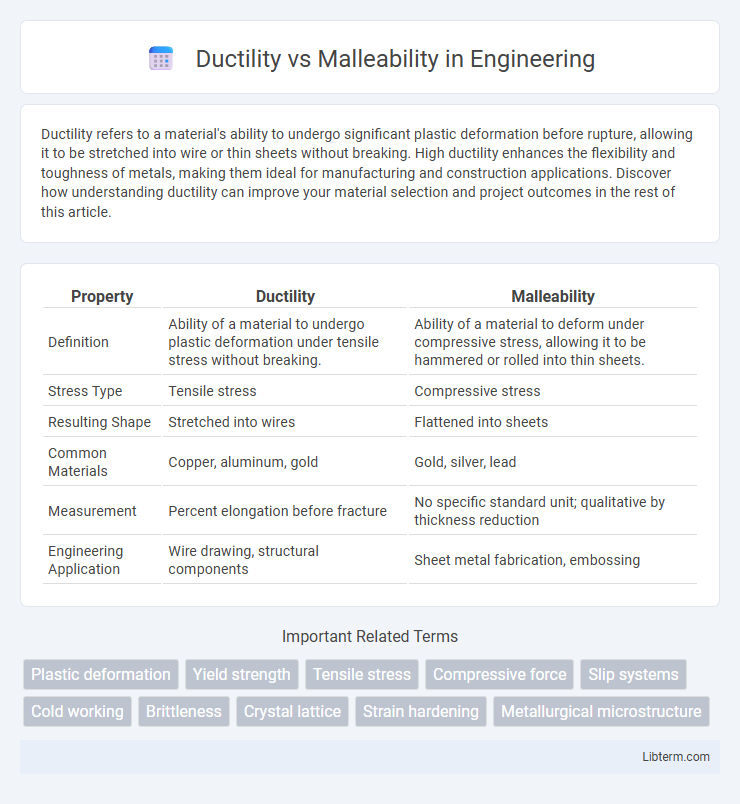

| Property | Ductility | Malleability |

|---|---|---|

| Definition | Ability of a material to undergo plastic deformation under tensile stress without breaking. | Ability of a material to deform under compressive stress, allowing it to be hammered or rolled into thin sheets. |

| Stress Type | Tensile stress | Compressive stress |

| Resulting Shape | Stretched into wires | Flattened into sheets |

| Common Materials | Copper, aluminum, gold | Gold, silver, lead |

| Measurement | Percent elongation before fracture | No specific standard unit; qualitative by thickness reduction |

| Engineering Application | Wire drawing, structural components | Sheet metal fabrication, embossing |

Introduction to Ductility and Malleability

Ductility refers to a material's ability to undergo significant plastic deformation before rupture, allowing it to be stretched into a wire without breaking. Malleability describes a material's capacity to deform under compressive stress, enabling it to be hammered or rolled into thin sheets. Both properties are critical in materials science for assessing metal performance in manufacturing and structural applications.

Defining Ductility: Meaning and Examples

Ductility refers to a material's ability to undergo significant plastic deformation under tensile stress, allowing it to be stretched into thin wires without breaking. Common examples include metals like copper and aluminum, which exhibit high ductility essential for electrical wiring and metal fabrication. This property is critical in industries requiring materials that can absorb energy and deform without fracturing under tension.

Understanding Malleability: Concept and Illustrations

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. Metals like gold and copper exhibit high malleability, making them ideal for applications such as jewelry and industrial shaping processes. Understanding malleability helps in selecting materials for manufacturing tasks requiring bending and shaping without fracture.

Key Differences Between Ductility and Malleability

Ductility measures a material's ability to undergo significant plastic deformation under tensile stress, allowing it to be stretched into thin wires without breaking, while malleability refers to a material's capability to deform under compressive stress, enabling it to be hammered or rolled into thin sheets. Metals like copper exhibit high ductility, making them ideal for electrical wiring, whereas gold demonstrates exceptional malleability, suitable for intricate jewelry shaping. The primary difference lies in ductility involving tensile forces and elongation, whereas malleability involves compressive forces and surface deformation.

Atomic Structure and Its Impact on Ductility and Malleability

Ductility and malleability arise from the atomic structure and metallic bonding of materials, where atoms can slide past each other without breaking bonds. In ductile materials, such as copper, atomic layers can deform under tensile stress due to the presence of numerous slip systems in their crystal lattice. Malleability is influenced by atomic arrangements that allow atoms to shift under compressive stress, enabling metals like gold to deform into thin sheets without fracturing.

Common Materials: Which Are Ductile, Which Are Malleable?

Copper, aluminum, and gold are highly ductile metals known for their ability to be stretched into thin wires without breaking, essential for electrical wiring and jewelry making. Gold, silver, and lead exhibit remarkable malleability, allowing them to be hammered or rolled into thin sheets, useful in coinage and decorative arts. Steel and iron balance moderate ductility and malleability, making them versatile for construction and manufacturing where both properties are advantageous.

Industrial Applications of Ductile and Malleable Materials

Ductility, the ability of a material to undergo significant plastic deformation before rupture, is essential in industries like automotive and aerospace for manufacturing wires, cables, and structural components that require flexibility and tensile strength. Malleability, the capacity to be hammered or rolled into thin sheets without cracking, is crucial in metal forming processes such as forging and sheet metal fabrication used in construction, jewelry, and packaging. Both ductile materials like copper and aluminum and malleable materials like gold and lead play pivotal roles in enhancing product durability and manufacturability across diverse industrial applications.

Factors Affecting Ductility and Malleability in Metals

Ductility in metals is primarily influenced by factors such as temperature, grain size, and alloy composition, where higher temperatures and finer grains typically enhance the ability to undergo plastic deformation without fracture. Malleability, on the other hand, depends significantly on the metal's crystal structure and bonding strength, with metals like gold and silver exhibiting high malleability due to their face-centered cubic (FCC) crystal lattice and weaker metallic bonds. Impurities and work hardening reduce both ductility and malleability by restricting dislocation movement, which limits the metal's capacity to deform under tensile and compressive stresses.

Testing Methods for Ductility and Malleability

Ductility is commonly tested using a tensile test that measures a material's ability to deform plastically under tensile stress before breaking, with elongation and reduction of area as key parameters. Malleability is assessed by compression or flattening tests that evaluate a material's capacity to deform under compressive stress without cracking, focusing on the extent to which the material can be hammered or rolled into thin sheets. Both tests provide critical data for engineering applications, helping determine suitability for processes like forging, rolling, and wire drawing.

Importance of Ductility and Malleability in Material Selection

Ductility and malleability are critical properties in material selection, determining how materials deform under stress without breaking. High ductility is essential for applications requiring materials to withstand tensile forces, such as in wire manufacturing, while malleability is vital for processes involving compressive forces like metal forming and shaping. Selecting materials with appropriate ductility and malleability enhances structural integrity, manufacturability, and performance in engineering and industrial applications.

Ductility Infographic

libterm.com

libterm.com