Feedforward control anticipates disturbances by adjusting system inputs before errors occur, enhancing overall process stability and performance. It relies on accurate models and measurements to predict changes, making it ideal for maintaining desired output despite varying conditions. Explore this article to understand how implementing feedforward control can optimize Your system's efficiency and reliability.

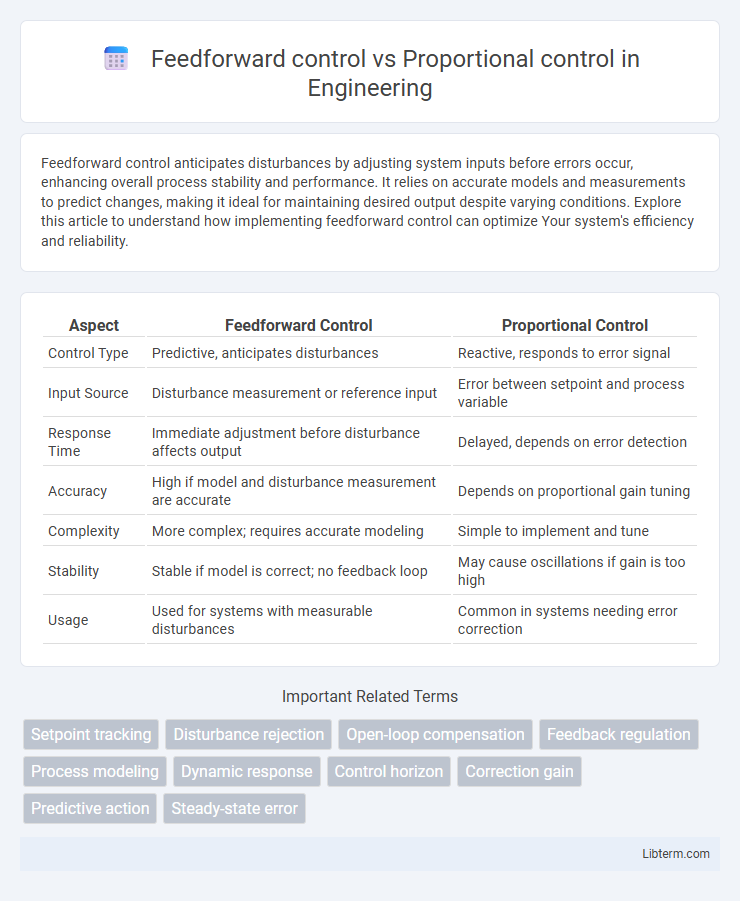

Table of Comparison

| Aspect | Feedforward Control | Proportional Control |

|---|---|---|

| Control Type | Predictive, anticipates disturbances | Reactive, responds to error signal |

| Input Source | Disturbance measurement or reference input | Error between setpoint and process variable |

| Response Time | Immediate adjustment before disturbance affects output | Delayed, depends on error detection |

| Accuracy | High if model and disturbance measurement are accurate | Depends on proportional gain tuning |

| Complexity | More complex; requires accurate modeling | Simple to implement and tune |

| Stability | Stable if model is correct; no feedback loop | May cause oscillations if gain is too high |

| Usage | Used for systems with measurable disturbances | Common in systems needing error correction |

Introduction to Control Systems

Feedforward control anticipates disturbances by adjusting the control input based on measured variables before the process output deviates. Proportional control reacts to the error between the desired setpoint and the actual output, providing corrective action proportional to this error. In control systems, feedforward control enhances performance by reducing delay, while proportional control ensures stability by continuously correcting errors.

Defining Feedforward Control

Feedforward control anticipates disturbances by adjusting the control input based on measured changes in the system before the output is affected, enhancing system stability and response speed. Unlike proportional control, which reacts to errors after they occur, feedforward control relies on predictive models to prevent deviations proactively. This approach is essential in processes where delay or lag can compromise performance, such as in temperature regulation and chemical mixing.

Understanding Proportional Control

Proportional control adjusts system output by applying a correction proportional to the current error, enabling real-time response to deviations from the setpoint. This type of control is widely used in industrial automation for its simplicity and effectiveness in reducing steady-state error. Unlike feedforward control, which anticipates disturbances, proportional control relies solely on feedback to maintain system stability and accuracy.

Key Differences Between Feedforward and Proportional Control

Feedforward control anticipates disturbances by adjusting the control input based on measured variables before the output is affected, while proportional control reacts to the error between the desired setpoint and the actual output. Feedforward control improves system stability and response time by preventing deviations, whereas proportional control reduces steady-state error but may cause oscillations due to its reactive nature. The primary difference lies in feedforward's predictive adjustment versus proportional control's error-based correction.

Working Principles of Feedforward Control

Feedforward control operates by anticipating disturbances and adjusting the control input before the process variable deviates from the setpoint, relying on a predictive model of the system. Unlike proportional control, which reacts according to the error between the setpoint and the process variable, feedforward control uses measured disturbance inputs to maintain system stability proactively. This predictive adjustment enhances system responsiveness and reduces lag, improving overall control accuracy.

Working Principles of Proportional Control

Proportional control operates by continuously adjusting the control output in direct proportion to the error, which is the difference between the setpoint and the process variable. The controller multiplies this error by a proportional gain to generate a corrective signal, aiming to reduce the error to zero. This method inherently introduces a steady-state error, known as offset, which requires tuning or supplemental control strategies to eliminate.

Advantages of Feedforward Control

Feedforward control enhances system responsiveness by anticipating disturbances before they affect the process, resulting in improved stability and reduced error compared to proportional control. It provides faster correction without waiting for feedback signals, which minimizes overshoot and system lag. This predictive capability is particularly beneficial in complex or rapidly changing environments where precise control is critical.

Benefits of Proportional Control

Proportional control offers precise adjustment by continuously correcting the error between the setpoint and the process variable, improving system stability and response time. It reduces steady-state error and minimizes oscillations in processes like temperature regulation or speed control, enhancing overall performance. Proportional control is simpler to implement and requires less system modeling compared to feedforward control, making it cost-effective and reliable in diverse industrial applications.

Limitations and Challenges of Each Method

Feedforward control struggles with uncertainties and requires an accurate model of the system, making it less effective when disturbances are unknown or unpredictable. Proportional control faces limitations in steady-state error and can cause oscillations or instability if gains are not properly tuned. Both methods demand careful calibration, with feedforward control heavily dependent on system modeling accuracy and proportional control sensitive to parameter variation and external disturbances.

Choosing the Right Control Strategy

Selecting the appropriate control strategy between feedforward control and proportional control depends on system dynamics and disturbance predictability. Feedforward control excels in managing measurable disturbances by anticipating changes and adjusting inputs proactively, reducing lag and improving stability. Proportional control offers simplicity and robustness for processes with steady-state errors and unknown disturbances, making it suitable when disturbance models are unavailable or uncertain.

Feedforward control Infographic

libterm.com

libterm.com