Hardening enhances your system's security by minimizing vulnerabilities and strengthening defenses against cyber threats. It involves configuring hardware and software to reduce potential attack surfaces and ensure robust protection. Discover effective hardening strategies and how they can safeguard your digital environment in the rest of this article.

Table of Comparison

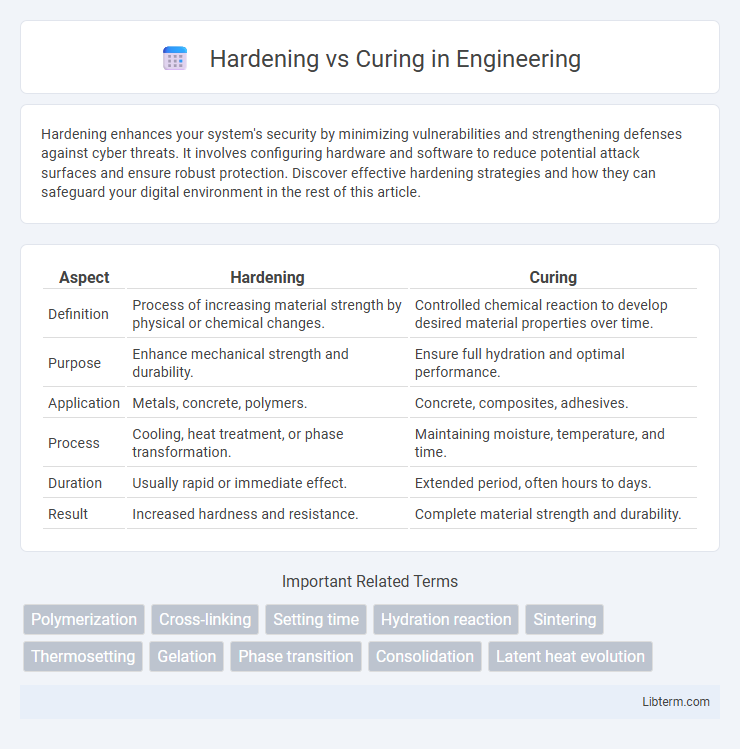

| Aspect | Hardening | Curing |

|---|---|---|

| Definition | Process of increasing material strength by physical or chemical changes. | Controlled chemical reaction to develop desired material properties over time. |

| Purpose | Enhance mechanical strength and durability. | Ensure full hydration and optimal performance. |

| Application | Metals, concrete, polymers. | Concrete, composites, adhesives. |

| Process | Cooling, heat treatment, or phase transformation. | Maintaining moisture, temperature, and time. |

| Duration | Usually rapid or immediate effect. | Extended period, often hours to days. |

| Result | Increased hardness and resistance. | Complete material strength and durability. |

Understanding Hardening and Curing: Key Differences

Hardening refers to the physical process where a material, such as concrete or resin, gains strength and rigidity over time due to drying or cooling, while curing involves chemically treating a substance to achieve optimal durability and performance, often through controlled temperature and humidity. Hardening is primarily a mechanical transformation driven by moisture loss or phase changes, whereas curing is a chemical reaction that can continue internally, enhancing the material's molecular structure. Understanding these differences is crucial in construction and manufacturing sectors to ensure proper material strength and longevity.

The Science Behind Hardening and Curing

Hardening involves a physical change where materials like metals or concrete increase strength through cooling or drying, resulting in improved structural integrity. Curing is a chemical process in which polymers, concrete, or adhesives undergo polymerization or hydration, forming strong molecular bonds that enhance durability and resistance. Both processes are critical for achieving optimal mechanical properties, with hardening focusing on phase transitions and curing emphasizing chemical reactions.

Importance of Hardening in Construction Materials

Hardening in construction materials is a critical process that enhances strength, durability, and resistance to environmental stressors by allowing chemical reactions such as hydration in concrete or polymer cross-linking in resins to take place. Proper hardening ensures load-bearing capacity and longevity, preventing premature failure and structural damage. Optimized hardening directly impacts the safety, performance, and lifespan of buildings and infrastructure projects.

The Role of Curing in Material Performance

Curing significantly impacts material performance by facilitating chemical reactions that enhance strength, durability, and resistance to environmental factors. Unlike hardening, which primarily involves physical changes such as cooling or drying, curing promotes the formation of strong molecular bonds within polymers, concrete, and adhesives. Proper curing ensures optimal mechanical properties and long-term stability in construction materials and composite structures.

Hardening vs Curing: Timing and Processes

Hardening primarily refers to the initial phase in materials like concrete or adhesives where the substance gains sufficient strength to withstand handling, typically occurring within hours to days. Curing encompasses the entire chemical and physical reaction process that continues over days to weeks, ensuring the material achieves full strength and durability. The timing difference is critical: hardening signals early strength gain, while curing ensures long-term performance and stability.

Factors Affecting Hardening and Curing Rates

Hardening and curing rates are influenced by key factors such as temperature, humidity, and material composition. Elevated temperatures accelerate chemical reactions in both processes, while optimal humidity levels prevent premature drying or excess moisture absorption. The presence of additives or admixtures also modifies the microstructure development, directly impacting the speed and quality of hardening and curing.

Common Misconceptions About Hardening and Curing

Hardening and curing are often mistakenly used interchangeably, but hardening refers to the process where a material gains strength over time, while curing involves a chemical reaction that sets or stabilizes the material. Common misconceptions include assuming all materials require curing for hardening to occur, when in reality, some metals harden through heat treatment without a curing phase. Understanding the distinction is critical in industries like concrete construction and polymer manufacturing, where precise terminology impacts quality control and performance outcomes.

Best Practices for Effective Hardening and Curing

Effective hardening and curing require precise control of environmental factors such as temperature, humidity, and time to ensure optimal material strength and durability. Best practices include maintaining consistent curing conditions to prevent premature drying or moisture loss, which can lead to surface defects and reduced performance. Implementing appropriate curing methods, like water curing, steam curing, or using curing compounds, achieves uniform hydration and enhances the overall quality of concrete or resin-based materials.

Comparative Benefits: Hardening vs Curing

Hardening improves the mechanical strength and durability of materials by increasing their resistance to wear and deformation, making it ideal for metals and concrete. Curing, on the other hand, enhances chemical stability and moisture retention, essential for processes like concrete setting and adhesive bonding. Hardening provides immediate surface toughness, while curing ensures long-term structural integrity and optimal performance.

Choosing the Right Method: Hardening or Curing?

Choosing the right method between hardening and curing depends on the material properties and application requirements; hardening typically involves physical changes such as cooling or heat treatment to increase strength, while curing relies on chemical reactions like polymerization or cross-linking to achieve durability. For metals or alloys, hardening processes like quenching and tempering are essential to enhance hardness and wear resistance, whereas for polymers, adhesives, and composites, curing through heat, UV light, or time-dependent chemical reactions ensures long-lasting structural integrity. Evaluating factors like environmental conditions, desired mechanical properties, and processing time helps determine whether hardening or curing is the optimal approach for your project.

Hardening Infographic

libterm.com

libterm.com