Solid materials exhibit a definite shape and volume due to the fixed arrangement of their atoms or molecules. Their structural rigidity results from strong intermolecular forces, making them resistant to deformation under applied stress. Explore the rest of the article to understand how solids differ from liquids and gases and their various applications in everyday life.

Table of Comparison

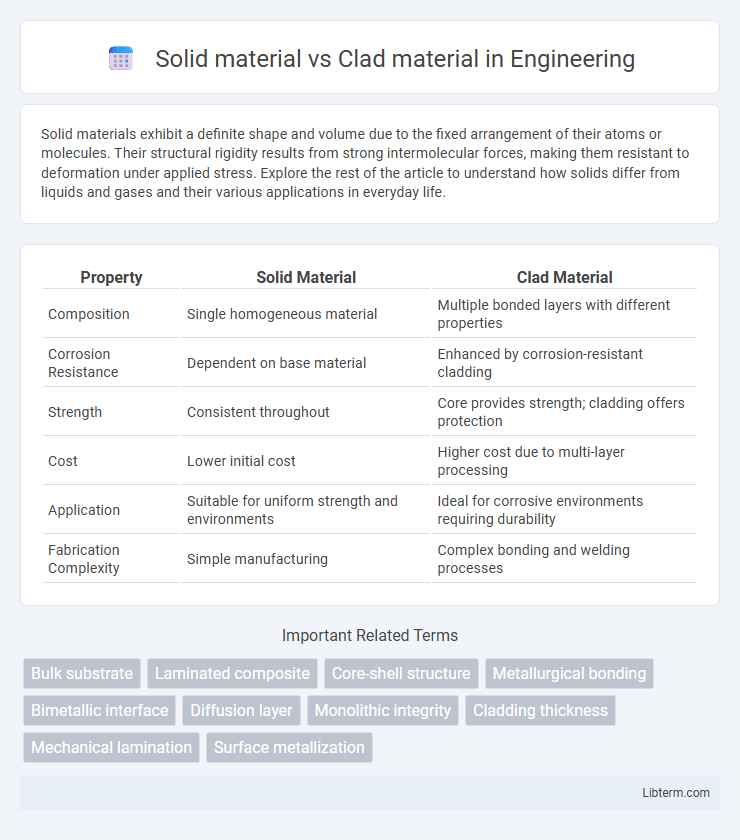

| Property | Solid Material | Clad Material |

|---|---|---|

| Composition | Single homogeneous material | Multiple bonded layers with different properties |

| Corrosion Resistance | Dependent on base material | Enhanced by corrosion-resistant cladding |

| Strength | Consistent throughout | Core provides strength; cladding offers protection |

| Cost | Lower initial cost | Higher cost due to multi-layer processing |

| Application | Suitable for uniform strength and environments | Ideal for corrosive environments requiring durability |

| Fabrication Complexity | Simple manufacturing | Complex bonding and welding processes |

Understanding Solid Materials: Definition and Properties

Solid materials are characterized by a fixed shape and volume due to strong intermolecular forces that hold their particles tightly together, resulting in rigidity and resistance to deformation. They exhibit properties such as high density, low compressibility, and defined melting points, which influence their mechanical strength and thermal conductivity. Understanding these fundamental properties enables engineers and scientists to select appropriate solid materials for applications requiring durability, structural integrity, and stability.

What Are Clad Materials? Structure and Composition

Clad materials consist of two or more bonded layers of different metals designed to combine the advantageous properties of each metal, such as corrosion resistance and strength. The structure typically includes a core metal like aluminum or steel, coated with a thin layer of a more resilient or corrosion-resistant metal, achieved through processes like roll bonding or explosive welding. This layered composition enhances performance in applications where solid materials alone may fail due to environmental or mechanical stress.

Manufacturing Processes: Solid vs Clad Materials

Solid materials in manufacturing involve shaping a single, homogeneous substance through processes like casting, forging, or machining, offering uniform mechanical properties and simpler fabrication. Clad materials combine two or more layers of different metals or alloys through bonding techniques such as roll bonding, explosion welding, or brazing, enhancing properties like corrosion resistance and strength. Manufacturing clad materials requires precise control of interface quality and bonding parameters to ensure structural integrity and performance in demanding applications.

Mechanical Strength Comparison

Solid materials exhibit uniform mechanical strength throughout their volume, providing consistent resistance to deformation and failure under stress. Clad materials combine a high-strength core with a corrosion-resistant or wear-resistant outer layer, enhancing overall durability while optimizing weight and cost. The mechanical strength of clad materials often surpasses that of solid materials by leveraging the superior properties of both layers, especially in applications requiring both toughness and surface protection.

Corrosion Resistance: Solid Material vs Clad Material

Solid materials offer inherent corrosion resistance based on their base alloy composition, often requiring higher-grade metals like stainless steel to withstand harsh environments. Clad materials enhance corrosion resistance by bonding a thin layer of corrosion-resistant metal, such as titanium or nickel alloys, over a less expensive base metal, combining strength and cost-efficiency. The clad layer provides targeted protection against specific corrosive agents, extending the lifespan of components in aggressive chemical or marine settings.

Thermal and Electrical Conductivity Differences

Solid materials typically exhibit uniform thermal and electrical conductivity due to their homogeneous structure, facilitating consistent heat and electron flow. Clad materials combine different metals, resulting in varied conductivity properties where one layer may enhance thermal transfer while the other optimizes electrical performance. This layered approach allows for tailored conductivity characteristics not achievable in single, solid materials, making clad materials ideal for applications requiring balanced thermal and electrical management.

Cost Analysis: Solid Material vs Clad Material

Solid materials generally incur higher raw material costs due to the use of uniform, often more expensive metals throughout the component. Clad materials offer cost advantages by combining an expensive corrosion-resistant surface layer with a less costly structural core, reducing the overall material expense. Evaluating lifecycle costs, clad materials can also provide savings by extending durability and reducing maintenance compared to solid materials.

Typical Applications and Industry Use Cases

Solid materials are widely used in structural components, aerospace parts, and automotive manufacturing due to their uniform properties and high strength. Clad materials find typical applications in corrosion-resistant piping, chemical processing equipment, and marine environments where combining a durable substrate with a protective alloy layer enhances performance. Industries such as oil and gas, petrochemical, and power generation rely heavily on clad materials for critical infrastructure to extend lifespan and reduce maintenance costs.

Environmental Impact and Sustainability Considerations

Solid materials typically have a higher environmental impact due to the extensive extraction and processing required, resulting in increased energy consumption and greenhouse gas emissions. Clad materials offer improved sustainability by combining thin layers of different metals, reducing overall raw material usage and enhancing recyclability. Their layered structure often allows for extended product lifespan and lower resource demand, making clad materials a more eco-friendly choice in manufacturing.

Choosing Between Solid and Clad Materials: Key Factors

Selecting between solid and clad materials depends on factors like durability, corrosion resistance, and cost-efficiency. Solid materials offer uniform strength and are ideal for high-stress applications, while clad materials provide enhanced surface protection with a corrosion-resistant layer bonded to a robust core. Evaluating environmental exposure, mechanical requirements, and budget constraints ensures optimal material performance and longevity.

Solid material Infographic

libterm.com

libterm.com