A centrifugal pump operates by converting rotational kinetic energy from a motor into hydrodynamic energy to move fluids efficiently. Its design, featuring an impeller rotating within a casing, creates centrifugal force that drives fluid outward into the discharge pipe. Explore the details of centrifugal pump types, applications, and maintenance tips in the rest of the article to optimize your system's performance.

Table of Comparison

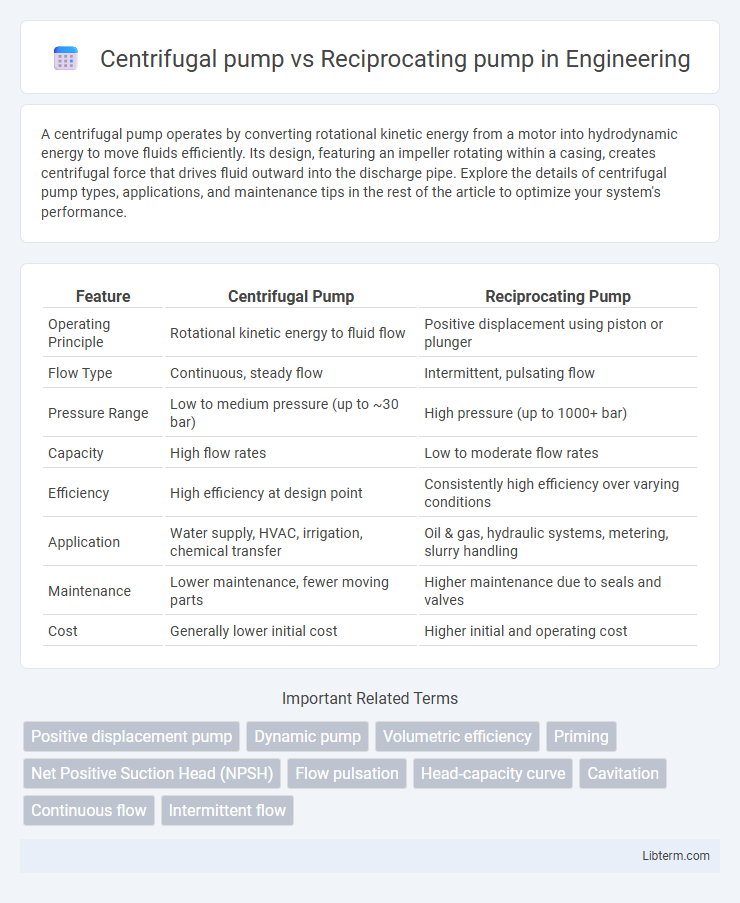

| Feature | Centrifugal Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Rotational kinetic energy to fluid flow | Positive displacement using piston or plunger |

| Flow Type | Continuous, steady flow | Intermittent, pulsating flow |

| Pressure Range | Low to medium pressure (up to ~30 bar) | High pressure (up to 1000+ bar) |

| Capacity | High flow rates | Low to moderate flow rates |

| Efficiency | High efficiency at design point | Consistently high efficiency over varying conditions |

| Application | Water supply, HVAC, irrigation, chemical transfer | Oil & gas, hydraulic systems, metering, slurry handling |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance due to seals and valves |

| Cost | Generally lower initial cost | Higher initial and operating cost |

Introduction to Centrifugal and Reciprocating Pumps

Centrifugal pumps operate by converting rotational kinetic energy to hydrodynamic energy, making them ideal for high-flow, low-viscosity fluids. Reciprocating pumps use positive displacement with a piston or diaphragm to move fluids, providing precise flow rates and high-pressure capabilities. Both pump types serve distinct industrial applications based on fluid characteristics and required pressure conditions.

Working Principle of Centrifugal Pumps

Centrifugal pumps operate by converting rotational kinetic energy, typically from an electric motor or engine, into hydrodynamic energy through an impeller that accelerates the fluid outward from the pump's center. The fluid enters the pump impeller along its axis and is propelled radially outward into a volute or diffuser casing, increasing pressure and flow velocity. This continuous flow mechanism contrasts with the intermittent volumetric displacement characteristic of reciprocating pumps.

Working Principle of Reciprocating Pumps

Reciprocating pumps operate on the positive displacement principle, using a piston or plunger that moves back and forth within a cylinder to draw fluid in through an inlet valve and push it out through an outlet valve. This back-and-forth motion creates pressure differences that enable the pump to move fluid with high precision and efficiency in low flow, high pressure applications. Unlike centrifugal pumps that rely on rotational kinetic energy, reciprocating pumps deliver a constant flow regardless of pressure variations.

Key Differences Between Centrifugal and Reciprocating Pumps

Centrifugal pumps use a rotating impeller to convert kinetic energy into fluid flow, making them ideal for handling large volumes with low viscosity liquids, whereas reciprocating pumps utilize a piston or plunger mechanism to deliver precise, high-pressure flow suitable for viscous fluids and applications requiring exact dosing. Centrifugal pumps operate continuously with a steady flow rate, while reciprocating pumps deliver pulsating flow with higher pressure capabilities and better efficiency at low flow rates. Maintenance complexity and operational cost are generally lower for centrifugal pumps compared to the more mechanically intricate and maintenance-heavy reciprocating pumps.

Advantages of Centrifugal Pumps

Centrifugal pumps offer advantages such as higher flow rates and smoother, continuous fluid delivery, making them ideal for applications requiring consistent flow. They generally have simpler construction with fewer moving parts, resulting in lower maintenance costs and improved reliability. Their capability to handle a wide range of fluids and operate efficiently at high speeds further enhances their versatility in industrial and water supply systems.

Advantages of Reciprocating Pumps

Reciprocating pumps offer high pressure output and precise flow control, making them ideal for applications requiring accurate dosing or high-pressure delivery. Their positive displacement mechanism ensures a constant volume flow regardless of pressure variations, enhancing efficiency in hydraulic systems and chemical processing. These pumps also handle viscous fluids and abrasive materials better than centrifugal pumps, extending their versatility across diverse industrial sectors.

Limitations of Centrifugal Pumps

Centrifugal pumps face limitations in handling high-viscosity fluids and maintaining efficiency at low flow rates, which reduces their suitability for heavy oil or slurry applications. They are also less effective in generating high pressure compared to reciprocating pumps, making them challenging for tasks requiring precise pressure control. Additionally, centrifugal pumps may experience cavitation and wear issues under conditions of varying flow or when pumping fluids with entrained gases.

Limitations of Reciprocating Pumps

Reciprocating pumps face limitations such as pulsating flow, which causes vibrations and noise, reducing system efficiency. Their complex design involves numerous moving parts, leading to higher maintenance costs and increased wear. These pumps are also less suitable for handling high flow rates or fluids with suspended solids, limiting their application in certain industrial processes.

Applications and Industry Suitability

Centrifugal pumps excel in high-flow, low-viscosity fluid applications such as water treatment, chemical processing, and HVAC systems, favored for their continuous and smooth flow delivery. Reciprocating pumps are ideal for industries requiring precise volumetric flow and high-pressure output, including oil and gas, pharmaceuticals, and hydraulic systems where accurate dosing and handling of viscous or abrasive fluids are critical. The selection between centrifugal and reciprocating pumps hinges on the specific pressure, flow rate, and fluid characteristics dictated by industry demands.

Which Pump to Choose: Centrifugal vs Reciprocating

Choosing between a centrifugal pump and a reciprocating pump depends on the application requirements, flow rate, and pressure needs. Centrifugal pumps excel in handling high flow rates with low to moderate pressure, making them ideal for water supply and circulation systems. Reciprocating pumps provide high pressure at low flow rates, suitable for precise dosing, hydraulic systems, and applications requiring consistent pressure regardless of flow variations.

Centrifugal pump Infographic

libterm.com

libterm.com