Yield strength measures the maximum stress a material can withstand without permanently deforming, playing a critical role in engineering and construction applications. Understanding your material's yield strength is essential for ensuring safety, durability, and performance in structural designs. Explore the rest of the article to learn how yield strength influences material selection and design decisions.

Table of Comparison

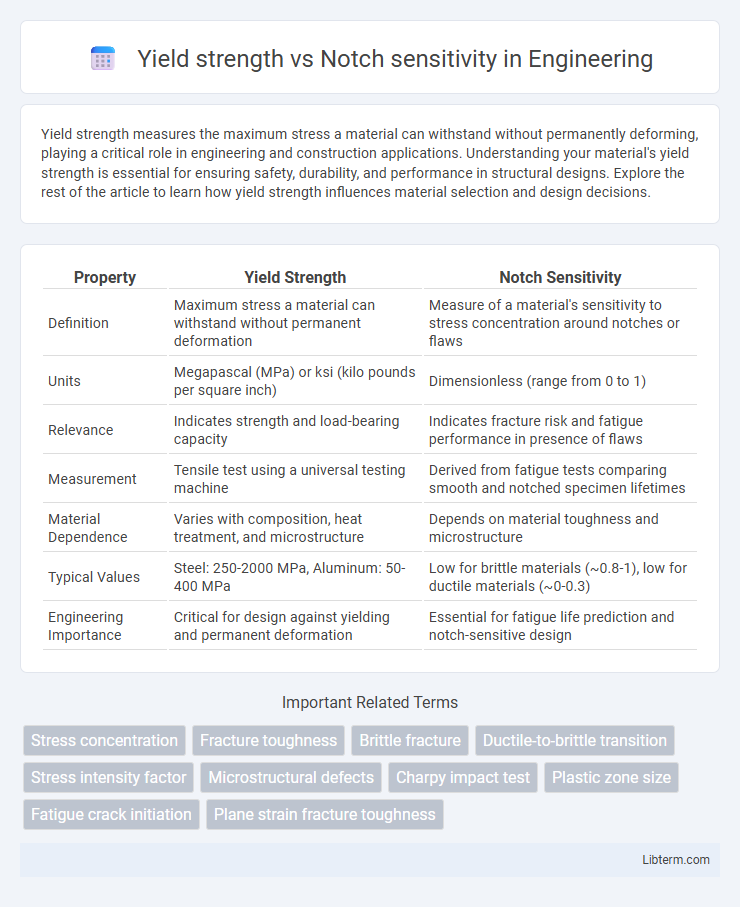

| Property | Yield Strength | Notch Sensitivity |

|---|---|---|

| Definition | Maximum stress a material can withstand without permanent deformation | Measure of a material's sensitivity to stress concentration around notches or flaws |

| Units | Megapascal (MPa) or ksi (kilo pounds per square inch) | Dimensionless (range from 0 to 1) |

| Relevance | Indicates strength and load-bearing capacity | Indicates fracture risk and fatigue performance in presence of flaws |

| Measurement | Tensile test using a universal testing machine | Derived from fatigue tests comparing smooth and notched specimen lifetimes |

| Material Dependence | Varies with composition, heat treatment, and microstructure | Depends on material toughness and microstructure |

| Typical Values | Steel: 250-2000 MPa, Aluminum: 50-400 MPa | Low for brittle materials (~0.8-1), low for ductile materials (~0-0.3) |

| Engineering Importance | Critical for design against yielding and permanent deformation | Essential for fatigue life prediction and notch-sensitive design |

Introduction to Yield Strength and Notch Sensitivity

Yield strength defines the maximum stress a material can withstand before permanent deformation occurs. Notch sensitivity measures how susceptible a material is to crack initiation and failure at stress concentrators like notches or grooves. Understanding the relationship between yield strength and notch sensitivity is crucial for predicting material performance under real-world loading conditions.

Defining Yield Strength in Materials

Yield strength in materials refers to the stress level at which a material begins to deform plastically, marking the transition from elastic to permanent deformation. Notch sensitivity measures how the presence of stress concentrators, such as notches or cracks, affects the yield strength by lowering the stress required to initiate yield. Materials with high notch sensitivity exhibit a pronounced reduction in yield strength due to localized stress concentrations, impacting structural integrity under load.

Understanding Notch Sensitivity

Yield strength defines the stress level at which a material begins to deform plastically, while notch sensitivity measures how susceptible that material is to stress concentrations caused by geometric discontinuities like notches or cracks. Understanding notch sensitivity is crucial for predicting failure modes in high-stress applications, as materials with high notch sensitivity exhibit significant reductions in effective strength and toughness near defects. Engineers assess notch sensitivity using the notch sensitivity factor (q), which ranges from 0 (notch-insensitive) to 1 (fully notch-sensitive), guiding material selection and design to mitigate fracture risks.

Relationship Between Yield Strength and Notch Sensitivity

Materials with higher yield strength often exhibit increased notch sensitivity due to their limited capacity for plastic deformation near stress concentrations. The abrupt presence of a notch amplifies local stress, causing brittle materials with high yield strength to fail prematurely. Consequently, a direct correlation exists where increased yield strength typically elevates notch sensitivity, reducing a material's resistance to crack initiation at notched regions.

Factors Influencing Yield Strength

Yield strength is significantly influenced by material composition, heat treatment, and microstructural characteristics such as grain size and phase distribution. Notch sensitivity impacts yield strength by localizing stress concentrations, which can reduce the material's effective yield strength especially in brittle materials with low ductility. Understanding the interaction between grain boundary strengthening mechanisms and notch-induced stress risers is essential for improving fatigue resistance and structural durability.

Factors Affecting Notch Sensitivity

Yield strength significantly influences notch sensitivity by determining a material's ability to resist localized deformation at stress concentrators. Factors affecting notch sensitivity include material hardness, grain size, microstructure, and temperature, which alter the stress distribution around notches. Higher yield strength materials typically exhibit increased notch sensitivity due to reduced plastic deformation capacity near notches.

Impact of Notches on Yield Strength

Notches significantly decrease yield strength by concentrating stress at specific points, which accelerates the initiation of plastic deformation under load. Materials with higher notch sensitivity exhibit greater reductions in yield strength, as the localized stress intensification promotes early yielding around the notch area. Engineering designs must account for this relationship to ensure structural integrity and prevent premature failure in components with geometric discontinuities.

Material Selection: Yield Strength vs. Notch Sensitivity

Yield strength is a critical factor in material selection as it indicates the maximum stress a material can withstand without permanent deformation, directly influencing structural integrity. Notch sensitivity measures a material's susceptibility to stress concentration around geometric discontinuities, impacting its fracture resistance and fatigue life. Balancing high yield strength with low notch sensitivity is essential for optimizing performance in applications subjected to dynamic loads and stress risers.

Testing Methods for Yield Strength and Notch Sensitivity

Yield strength is commonly measured using tensile testing methods such as ASTM E8, which involves applying controlled stress to a specimen until plastic deformation begins. Notch sensitivity is assessed through impact testing techniques like Charpy or Izod tests, evaluating material performance in the presence of stress concentrators or geometric discontinuities. Combining tensile and impact tests provides critical insights into the relationship between yield strength and a material's susceptibility to notch-induced failure.

Engineering Applications and Case Studies

Yield strength significantly influences notch sensitivity in engineering applications, as materials with higher yield strength often exhibit increased susceptibility to notch-induced stress concentrations. Case studies in aerospace and automotive components demonstrate that alloys with optimized yield strength can reduce notch sensitivity, enhancing fatigue resistance and structural reliability. Designing components with appropriate heat treatments and surface finishing further mitigates the adverse effects of notches, improving overall performance under cyclic loading conditions.

Yield strength Infographic

libterm.com

libterm.com